Tomato Processing Line - Chinese Manufacturer, Factory, Supplier

The tomato processing line is a complete industrial solution designed to transform fresh tomatoes into a wide range of finished products such as tomato paste, ketchup, sauce, juice, and puree. With advanced automation and precise control systems, it ensures high production efficiency, consistent product quality, and compliance with global food safety standards.

This production line typically includes several key sections: washing and sorting, crushing, pulping and refining, concentration, sterilization, and aseptic filling. Each stage is optimized for maximum yield and minimal product loss. Constructed from high-grade stainless steel, all equipment is resistant to corrosion and easy to clean, ensuring hygiene and long-term reliability in continuous operation.

Depending on customer requirements, the line can be customized for different production capacities, from small-scale plants to large industrial operations. Optional modules such as vacuum evaporators, blending tanks, CIP cleaning systems, and automatic packaging units can be integrated for full automation. The system is suitable for both hot break and cold break processing methods, ensuring flexibility for various tomato-based product formulations.

Applications include tomato paste factories, sauce and ketchup manufacturers, beverage producers, and food ingredient suppliers. With precise temperature control and efficient energy use, the line helps reduce operational costs and improves overall ROI.

Qingdao Hongshengyuanlin Co., Ltd. is a professional manufacturer and exporter of tomato processing lines, offering turnkey engineering solutions from plant design, equipment fabrication, and installation to operator training and after-sales support. With years of global project experience, the company provides customized tomato processing systems that meet the specific needs of clients across Asia, the Middle East, Africa, and South America — ensuring reliability, efficiency, and stable performance in every production environment.

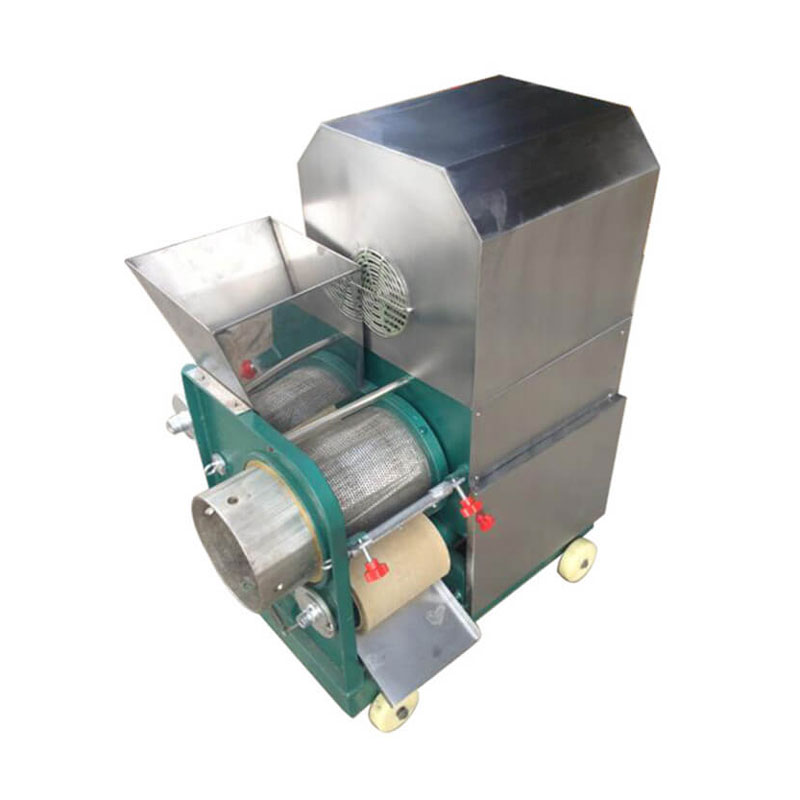

Small Scale Tomato Sauce Making Machine

Small Scale Tomato Sauce Making Machine Tomato Sauce Milling Machine

Tomato Sauce Milling Machine Tomato Sauce Grinding Machine

Tomato Sauce Grinding Machine Tomato Juice Processing Production Line

Tomato Juice Processing Production Line Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Tomato Paste Production Line

Tomato Paste Production Line Shrimp Canning Line Equipment

Shrimp Canning Line Equipment  Cooked Meat Shredder Machine

Cooked Meat Shredder Machine AP Series Flake Ice Machine

AP Series Flake Ice Machine Industrial Frozen Meat Slicing Machine

Industrial Frozen Meat Slicing Machine Fish Deboner Machine

Fish Deboner Machine Pork Skin Removing Machine

Pork Skin Removing Machine Standard Vertical Weighing and Packaging System

Standard Vertical Weighing and Packaging System