180g Fully Automatic Canned Fish Production Line - Chinese Manufacturer, Factory, Supplier

As global demand for premium canned seafood continues to rise, processors require advanced solutions to maintain consistency, efficiency, and profitability. The 180g Fully Automatic Canned Fish Production Line is designed to meet these challenges by integrating every step of production into a seamless, high-speed operation. With its precision engineering and cutting-edge automation, this system enables producers to deliver perfectly portioned 180-gram cans at an industrial scale.

From raw fish reception to final packaging, each stage is meticulously coordinated. The line includes sorting, cleaning, cutting, pre-cooking, filling, sealing, sterilizing, and labeling. Automated weighing systems guarantee exact 180-gram portions, eliminating product giveaway and ensuring compliance with international quality standards. The advanced sealing technology creates an airtight, secure closure that preserves flavor, texture, and nutritional value while extending shelf life.

Constructed from premium food-grade stainless steel, the production line is built for durability and hygienic processing. Its modular design allows for customization, enabling processors to adapt equipment configurations for different fish species or packaging formats. Real-time monitoring systems provide operators with detailed data insights, improving quality control and minimizing downtime.

Partnering with a trusted china manufacturer offers significant advantages in terms of cost efficiency and tailored solutions. Many of these manufacturers provide end-to-end services, including equipment customization, installation, operator training, and prompt after-sales support. This ensures that production facilities can run smoothly with minimal interruptions while maintaining high operational standards.

The 180g Fully Automatic Canned Fish Production Line is an essential investment for seafood processors seeking to expand capacity, reduce labor dependency, and enhance product uniformity. By combining advanced automation with rigorous safety compliance, it empowers businesses to meet growing consumer demand and strengthen their competitiveness in the global seafood market.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

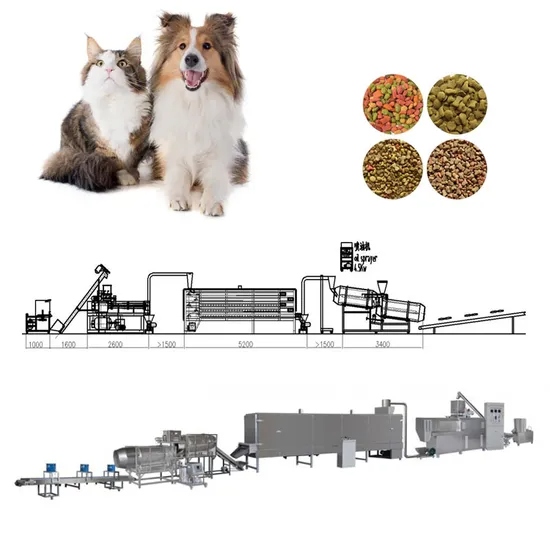

Meat Canned Food Production Line Dry Pet Food Production Line

Dry Pet Food Production Line Automatic Belt Frying Machine

Automatic Belt Frying Machine Fish Speed Cleaning Machine

Fish Speed Cleaning Machine YL-980 Digital Metal Detector

YL-980 Digital Metal Detector Gummy Candy Production Line

Gummy Candy Production Line Brush Potato Washing Peeling Machine

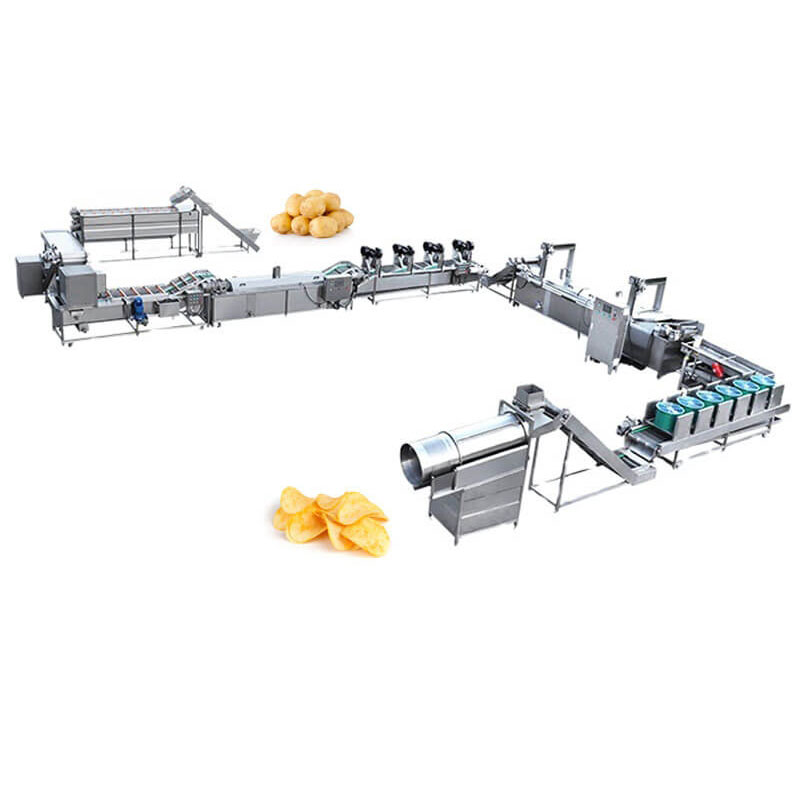

Brush Potato Washing Peeling Machine Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Biscuit Line

Biscuit Line