🌍 Overview

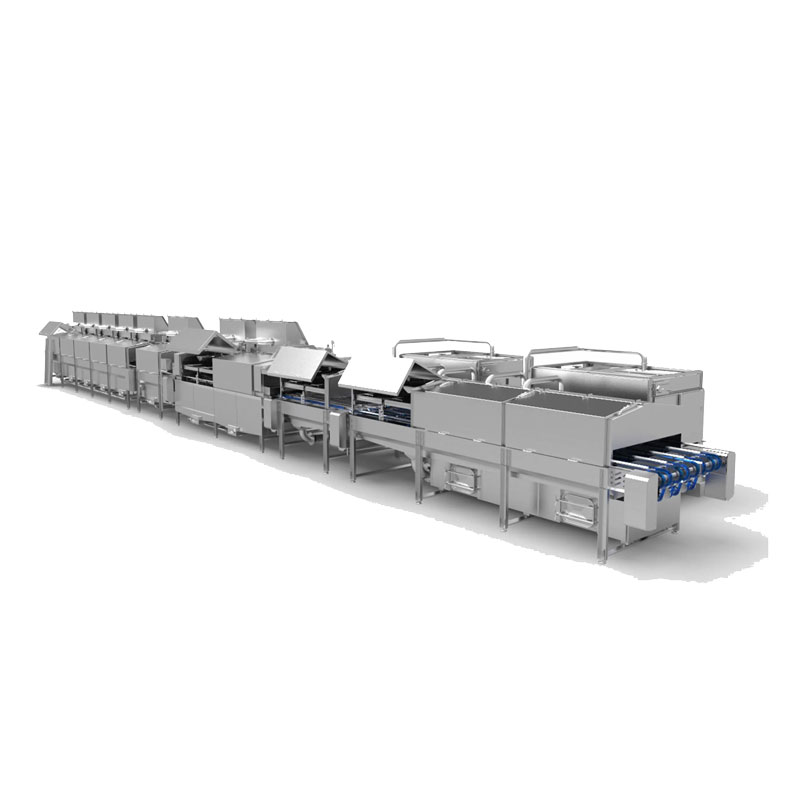

The Shrimp Processing Line is an integrated, hygienic, and scalable solution for handling raw, cooked, or value-added shrimp products. From receiving to freezing and packaging, the line is fully modular, supporting a wide variety of processing needs including P&D shrimp, butterfly-cut, breaded, and IQF shrimp. Designed in compliance with international standards (HACCP, FDA, ISO22000, CE), it serves export-oriented seafood processors worldwide.

📊 Capacity Range: 500–5,000 kg/h

📦 Product Formats: Head-on, Headless, P&D, Cooked, Butterfly, Skewered, IQF, Block-Frozen

🧊 Applicable Shrimp Varieties

Vannamei / Whiteleg shrimp

Black Tiger shrimp

Freshwater shrimp

Sea-caught shrimp

Wild or aquaculture grade

🏭 Processing Flow Overview & Equipment

🔁 Processing Flow Layout (Text-based Overview)

[1] Reception & Washing → [2] Grading & Sorting → [3] Deheading & Peeling (Optional) → [4] Deveining / Butterfly Cutting → [5] Cooking / Blanching (Optional) → [6] Cooling → [7] Freezing (IQF / Plate / Spiral) → [8] Weighing & Metal Detection → [9] Packaging → [10] Cold Storage or Palletizing

Each station can be customized or skipped depending on the product type and workflow preferences.

🔧 Core Equipment & Capacities

| Process | Equipment | Capacity |

|---|---|---|

| Washing | Drum washer / Bubble washer | 500–5,000 kg/h |

| Grading | Roller grader / Optical sorter | 1,000–3,000 kg/h |

| Peeling | Mechanical peeler / manual assist | 800–3,000 kg/h |

| Deveining | Butterfly cutter / deveining blade | 500–2,000 kg/h |

| Cooking | Belt cooker / steam tunnel | 300–2,500 kg/h |

| Cooling | Counterflow cooler / ice slurry | 300–2,500 kg/h |

| Freezing | IQF / Spiral / Plate freezer | 300–5,000 kg/h |

| Packaging | Weighing + vacuum/VFFS/sealer | 10–80 packs/min |

🛠️ Customization Options

We offer complete flexibility to match your plant layout, product specs, and compliance needs:

1. Product Type Customization

P&D shrimp line

Headless / shell-on line

Cooked + IQF combo line

Breaded / battered shrimp pre-line

Block frozen or bulk shrimp packaging

2. Layout Flexibility

U-shape, straight line, or L-shape layouts

Left-to-right / right-to-left material flow

Multi-layer platforms to save floor space

Integration with existing infrastructure

3. Freezing System Options

IQF Belt Freezer: For individual pieces, sushi-grade shrimp

Spiral Freezer: For high-output in compact space

Plate Freezer: For export block-frozen styles

Optional: Cold air recycling for energy efficiency

4. Automation Levels

Semi-auto line (basic automation + manual assist)

Full-auto line (PLC + servo motors + sensors)

Smart factory ready (SCADA, data traceability, ERP/MES interface)

5. Compliance & Regional Standards

CE / UL / EAC / FDA compliance

Arabic / Spanish / Russian / French interface

Cleanroom-compatible finish (for Japan/EU buyers)

6. Value-Added Processing Modules (Optional)

Skewering machine

Coating & breading machine

Sauce injection / marination system

Auto packing with nitrogen flushing

✅ Technical Advantages

| Feature | Advantage |

|---|---|

| Sanitary Design | Full SS304/316L construction, open-frame for washdown |

| Yield Optimization | Precision peeling/cutting to minimize product loss |

| Labor Saving | Reduce manual handling by up to 70% |

| Temperature Control | Fully digital tracking of cooking & freezing curves |

| Traceability Ready | Batch tracking, labeling & QR system support |

| Modular Integration | Upgrade or add stations as your demand grows |

💼 ROI & Business Case

| Metric | Benefit |

|---|---|

| ROI Period | 12–18 months (avg. for medium line) |

| Labor Savings | $30K–$80K/year per shift (estimated) |

| Yield Improvement | Up to 5–10% more saleable shrimp per batch |

| Shelf Life | IQF = 12–24 months at -18°C |

| Certification | Fast HACCP/BRC/FDA audit readiness |

📍 Case Study: 3,000 kg/h Shrimp Line in Vietnam

Products: P&D and cooked IQF shrimp

Line: Reception → Peeling → Deveining → Cooking → Spiral Freezing → Packaging

Results:

Labor cost reduced by 48%

IQF efficiency improved shelf appeal

Export approval to EU and Japan within 4 months

Payback in 15 months

📦 Package Includes

Full equipment suite + accessories

Control system (PLC + HMI)

Installation layout & P&ID diagram

Operation + Maintenance manuals

Commissioning & training (on-site or remote)

Spare parts for 12–18 months

Certificates (CE, ISO, material traceability)

🧭 Optional Add-Ons

🧼 CIP System for automated sanitation

🧊 Ice-making systems integration

🧑🏫 Worker training manuals + video tutorials

🧾 BOM + cost structure breakdown for funding applications

📈 Business plan support (for new startups)

🤝 Let’s Build Your Shrimp Processing Line

We help seafood processors scale up with smart, compliant, and high-efficiency production systems. Contact our engineering team to:

🏗️ Design a custom factory layout

📊 Get a cost-benefit simulation

📄 Prepare your full solution proposal (quote + 3D layout + timeline)

👉 Request Your Shrimp Processing Line Proposal Now

Must-read blogs for bosses