Bowl Meat Cutter Machine Factory - Chinese Manufacturer, Factory, Supplier

At our Bowl Meat Cutter Machine Factory, we don’t just build machines — we engineer precision tools that transform raw meat into perfectly processed, high-value products. Designed for demanding meat processors, deli product manufacturers, and industrial kitchens, our bowl cutters enable operators to achieve the fine texture, uniform blending, and temperature control essential for premium sausages, meat emulsions, pâtés, and specialty protein blends.

What sets our equipment apart is the synchronized blade-and-bowl system. Each knife arc is calculated to maximize contact with the product while minimizing friction, keeping mixture temperatures stable to protect protein structure and moisture content. This technical detail ensures that even at high RPMs, your product retains its flavor integrity and optimal mouthfeel.

Our machines are designed with operator-centric features: an angled loading position for easier raw material input, programmable cutting cycles for recipe consistency, and a quick-release blade assembly for tool-free maintenance. The bowl geometry is engineered to create a natural product flow, ensuring every gram of meat is evenly processed without manual intervention.

For processors scaling production, we offer capacity ranges from 20 liters for pilot runs to 750 liters for industrial-scale output, with optional vacuum cutting technology to remove air pockets and enhance product density. Each unit can be integrated into your existing workflow — whether feeding directly into a stuffer, mixer, or automated packaging line.

Every bowl cutter leaving our factory is built from polished SS304 or SS316 stainless steel, with fully sealed housings that allow high-pressure washdowns without compromising longevity. Our commitment doesn’t end at delivery — we provide on-site commissioning, staff training, preventive maintenance plans, and rapid spare parts dispatch to keep your production line running at peak efficiency.

If your goal is to elevate meat processing from functional to exceptional, our bowl meat cutter solutions are engineered to help you achieve it — with consistency, scalability, and uncompromising quality at every batch.

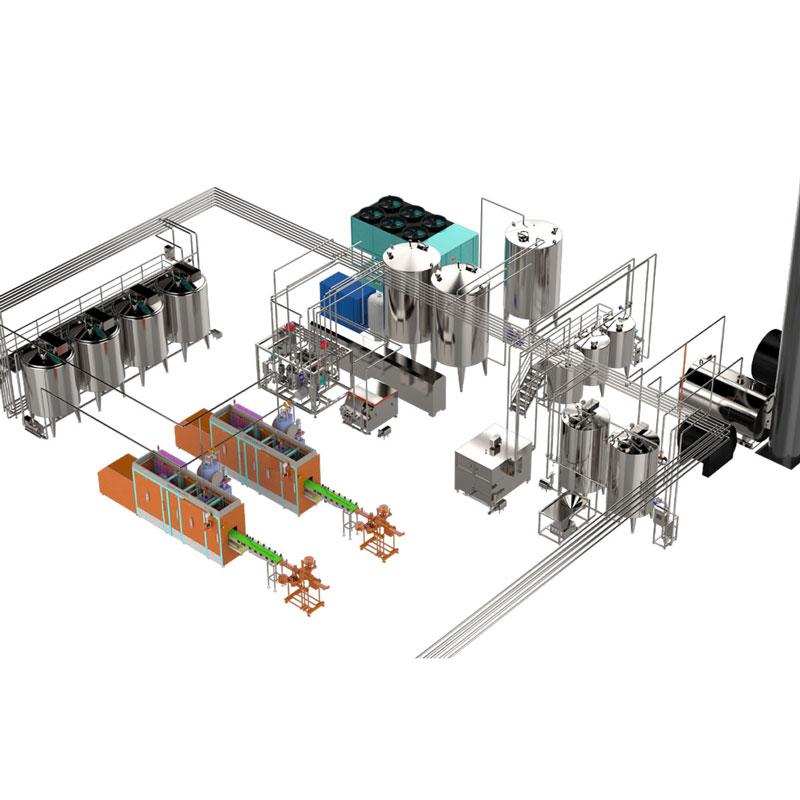

Meat Canned Food Production Line

Meat Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Fully Automatic Meat Can Production Lines

Fully Automatic Meat Can Production Lines Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Automatic Sausage Peeling Machine

Automatic Sausage Peeling Machine Gas Shawarma Machine

Gas Shawarma Machine Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler Yogurt Production Line

Yogurt Production Line Meat Stuffer Machine

Meat Stuffer Machine French Fries Frying Machine

French Fries Frying Machine Sea Fish Canning Production Line

Sea Fish Canning Production Line