🏭 Product Overview

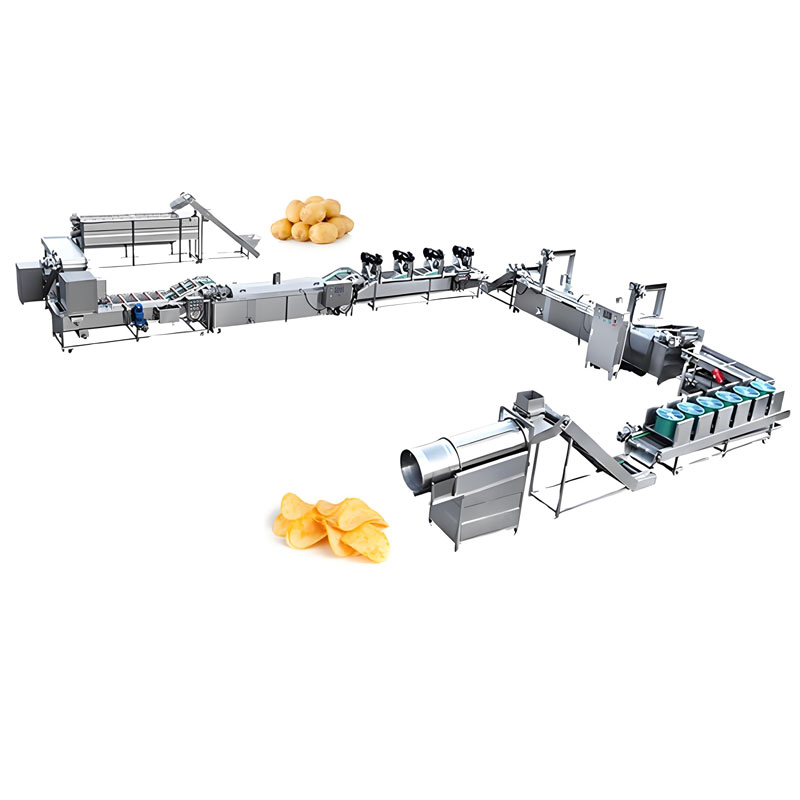

The Potato Chips Production Line is a complete automatic system designed for producing high-quality fried potato chips and crisps at industrial scale.

From raw potato washing to slicing, frying, flavoring, and packaging, each stage is carefully engineered to maintain the natural flavor, golden color, and crisp texture of the chips while ensuring production efficiency and hygiene.

This line is widely used in snack food factories, potato processing plants, and contract manufacturing facilities, supporting both small-scale startups and large continuous production projects.

⚙️ Complete Processing Flow

1️⃣ Potato Washing & Peeling

Automatic bubble washing machine removes mud and impurities.

Brush peeling machine gently removes potato skins without damaging flesh.

Made of 304 stainless steel, ensuring long service life and hygiene compliance.

Adjustable peeling strength according to potato type and freshness.

2️⃣ Cutting & Rinsing

High-speed potato slicer produces uniform slices (0.8–2.0mm adjustable).

Optional wave-cutting blades for ripple-style chips.

Continuous rinsing tank removes starch to prevent chips from sticking during frying.

Water recycling system saves up to 30% on water usage.

3️⃣ Blanching & De-watering

Hot-water blanching machine inactivates enzymes, preserves color, and improves texture.

Automatic temperature control between 85–95°C.

De-watering machine (centrifugal or air-blower type) ensures uniform drying before frying to enhance oil stability and reduce consumption.

4️⃣ Frying System

Continuous frying machine available in electric, gas, or diesel heating versions.

Oil temperature precisely controlled between 160–180°C.

Multi-layer mesh belt prevents chips overlap, ensuring even frying color.

Oil filtration system extends oil life and keeps products clean and golden.

Optional vacuum frying for low-oil, healthy snack production.

5️⃣ De-oiling, Flavoring & Cooling

Centrifugal de-oiling system removes excess surface oil after frying.

Rotary seasoning drum with powder or liquid sprayer for uniform flavoring (salt, BBQ, cheese, chili, etc.).

Cooling conveyor reduces chip temperature before packaging, preventing condensation.

6️⃣ Packaging Section

Automatic weighing and packing machine compatible with pillow bags, nitrogen-filled bags, or stand-up pouches.

Nitrogen flushing system extends shelf life and keeps chips crispy.

Optional metal detector and check weigher for food safety and quality assurance.

🧠 Key Features & Advantages

✅ Full Automation – From washing to packing, all stages run continuously with PLC control.

✅ Energy Efficiency – Heat recovery system saves up to 25% energy in frying and blanching.

✅ Uniform Quality – Advanced slicer and fryer maintain even thickness, color, and texture.

✅ Hygienic Design – All contact parts made of SUS304 stainless steel, with CIP cleaning function.

✅ Flexible Capacity Options – From 100 kg/h small line to 1000 kg/h industrial production.

✅ Easy Maintenance – Modular components and ergonomic layout for quick cleaning and repair.

✅ Stable Oil Management – Continuous filtration reduces oil oxidation and production cost.

✅ Flavor Flexibility – Adaptable for various seasonings, including sweet, salty, and spicy flavors.

📊 Technical Specifications

| Model | Capacity (kg/h) | Heating Method | Power (kW) | Dimension (mm) |

|---|---|---|---|---|

| YL-PCL-100 | 100 | Electric / Gas | 35 | 9000×1800×2200 |

| YL-PCL-200 | 200 | Gas / Diesel | 48 | 12000×2000×2300 |

| YL-PCL-300 | 300 | Gas | 60 | 15000×2200×2400 |

| YL-PCL-500 | 500 | Gas / Diesel | 78 | 18000×2500×2600 |

| YL-PCL-1000 | 1000 | Gas | 120 | 22000×3000×2800 |

(Custom capacity & layout design available for different factory spaces.)

🍟 Available Product Types

| Product Category | Examples |

|---|---|

| Regular Potato Chips | Thin, golden, crispy slices |

| Ripple Chips | Wave-style, thicker texture |

| Low-Oil Chips | Vacuum-fried, healthier snacks |

| Flavored Chips | BBQ, Cheese, Onion, Chili, Sea Salt |

| Sweet Potato Chips | Alternative root-based snacks |

🧩 Optional Machines

| Equipment | Function |

|---|---|

| Elevator Conveyor | Transports potatoes or chips between stages |

| Oil Filtering System | Extends frying oil lifespan |

| Vacuum Frying Machine | Produces low-oil, high-nutrition chips |

| Seasoning Mixer | Uniformly blends multiple flavor powders |

| Nitrogen Flushing System | Ensures long shelf life |

| Metal Detector | Detects foreign metal contamination |

| Automatic Palletizer | Improves end-of-line efficiency |

🏭 Applications

This production line is suitable for:

Snack food manufacturers

Frozen or dehydrated potato processors

Ready-to-eat food plants

Contract OEM snack producers

Export-oriented factories

The line supports both domestic market mass production and export-grade snack manufacturing.

💡 Investment & ROI Value

Energy & Oil Saving: Filtration and heat recovery reduce operation cost by 20–30%.

Labor Efficiency: 2–3 operators can manage the entire line.

High Yield Rate: >98% finished product rate with minimal breakage.

Fast Payback: Most clients achieve ROI within 12–16 months.

Market Flexibility: Easily switch between potato, sweet potato, or banana chips production.

🌍 Why Choose Our Potato Chips Line

✔ Over 15 years of experience in food frying systems

✔ Exported to 60+ countries (Asia, Europe, Middle East, Africa, South America)

✔ Turnkey plant design from washing to packaging

✔ CE / ISO / HACCP / GMP certified

✔ Professional after-sales service & remote support

✔ Available in semi-automatic or fully automatic configurations

🧾 Typical Line Composition

Potato Washing & Peeling Machine

Elevator Conveyor

Cutting & Rinsing Unit

Blanching Machine

De-watering Machine

Continuous Fryer

De-oiling & Cooling System

Seasoning Drum

Weighing & Packing Machine

💬 Customer Feedback

“The line operates smoothly, and the chips have consistent color and crispness. Energy consumption is 25% lower than our previous system.”

— Snack Factory, Saudi Arabia

“We use this line for both potato and banana chips. Quick recipe change and simple cleaning make daily production easy.”

— Food Processor, Indonesia

📞 Contact Us

Planning to build or upgrade your potato chips production factory?

Our engineering team provides custom layout design, capacity planning, and full turnkey solutions to meet your market demands.

Must-read blogs for bosses