Overview

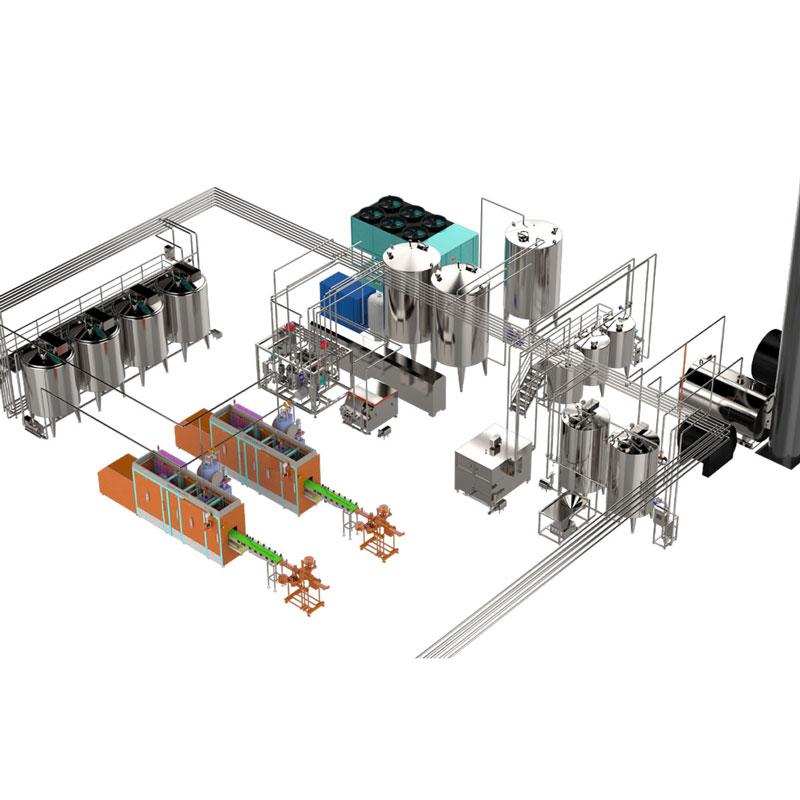

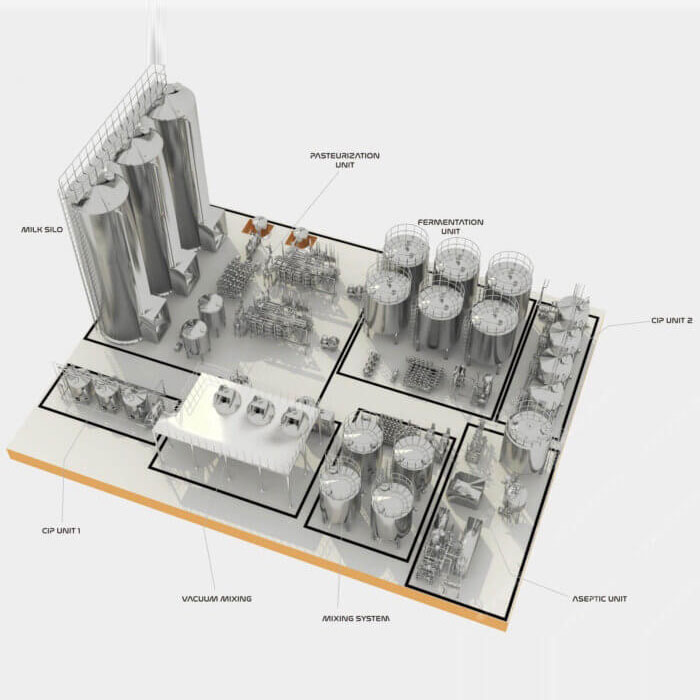

Our Yogurt Production Line is an advanced turnkey solution for producing set yogurt, stirred yogurt, drinking yogurt, and flavored yogurt.

Designed for industrial dairy processors, this line ensures consistent product quality, high automation, and full compliance with HACCP, ISO22000, and CE food safety standards.

The system integrates milk preparation, homogenization, pasteurization, fermentation, cooling, and filling — providing efficient, hygienic, and flexible production of various yogurt types.

Production Flow

1️⃣ Milk Reception & Standardization

Raw milk is received and filtered through a stainless-steel milk receiving system, ensuring impurities are removed.

Fat and solids are standardized automatically to achieve the desired yogurt texture and consistency.

2️⃣ Homogenization

A high-pressure homogenizer breaks milk fat globules to enhance mouthfeel and prevent cream separation — resulting in smooth and uniform yogurt.

3️⃣ Pasteurization

Milk is pasteurized at 85–90°C for 15–30 seconds to eliminate harmful microorganisms and denature proteins, improving gel formation during fermentation.

4️⃣ Cooling & Inoculation

After pasteurization, milk is rapidly cooled to 42–45°C, and starter cultures (e.g., Lactobacillus bulgaricus, Streptococcus thermophilus) are added precisely by dosing systems.

5️⃣ Fermentation

Fermentation takes place in insulated incubation tanks, maintaining constant temperature and gentle agitation until the target acidity and pH are reached (usually 4.4–4.6).

6️⃣ Cooling & Storage

Once fermentation is complete, yogurt is cooled to 4°C to stop bacterial activity and preserve texture. Stirred yogurt may undergo gentle mixing to achieve the desired viscosity.

7️⃣ Filling & Packaging

Automatic filling machines are used for cups, bottles, or pouches, equipped with CIP and sterilization functions, ensuring safe and contamination-free packaging.

Key Features

✅ Fully Automatic Control – PLC + touchscreen system with temperature and fermentation monitoring

✅ High Hygiene Design – All contact parts are SUS304 or SUS316L, polished to food-grade standards

✅ Stable Quality Output – Consistent texture, taste, and viscosity control

✅ Energy Efficient System – Heat recovery units and automatic CIP reduce energy and water use

✅ Flexible Product Range – Supports plain, flavored, and fruit-added yogurt

✅ Customizable Capacity – From 500 L/h to 20,000 L/h, suitable for small dairies and large factories

Technical Parameters

| Parameter | Specification |

|---|---|

| Capacity Range | 500–20,000 L/h |

| Product Type | Set / Stirred / Drinking Yogurt |

| Material | SUS304 / SUS316L Stainless Steel |

| Control System | Siemens PLC + Touch Screen |

| Heating Type | Steam / Hot Water |

| Fermentation Temperature | 42–45°C |

| Cooling Temperature | 4°C |

| CIP System | Fully Automatic |

| Voltage | 380V / 50Hz (Customizable) |

| Warranty | 12–24 Months |

Applications

Dairy product factories

Milk beverage producers

School milk and nutrition projects

Functional yogurt & probiotic drink manufacturers

Optional Equipment

Milk storage & standardization tanks

Homogenizer & pasteurizer

Fermentation tanks (insulated)

Cooling and aging tanks

Mixing system for fruit or flavor additions

Cup/bottle filling and sealing machines

CIP cleaning unit

Turnkey Yogurt Solutions

🥛 Set Yogurt Line – For solid, spoonable yogurt

🥤 Drinking Yogurt Line – For low-viscosity, ready-to-drink yogurt

🍓 Flavored Yogurt Line – For fruit, honey, or chocolate variants

🍶 Greek Yogurt Line – With additional concentration and whey separation

🧴 Aseptic Yogurt Filling System – For extended shelf-life products

Advantages

End-to-End Turnkey Service: from layout design to on-site commissioning

Modular Design: easy expansion with additional fermenters or packaging units

Precise Temperature Control: ensures optimal fermentation quality

High Production Stability: suitable for continuous operation

Comprehensive After-Sales Support: installation, training, spare parts supply

Why Choose Our Yogurt Line

✅ Over 15 years of expertise in dairy and beverage processing

✅ Customized design based on raw milk type and local market preference

✅ Energy-saving and easy-to-clean design with automatic CIP

✅ Proven installations in Asia, Africa, Europe, and South America

✅ Supports integration with filling, labeling, and packaging lines

Must-read blogs for bosses