Best Ice Maker Factory In China - Chinese Manufacturer, Factory, Supplier

When searching for the best ice maker factory in China, discerning buyers prioritize more than just price. They seek reliability, precision engineering, and a proven track record of excellence in the refrigeration industry. China’s manufacturing sector is home to some of the world’s most advanced facilities, and the best ice maker factory in China stands out through its commitment to innovation, quality control, and customer satisfaction.

These factories specialize in producing a wide spectrum of ice-making solutions, from compact under-counter units designed for cafes and bars to high-capacity industrial machines tailored for fisheries, logistics, and medical applications. What sets the best ice maker factory in China apart is not only the breadth of its product line but also the technological sophistication embedded in each unit. Intelligent microcomputer controls, energy-efficient compressors, and corrosion-resistant materials are standard features, ensuring machines that operate with precision and longevity.

Attention to detail is paramount. Every phase of production — from raw material procurement to rigorous performance testing — is governed by strict quality management systems. International certifications such as CE, ETL, and ISO reflect the factory’s unwavering adherence to global standards. This meticulous approach fortifies the best ice maker factory in China as a trusted partner in global supply chains, delivering equipment that meets the diverse needs of commercial and industrial clients.

Beyond manufacturing prowess, these factories provide robust OEM and ODM services. Customization is key in today’s competitive marketplace, and the best ice maker factory in China offers tailored solutions that align with specific branding, technical specifications, and market demands. This flexibility, combined with efficient production lead times and responsive technical support, creates tangible value for distributors and end-users alike.

Moreover, sustainability is an increasingly important consideration. Leading Chinese manufacturers are integrating eco-friendly refrigerants, energy-saving technologies, and recyclable materials into their product designs. This forward-thinking approach not only reduces environmental impact but also enhances operational efficiency for the end user.

Choosing the best ice maker factory in China is a strategic decision. It’s a gateway to dependable quality, technological innovation, and long-term business growth. These factories exemplify the highest standards of Chinese manufacturing, delivering solutions that keep pace with the evolving needs of industries worldwide.

AF Series Flake Pellet Ice Machine

AF Series Flake Pellet Ice Machine SC Series Bullet Ice Maker

SC Series Bullet Ice Maker SF Series Snowflake Ice Machine

SF Series Snowflake Ice Machine AP Series Flake Ice Machine

AP Series Flake Ice Machine SY-168 / SY-158 Commercial Ice Shaver Machine

SY-168 / SY-158 Commercial Ice Shaver Machine AM Series Crescent Ice Maker

AM Series Crescent Ice Maker SD Square Ice Series Upright Ice Makers

SD Square Ice Series Upright Ice Makers Household Meat Grinder

Household Meat Grinder Automatic Meatball Making Machine

Automatic Meatball Making Machine French Fries Cutting Machine

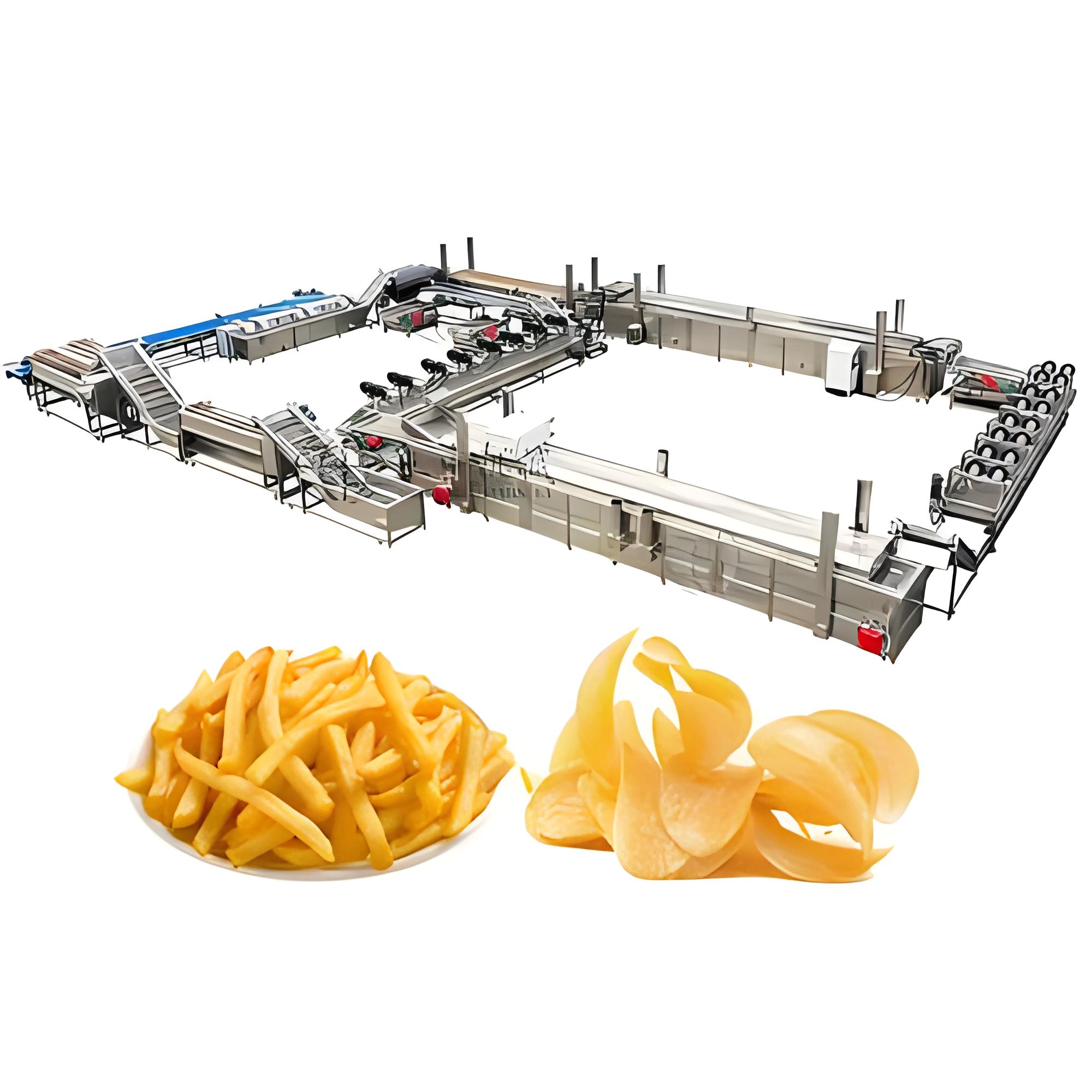

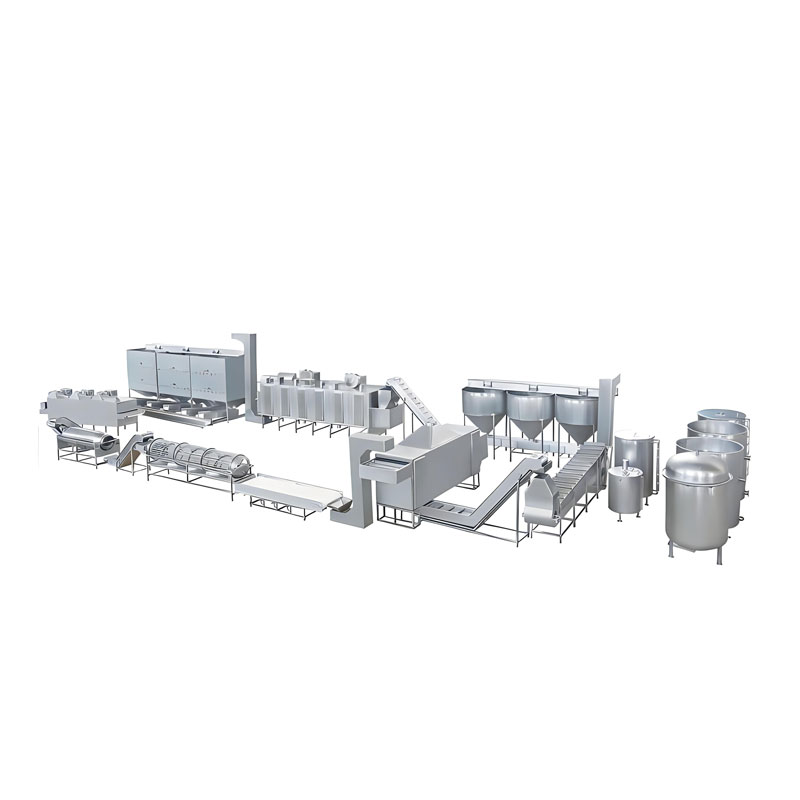

French Fries Cutting Machine French Fries Production Line

French Fries Production Line Microwave Pigskin Puffing Machine

Microwave Pigskin Puffing Machine Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Kimchi Production Line

Kimchi Production Line Gummy Candy Production Line

Gummy Candy Production Line