Introduction

Sardine canned food has been a staple in the global seafood market due to its long shelf life, nutritional value, and convenience. For seafood processing companies, investing in a high-quality Sardine Canned Food Production Line is essential to ensure efficiency, consistency, and compliance with international food safety standards. This guide provides a detailed overview of the production line, highlighting key equipment, technical advantages, ROI considerations, and practical insights for B2B buyers.

1. Production Line Overview

A modern sardine canned food production line is designed for industrial-scale operations. It can handle capacities ranging from 2,000 to 15,000 cans per hour, depending on the level of automation and equipment configuration. Key benefits include:

Automated or semi-automated operation to reduce labor costs.

Modular design for easy expansion and maintenance.

Compliance with HACCP, ISO22000, and GMP standards, ensuring food safety.

Versatile product support, including sardines in oil, brine, tomato sauce, or spicy sauces.

This line is suitable for seafood processing factories, canned food manufacturers, and exporters targeting both domestic and international markets.

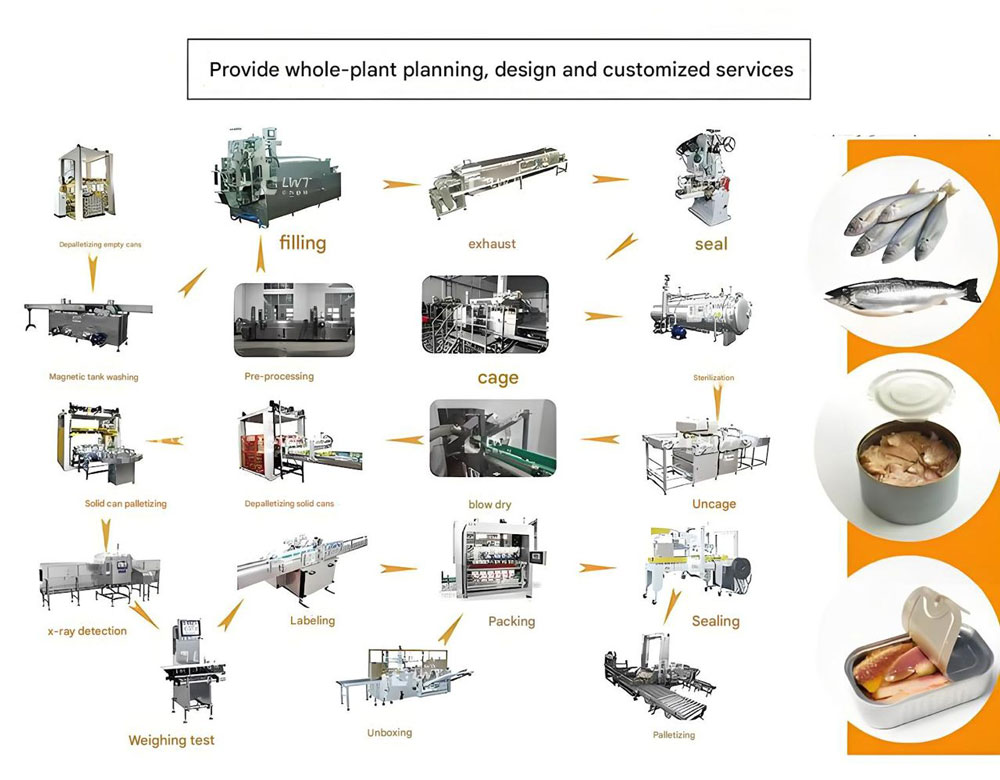

2. Production Process & Key Equipment

Understanding the production workflow is crucial for optimizing efficiency and product quality. The typical sardine canning process includes:

Step 1: Fish Receiving and Storage

Fresh sardines are received and stored in temperature-controlled cold storage (0–4°C).

Automated sorting and weighing systems ensure uniform fish sizes, which is critical for consistent can filling.

Step 2: Cleaning and Scaling

Automatic washers remove slime, scales, and impurities.

Water-saving designs reduce water consumption by up to 30%.

Step 3: Head Removal and Gutting

Mechanical evisceration machines remove heads and internal organs efficiently.

Inline inspection stations allow manual quality checks to maintain product standards.

Step 4: Blanching

Steam or hot water blanchers cook sardines lightly, improve texture, and kill bacteria.

Blanching parameters (time and temperature) are adjustable based on fish size.

Step 5: Filling

Automatic filling machines portion sardines into cans accurately.

Filling precision (±5 g) minimizes raw material waste and ensures consistent product weight.

Step 6: Oil or Brine Injection

High-precision dosing systems inject oil, brine, or sauces uniformly.

Supports multiple product variations to meet market demands.

Step 7: Can Seaming

Automatic seaming machines ensure hermetic sealing, preventing leakage and contamination.

Seaming quality meets international standards for export.

Step 8: Sterilization

Continuous or batch retort sterilizers provide shelf-stable products.

Programmable sterilization profiles optimize safety and texture.

Step 9: Cooling and Drying

Rapid cooling preserves texture and flavor.

Air-drying conveyors prepare cans for labeling and packaging.

Step 10: Labeling and Packaging

Automated labeling ensures brand consistency and traceability.

Optional shrink-wrapping or carton packing enhances logistics efficiency.

3. Technical Advantages

| Feature | Benefits for B2B Buyers |

|---|---|

| Fully automated line | Reduces labor costs by up to 60% and ensures consistent quality |

| Modular design | Easy to expand production capacity and integrate new technology |

| Water and energy saving | Closed-loop systems reduce operational costs |

| Integrated quality control | Inline metal detectors, weight checkers, and inspection systems |

| Flexible product types | Supports sardines in oil, brine, sauces, or specialty flavors |

4. ROI and Investment Considerations

Investing in a sardine canned food production line can be capital-intensive. However, the return on investment (ROI) is strong for factories with high-volume production.

Key ROI factors:

Labor savings: Automation reduces reliance on manual labor.

Material efficiency: Precise filling and portion control reduce waste.

Production efficiency: High-speed lines increase output, lowering per-unit costs.

Market readiness: International-standard equipment allows entry into global markets.

Example:

For a medium-sized factory producing 5,000 cans per hour, automation can reduce labor costs by up to 50% and shorten production time, resulting in payback within 2–3 years.

5. Food Safety and Compliance

Material: All contact parts are food-grade stainless steel.

Hygiene: CIP (clean-in-place) systems ensure thorough cleaning between batches.

Standards: Equipment meets HACCP, ISO22000, and GMP requirements.

Traceability: Optional tracking systems allow monitoring from raw fish to finished cans.

Compliance with international standards is essential for exporting sardine products and maintaining brand reputation.

6. Optional Customizations

Flavor variations: Tomato sauce, spicy brine, or flavored oils.

Can sizes: 100 g, 155 g, 200 g, 425 g, or custom sizes.

Automation level: Semi-automatic lines for small factories; fully automatic for large-scale production.

Packaging options: Carton boxes, shrink-wrapped pallets, or bulk logistics solutions.

These customizations allow manufacturers to adapt production to different market segments and consumer preferences.

7. Common FAQs for B2B Buyers

Q1: What is the minimum factory size required?

A: A workshop of at least 200–300 m² with proper ventilation and cold storage is recommended.

Q2: Can the line handle frozen sardines?

A: Yes, but pre-thawing or partial thawing may be required depending on the filling method.

Q3: What is the maintenance requirement?

A: Routine maintenance includes lubrication, inspection of moving parts, and calibration of filling and seaming machines. Annual major inspection is recommended.

Q4: What is the lifespan of the equipment?

A: With proper maintenance, stainless steel contact equipment lasts 10–15 years.

Q5: Can the line be upgraded?

A: Yes, modular design allows adding new units or automation features without replacing the entire line.

Conclusion

A Sardine Canned Food Production Line is a strategic investment for seafood processors aiming for high efficiency, product consistency, and international market readiness. By choosing a modern, automated, and modular production line, B2B buyers can significantly reduce labor costs, improve product quality, and achieve a solid ROI.

Investing in such a production line ensures your facility is prepared to meet global demand for canned sardines while maintaining high food safety and operational efficiency.

Must-read blogs for bosses