Fruit Canned Food Production Line - Chinese Manufacturer, Factory, Supplier

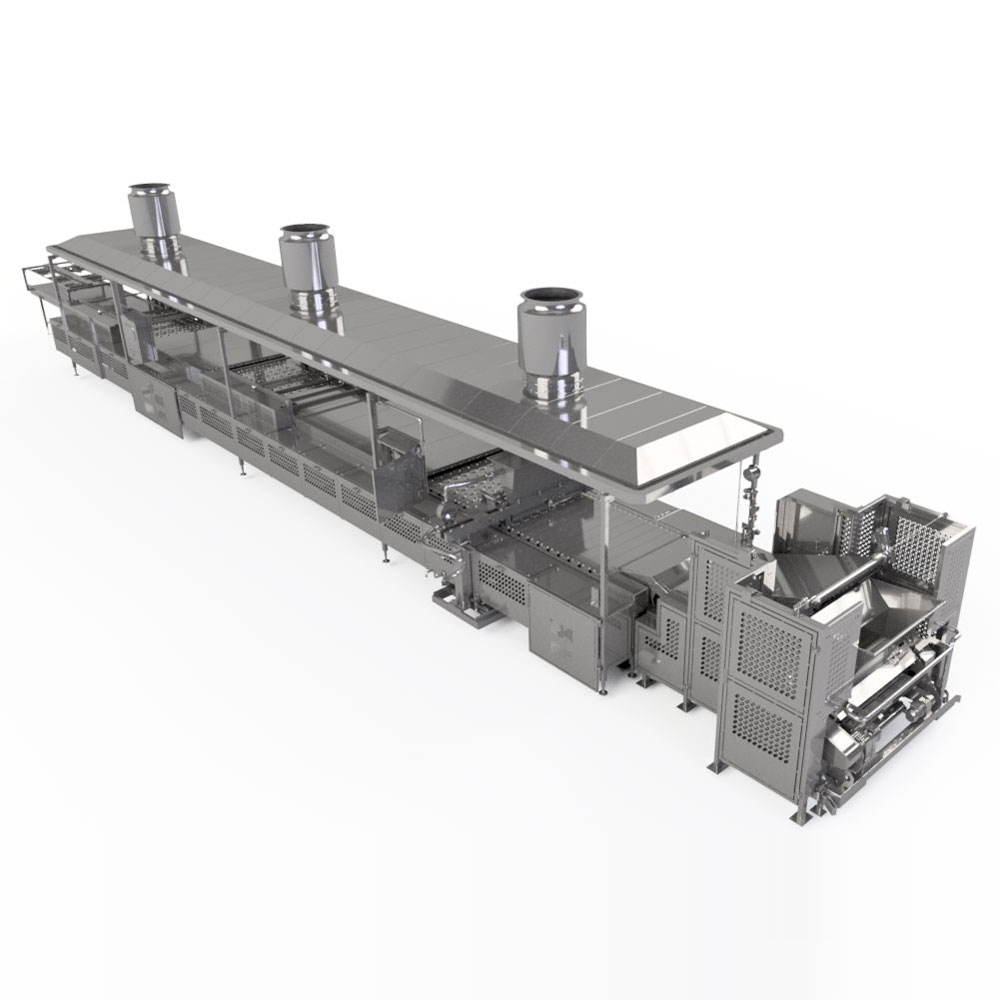

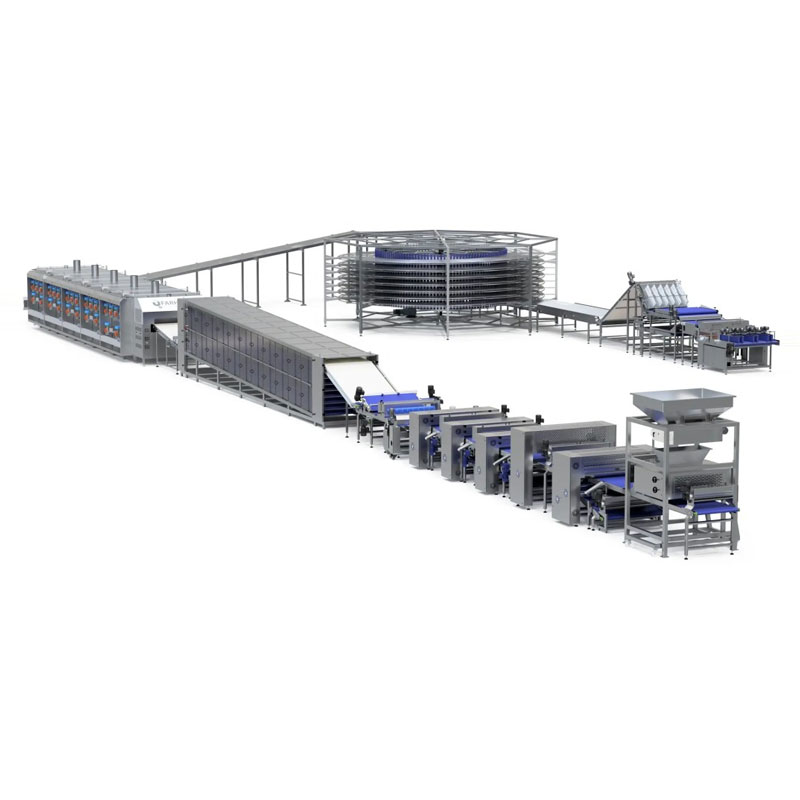

The fruit Canned Food Production Line is a comprehensive and fully automated system designed to transform fresh fruit into shelf-stable, ready-to-eat canned products. Engineered for efficiency, safety, and quality control, this line streamlines the entire process from raw fruit selection to final packaging, ensuring products meet international standards while retaining natural flavor, color, and nutritional value.

The production begins with careful fruit sorting, washing, and peeling, followed by cutting and grading to ensure uniformity. Depending on the recipe, fruits can be processed into slices, cubes, or purees before moving to blanching and syrup preparation. Precision filling machines then place the fruit and syrup into cans or jars, maintaining strict control over portion sizes and liquid levels. Advanced sealing systems create airtight closures, while retort sterilization equipment eliminates harmful microorganisms and extends shelf life without chemical preservatives.

This fruit canned food production line is highly versatile, capable of handling a wide range of products such as peaches, pineapples, pears, lychees, mangoes, and mixed fruit cocktails. The system also supports multiple packaging formats, including tin cans, glass jars, and modern retort pouches, making it adaptable to diverse market demands. Modular design allows food manufacturers to adjust capacity easily, whether for small-scale specialty production or high-volume industrial output.

Efficiency and sustainability are core advantages. Automated monitoring ensures accurate temperature and pressure control during sterilization, reducing energy consumption while safeguarding food quality. Precise dosing technology minimizes raw material waste, while hygienic stainless-steel construction facilitates easy cleaning and compliance with HACCP, ISO22000, and GMP standards. These features not only improve operational performance but also strengthen brand reputation in competitive markets.

As global demand for healthy, convenient, and long-shelf-life fruit products continues to expand, the fruit canned food production line offers food processors a reliable path to scale production, enhance profitability, and capture new market opportunities. By combining modern automation with strict food safety compliance, it ensures the consistent delivery of premium canned fruits that appeal to both domestic consumers and international buyers.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pancake Production Line

Pancake Production Line Pita Production Line

Pita Production Line Industrial Frozen Meat Slicing Machine

Industrial Frozen Meat Slicing Machine Canned Fish Production Line

Canned Fish Production Line Pet Canned Food Production Line

Pet Canned Food Production Line AP Series Flake Ice Machine

AP Series Flake Ice Machine High-Speed Twisting Machine

High-Speed Twisting Machine Vacuum Stuffing Machine

Vacuum Stuffing Machine