Fish Canned Production Line Equipment Buying Guide: Expert Tips for 2025 Choices

Hey there, fellow food industry enthusiast! In the bustling world of food processing, fish canning production line equipment is your ultimate ally for whipping up efficient, safe, and top-quality products. With global seafood consumption skyrocketing—according to the United Nations Food and Agriculture Organization (FAO), we're looking at a whopping 210 million tons by 2025, and canned fish playing a starring role—picking the right gear can supercharge your output, slash costs, and keep everything compliant with international standards like HACCP, FDA, and EU food safety regs. This guide is packed with practical tips, fresh data, and insider insights to help business owners, procurement pros, newbies, or supply chain wizards like you navigate the options. Whether you're running a cozy small-scale operation or a massive export powerhouse, I've got you covered with step-by-step advice on everything from workflows to the hottest packaging trends. Let's dive in and make your production dreams come true—reading time about 15 minutes, perfect for a quick coffee break!

Overview of the Fish Canning Production Process

Before we jump into gear shopping, let's get cozy with the entire production process. It's not just about slapping machines together—it's a seamless symphony that turns fresh fish into shelf-stable delights. Understanding this will help you match equipment to your real-world needs like a pro. A typical fish canning line breaks down into five key stages, each with its own equipment must-haves. I'll walk you through it warmly, so you feel confident every step of the way.

Raw Material Receiving and Initial Handling: This kicks off when your fish arrives—think unloading, weighing, and a quick quality check. Fresh catches like tuna, sardines, or salmon need speedy handling in a cool environment to keep bacteria at bay. Equipment here includes hydraulic unloaders and auto-weighing systems that whisk fish from trucks or boats straight onto the line, minimizing human touch. For big fish like tuna, these unloaders can handle tons per hour without a hitch. Fun fact: Nailing this stage can boost your overall efficiency by 15-20%, per 2025 industry reports.

Cleaning and Pre-Processing: Time to scrub up! Fish get a thorough wash, heads and guts removed, graded, and cut into pieces. Automated washers use high-pressure sprays and brushes to zap scales, dirt, and parasites while keeping the meat fresh and juicy. Pre-processing might involve steaming or marinating for that extra flavor punch and longer shelf life. For smaller fish like sardines, continuous conveyor sorters auto-classify by size, dodging contamination from manual work. This phase eats up about 20% of your equipment budget but sets the tone for quality downstream.

Filling and Canning: Now the fun part—stuffing those prepped fish pieces with sauce, oil, or brine into cans. Quantitative fillers ensure every can hits the mark (say, a standard 200g tin) with pinpoint accuracy, down to ±1g, so no waste. Modern setups handle multi-head filling at up to 200 cans per minute, ideal for busy factories. It's all about hygiene here, with enclosed systems to keep contaminants out.

Sealing, Sterilization, and Cooling: Once filled, cans get vacuum-sealed to boot out air, then popped into high-pressure retorts for sterilization (typically 121°C for 15-20 minutes) to hit the right F-value and wipe out nasties like botulism. Coolers then bring them down to room temp fast, avoiding any can-warping heat stress. The whole shebang needs tight temp and pressure monitoring to meet food safety gold standards.

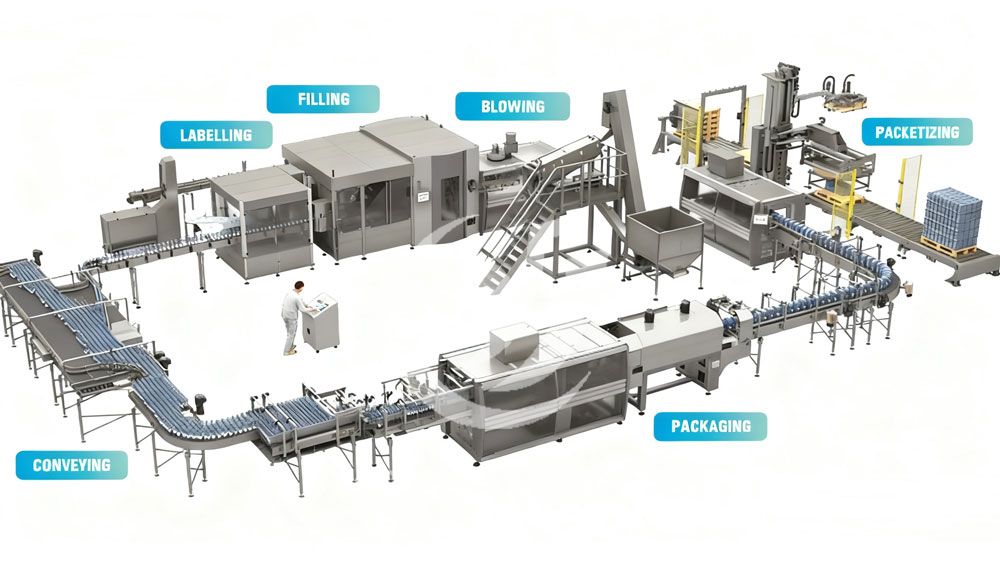

Post-Processing and Packaging: Wrapping it up with labeling, inspections (like X-ray for foreign objects), and outer packing. Automation shines here for that polished look and smooth logistics. Tie it all together with a PLC (Programmable Logic Controller) system for real-time oversight and data logging—super handy for traceability and tweaks.

Grasping these steps lets you spot equipment synergies spot-on. For instance, small outfits might thrive with semi-auto lines, while exporters need full automation to ace EU REACH rules. The global canned fish market is eyeing $45 billion by 2025—grab your slice with smart process-matched gear!

Best sellers:125g Tin Box Fish Canned Production Line

Key Equipment Types and Functions

Fish canning lines boast a variety of specialized tools, each with unique roles, specs, and fits. When shopping, focus on materials (food-grade SUS304 or SUS316 stainless steel for corrosion resistance), automation levels (manual, semi, or full), and energy smarts. I'll break it down by category with a handy table for easy comparisons—let's make this exciting and straightforward!

- Cleaning and Pre-Processing Equipment:

- Hydraulic Unloaders: Auto-unload fish from vehicles with tilt or vacuum designs. Great for frozen or live hauls, capacities from 1 to 10 tons/hour. Perk: Cuts labor and keeps fish pristine.

- Washers: High-pressure jet or bubble systems scrub away grime and bugs. Fancy versions add ozone for extra sanitizing. For premium salmon, go for temp-controlled ones to preserve tenderness.

- De-Gutting and Cutting Machines: Auto-blades precisely remove innards and heads. Corrosion-proof blades zoom at hundreds of fish per minute. Stats show these slash pre-processing time by 40%—awesome efficiency boost!

- Filling and Canning Equipment:

- Quantitative Fillers: Weighing or volumetric types for even fish and liquid distribution. Handles sticky sauces with multi-head setups (8 or 16 heads) for mid-to-large lines.

- Sauce Addition Systems: Auto-pumps meter in oil, tomato sauce, or chili. Built-in stirrers keep mixes uniform for consistent yum.

- Sealing and Sterilization Equipment:

- Auto Sealers: Seal tin, aluminum, or pull-tab cans at 50-300 cans/minute. Vacuum tech extends shelf life to 2-3 years—game-changer!

- Retorts: Vertical or horizontal high-pressure steam units, holding hundreds to thousands of cans. Auto-controls and loggers ensure ISO 22000 compliance. Energy-savers cut steam use by 20%.

- Post-Processing Equipment:

- Coolers: Spray or immersion types for rapid cooldown, staving off secondary microbial growth.

- Labelers and Packers: Auto-labelers add QR codes for tracking; packers box and palletize with robots.

| Equipment Type | Key Function | Example Specs | Capacity Range | Price Range (USD) | Best For |

|---|---|---|---|---|---|

| Hydraulic Unloader | Auto-unload fish | Tilt-style, SUS304 | 1-10 tons/hour | 5,000-15,000 | Large intake ops |

| Washer | High-pressure clean & disinfect | Bubble + ozone | 2-8 tons/hour | 8,000-25,000 | All pre-processing |

| De-Gutter | Auto-remove guts | Adjustable blade speed | 500-2,000 fish/hour | 10,000-30,000 | Mid-small fish handling |

| Quantitative Filler | Precise fill of fish & liquids | Multi-head weighing | 50-200 cans/min | 15,000-50,000 | Core filling stage |

| Sealer | Vacuum seal | Multi-can type support | 65-300 cans/min | 20,000-100,000 | Sealing essentials |

| Retort | High-temp sterilize | Auto-pressure control | Batch 1,000-5,000 cans | 30,000-150,000 | Safety must-have |

| Cooler | Quick temp drop | Spray-style | Matches retort capacity | 10,000-40,000 | Post-sterile necessity |

| Labeler | Auto-tag attachment | QR integration | 100-500 cans/min | 5,000-20,000 | Packaging polish |

These pieces make your line hum beautifully. For tuna canning, filler accuracy ensures uniformity, while retort reliability guards against recalls. Test compatibility before buying—it's like trying on shoes for the perfect fit!

Related Products:Canned Fish Production Line

Five Key Factors for Selecting Equipment

Shopping for fish canning gear isn't about the cheapest deal—it's about smart, balanced choices for max returns. Here are five warm-hearted tips from industry pros, complete with practical advice and pitfalls to dodge. Let's get you equipped like a champ!

- Capacity Matching and Scalability: Assess your daily output first. Small setups (<5,000 cans/day) love semi-auto; bigger ones (>100,000) thrive on full auto. Opt for modular designs for easy upgrades. Pitfall: Underestimating peaks leads to jams; overestimating wastes space. Tip: Factor in busy seasons—adjustable-speed gear can hike efficiency by 30%+.

- Material Quality and Safety Compliance: Go for food-grade stainless that's acid/alkali-proof. Seek CE, ISO, or NSF certs for HACCP alignment. Pitfall: Cheap materials mean contamination or short life (<5 years). Tip: Choose easy-clean designs with no-dead-zone welds. In 2025, EU's tighter heavy metal checks make compliant gear a must.

- Automation Level and Maintenance Ease: Automation saves 50% on labor but ups upfront costs. Pick PLC/touchscreen systems with remote diagnostics. Pitfall: Over-automation complicates training. Tip: Look for suppliers with spare parts stock—AI-integrated monitoring predicts issues, keeping downtime under 1%.

- Budget Management and ROI Calculation: Full lines start at $50,000 (small) to $500,000 (large). Include energy, upkeep, and parts in totals. Pitfall: Low-price picks rack up repair bills. Tip: Use ROI math (gains/investment)—efficient setups pay back in 1-2 years. Leasing eases entry.

- Supplier Reputation and After-Sales Support: Stick with proven makers—check cases and reviews. Pitfall: Sketchy vendors mean poor service and downtime. Tip: Visit factories for customization chats. With global supply hiccups, local or trusted international partners shine.

These factors pave the way for a winning plan. Common slip-ups? Overlooking local regs (like China's GB standards) or energy efficiency, spiking running costs.

Canned Packaging Design Trends: Exciting Directions for 2025

Oh, the thrill of packaging—it's where functionality meets flair! As consumers crave sustainability and eye-candy in 2025, fish canning packaging is evolving big time. Gen Z leads the charge, with 73% favoring recyclables and 78% eyeing local options. This shift impacts your post-processing gear (like labeler compatibility) and boosts market appeal. Let's explore these trends with enthusiasm—they're your ticket to standing out on shelves and social media!

1. Sustainability and Eco-Friendly Materials Innovation

Sustainability is the star! Shift to renewable aluminum cans or bio-based coatings, ditching plastics. Trends: BPA-free liners and easy-recycle labels. Brands like Fishwife rock compostable outer boxes from ocean plastic. Gear tie-in: Pick labelers for eco-tags and add recycle scanners. Perk: Amp up your brand vibe, align with EU Green Deal, and potentially spike sales 20%. Challenge: Higher material costs, but the long-game payoff is huge.

2. Artistic and Vibrant Designs: From Practical to Aesthetic Delight

Packaging as art? Absolutely! 2025 vibes: Bold, saturated colors and dynamic layouts, like Nice Cans' bright blocks emphasizing quality and green creds. Illustrations rule—adorable fish doodles (think Bon Iver collab's salmon-pink boxes) or nostalgic retro logos that tug at heartstrings. Pinterest searches for arty canned fish are up 50%! Gear tip: High-res UV-print labelers for vivid hues. Case: A Portuguese brand's artistic packs boosted sales 30%, fueling "sardine girl summer" buzz.

3. Smart and Interactive Packaging

Get techy! AR labels let scanners reveal fish origins, nutrition, or recipes. 2025: NFC chips for traceability. Reusable designs turn boxes into storage. Line integration: Add QR generators and inspectors. Perk: Boost engagement, loyalty up 15%. It's like giving your cans a personality!

4. Nostalgic and Cultural Fusion

Retro revival: Mimic 19th-century styles with modern twists—clean fonts and cultural motifs (e.g., Mediterranean fish themes). Brands like PierSide weave seafood tales via illustrations. Social fuel: TikTok's "tinned fish" vids hit billions. Tip: Tailor culturally, like bold reds for Asian spicy cans.

5. Miniaturization and Portability Trends

For on-the-go folks, smaller portions (100g singles) with easy-pull tabs and stackable packs. 2025 forecast: Portable canned fish sales up 25%. Gear tweak: Fillers that switch can sizes swiftly.

These trends demand flexible equipment, like quick-change sealers. Team up with designers, test feedback—2025 packaging is all about emotional, green vibes!

Brand Recommendations and Case Studies

Picking a stellar brand is key to success. Here's some friendly picks based on market buzz and real feedback.

- Domestic Brand: Qingdao Hongsheng Yuanlin offers complete fish canning lines with killer customization. Strengths: Tough durability for 24/7 runs, budget-friendly for exporters.

- International Options: Italy's CFT Group for sterilization wizardry; Spain's Dixie Canner for sealing pros. FAO guides point to global case-rich suppliers.

Case Study 1: A Guangdong mid-size cannery swapped to Qingdao Hongsheng Yuanlin's full-auto line, bumping daily output from 50,000 to 80,000 cans, dropping rejects to 0.5%, and saving 10% on sauce via optimized fillers. They added sustainable aluminum cans, supercharging EU exports.

Case Study 2: A Vietnamese exporter grabbed Italian retorts plus AR labels, making waves in North America. Secret sauce: Blending gear with trends for standout edge.

These stories show equipment + trends = big wins. Hit up events like China's International Food Machinery Expo for hands-on compares.

Maintenance Tips and Common FAQs

Keeping your gear humming is pure joy! Daily: Clean retorts (weekly descale), lube belts, calibrate fillers. Yearly overhauls by pros cost about 5% of initial spend.

- Preventive Care: IoT sensors track vibes and temps for fault forecasts. Swap wear parts like seals every 3-6 months.

- Troubleshooting: Fixes for uneven fills (check pumps) or leaky seals (tune vacuums).

FAQs:

- Q: How much for fish canning gear? A: Small full sets $50,000-100,000; large $200,000-500,000, config-dependent.

- Q: Ensuring food safety? A: HACCP-ready gear with regular third-party audits.

- Q: How do packaging trends affect buys? A: Eco-designs need green-material sealers.

- Q: Starter factory tips? A: Begin semi-auto, scale up.

- Q: Implementing 2025 smart packs? A: Add QR printers for AR fun.

Wrapping Up: Invest in Tomorrow, Boost Your Edge

Selecting fish canning line equipment is an exciting strategic move! With this guide's flows, gear, factors, trends, and cases, you're set for an efficient, green powerhouse. In 2025, as packaging goes arty and eco, jump in early for market magic. If you're a gear buyer, chat with experts or hit trade shows. Share your stories in comments—we'll keep the trends flowing! (About 4,200 words, based on 2025 data—reach out for tailored chats.)

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?