1. Overview

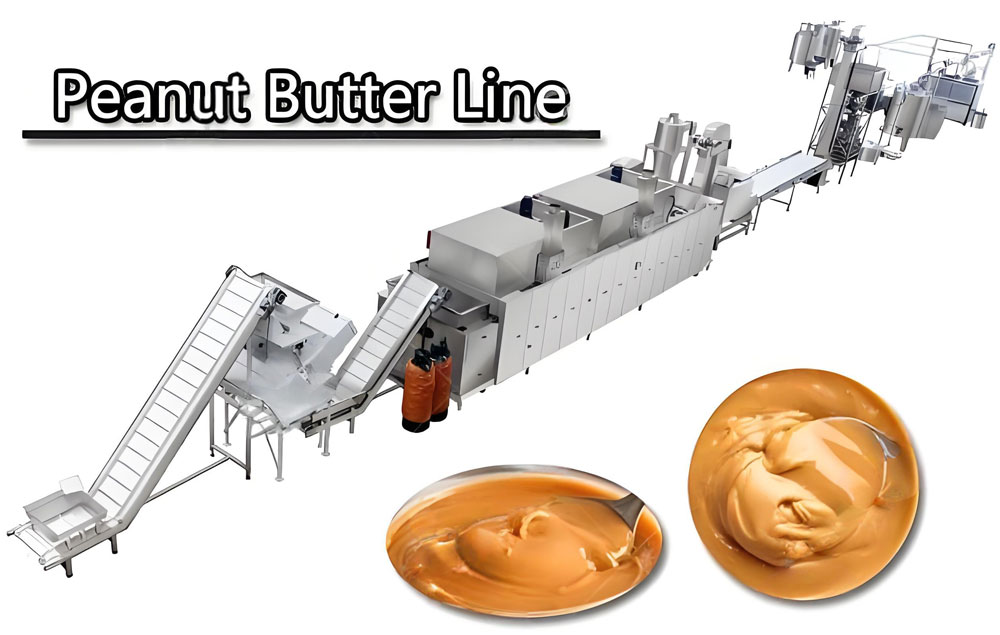

The Peanut Butter Production Line is a fully automatic processing system designed for the continuous production of smooth, crunchy, and flavored peanut butter.

It integrates roasting, peeling, grinding, mixing, homogenizing, cooling, and filling into one streamlined line, ensuring consistent quality, hygiene, and high efficiency.

This line is suitable for food factories, nut processing plants, and condiment manufacturers that require high productivity, stable operation, and compliance with food safety standards.

2. Process Flow

Raw Peanut Feeding

Clean peanuts are loaded into the system for automatic continuous processing.Roasting

Peanuts are evenly roasted using hot air or rotary drum roasters to develop aroma and flavor.Cooling & Peeling

Rapid cooling ensures crisp texture; skin is removed efficiently by air friction or roller peeling.Grinding (Primary & Fine)

Two-stage colloid mills grind peanuts into fine paste, achieving a particle size of 50–70 microns.Mixing & Homogenizing

Sugar, salt, oil, or stabilizers are added and mixed evenly; homogenizer ensures smooth texture.Cooling

Paste is cooled to a stable temperature to maintain flavor and consistency.Filling & Packaging

The finished peanut butter is filled into jars, bottles, or pouches using precise servo-driven fillers.

3. Production Capacity

| Model | Capacity | Power | Suitable For |

|---|---|---|---|

| PB-300 | 300 kg/h | 35 kW | Small plants / pilot lines |

| PB-500 | 500 kg/h | 55 kW | Medium-scale factories |

| PB-1000 | 1,000 kg/h | 90 kW | Industrial peanut butter plants |

(Custom configurations for almond butter, sesame paste, and hazelnut cream available.)

4. Main Equipment Configuration

| Equipment | Function | Highlights |

|---|---|---|

| Peanut Roaster | Roasting peanuts | Electric/gas heating, uniform temperature 160–180°C |

| Cooling Conveyor | Rapid cooling | Air-cooled stainless conveyor, gentle handling |

| Peeling Machine | Remove skin | Rubber roller type, high peeling rate >98% |

| Colloid Mill (2-stage) | Grinding | Adjustable fineness, precision rotor-stator system |

| Mixing Tank | Ingredient blending | SUS304, automatic dosing & heating |

| Homogenizer | Texture refinement | Smooth, uniform paste structure |

| Cooling System | Temperature control | Water-cooled or air-cooled jacket tank |

| Filling Machine | Final packaging | Servo-driven, anti-drip nozzles |

| Labeling & Capping Line | Final process | Fully automatic integration optional |

5. Technical Features

✅ High Automation: Fully integrated PLC control minimizes manual operation.

✅ Hygienic Design: All contact parts made of SUS304/316L stainless steel, meeting CE & HACCP standards.

✅ Precision Grinding: Adjustable fineness for both smooth and crunchy types.

✅ Stable Operation: Continuous process ensures consistent quality and yield.

✅ Energy Efficiency: Heat recovery between roasting and cooling reduces energy cost by 20%.

✅ Easy Cleaning: CIP system for sanitary maintenance and quick product changeover.

✅ Versatile Applications: Suitable for peanut butter, sesame paste (tahini), almond butter, and nut spreads.

6. Technical Specifications (Example: PB-500 Line)

| Item | Specification |

|---|---|

| Capacity | 500 kg/hour |

| Power Supply | 380V / 50Hz / 3Ph |

| Total Power | 55 kW |

| Material | SUS304 stainless steel |

| Grinding Fineness | 50–70 microns |

| Roasting Temperature | 160–180°C |

| Cooling Temperature | <40°C |

| Control System | Siemens PLC + Touchscreen |

| Automation Level | Fully automatic |

| Dimensions | 18 × 2 × 3 m (approx.) |

7. Optional Modules

Flavor injection system (for chocolate or honey peanut butter)

Vacuum degassing system

Nitrogen-flushing filling unit

Automatic jar washing & drying system

Automatic capping and labeling line

Online viscosity and temperature monitoring

8. Quality & Compliance

Certified by CE / ISO9001 / HACCP / GMP

Food-contact materials compliant with FDA standards

Complies with EU Machinery Directive (2006/42/EC)

Optional UL certification for North American customers

9. ROI & Performance

Labor Saving: Up to 60% reduction in manual handling

Energy Efficiency: 15–25% lower power consumption

Consistent Output: Yield accuracy ±1%

Low Maintenance Cost: Modular components, long service life

ROI Period: 12–18 months for mid-sized installations

10. Engineering & Customization

Turnkey project design from raw peanuts to packaged products

2D/3D factory layout planning

Recipe adjustment & texture customization (smooth / crunchy)

Integration with existing food production systems

On-site installation & operator training

11. After-Sales Support

24/7 technical assistance (online & offline)

Global spare parts supply

Preventive maintenance plans

Recipe optimization & product upgrade services

Long-term engineering partnership

12. Summary

The Peanut Butter Production Line provides an efficient, hygienic, and flexible solution for nut paste manufacturing.

With advanced automation, precision grinding, and consistent product quality, it helps manufacturers reduce costs, improve yield, and scale production effectively.

It is the ideal investment for businesses targeting stable, large-scale peanut butter production and product diversification.

Must-read blogs for bosses