Best Snacks Food Frozen Dumpling Packing Machine Factory - Chinese Manufacturer, Factory, Supplier

A best snacks food frozen dumpling packing machine factory plays a vital role in today’s frozen food industry by providing innovative equipment that combines speed, precision, and food safety. With the global demand for frozen snacks rising rapidly, these factories supply advanced packing machines that streamline operations and protect product quality from the production floor to the consumer’s table.

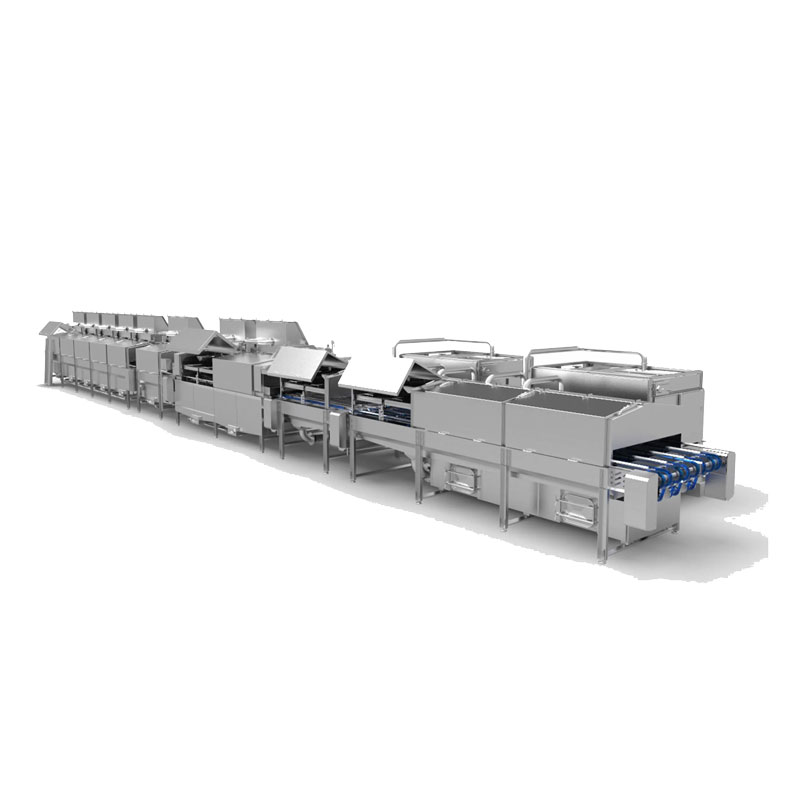

Modern packing machines from such factories are engineered to handle delicate frozen dumplings without breakage, ensuring each piece maintains its shape and texture. Intelligent weighing systems, high-speed conveyors, and automated sealing units work together to deliver consistent results. The packaging process not only secures freshness but also enhances shelf appeal with tight seals, clear labeling, and versatile format options.

Unlike conventional systems, equipment from a frozen dumpling packing machine factory is designed for adaptability. From small retail bags to larger bulk cartons for foodservice buyers, the machines can be adjusted quickly to accommodate different packaging needs. Many models also support eco-friendly films and advanced preservation technologies, extending shelf life while meeting sustainability targets.

Durability and hygiene are central to the design. Factories typically construct machines from heavy-duty stainless steel with easy-clean surfaces and CIP (clean-in-place) functions. This reduces downtime, ensures compliance with HACCP and ISO standards, and provides peace of mind for producers serving international markets.

What distinguishes the best snacks food frozen dumpling packing machine factory is not just the hardware but the service behind it. From plant layout planning to installation, operator training, and after-sales support, these factories deliver turnkey solutions that help food producers optimize performance and minimize operational costs.

For companies in the frozen snack sector, investing in machines from a reliable factory is a strategic move. It guarantees faster packing cycles, reduced waste, and packaging that preserves both flavor and presentation—critical factors in winning consumer trust and building a competitive edge.

Automatic Dumpling Making Machine

Automatic Dumpling Making Machine Tomato Sauce Machine

Tomato Sauce Machine Cooking Drying Oven

Cooking Drying Oven Leisure Baking Snack Packaging Machine

Leisure Baking Snack Packaging Machine Fish Food Processing Line

Fish Food Processing Line Gizzard Defatter

Gizzard Defatter Biscuit Line

Biscuit Line Shrimp Processing Line

Shrimp Processing Line Double-Door Sterilizer

Double-Door Sterilizer