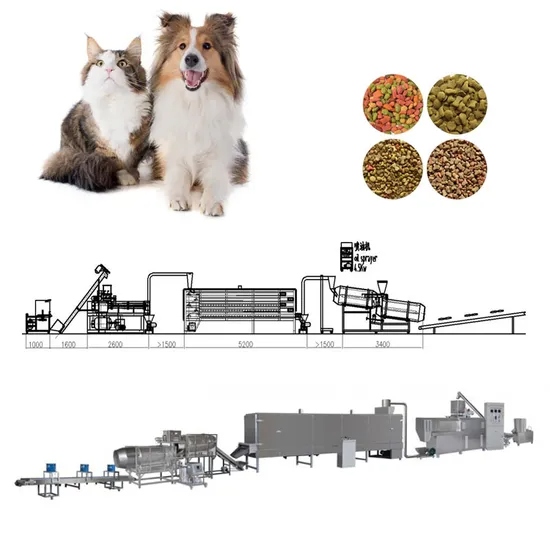

Pet Food Machinery Manufacturers - Chinese Manufacturer, Factory, Supplier

Leading pet food machinery manufacturers in China, such as Qingdao Hongshengyuanlin Co., Ltd., specialize in providing advanced, automated equipment for the production of high-quality pet food. Their machinery caters to a variety of pet food types, including dry kibble, semi-moist products, wet canned food, and snacks, offering turnkey solutions for both small and large-scale production facilities.

Modern Pet Food Production Lines require precision, consistency, and strict hygiene standards to meet global regulations such as HACCP, ISO22000, and CE certification. Manufacturers provide complete systems, including mixers, extruders, dryers, coating machines, cooling conveyors, and packaging units. Each piece of equipment is constructed with food-grade stainless steel, designed for durability, easy cleaning, and corrosion resistance, ensuring product safety and quality.

Automation is a central feature of contemporary pet food production. Integrated PLC control systems, touchscreen interfaces, and data monitoring solutions allow operators to control feed ratios, moisture content, extrusion temperature, and drying cycles precisely. This level of automation reduces labor costs, improves consistency, and enables high-volume production with minimal human intervention.

Top pet food machinery manufacturers also provide custom turnkey solutions, including factory layout planning, equipment customization, installation, commissioning, and staff training. Lines can be adapted for various animal species and product types, ensuring flexibility for clients targeting dogs, cats, fish, or exotic pets. Optional modules, such as flavor coating, vacuum packaging, and labeling systems, further enhance product quality and market appeal.

Chinese suppliers have become increasingly competitive globally due to their cost-effective engineering, export experience, and comprehensive after-sales support. They deliver projects across Southeast Asia, the Middle East, Europe, Africa, and South America, helping pet food producers modernize their facilities, improve production efficiency, and achieve consistent product quality.

By combining technological innovation, customized engineering, and global project experience, these manufacturers enable pet food processors to scale operations, maintain strict hygiene, and enhance profitability. Partnering with a reliable pet food machinery manufacturer ensures long-term success in the competitive pet food industry.

Types of Pet Food Machinery & Applications

| Category | Main Equipment | Core Function | Applications |

|---|---|---|---|

| Mixing & Pre-conditioning | Ribbon mixers, paddle mixers, pre-conditioners | Uniform blending of raw materials, heat/moisture conditioning | Dry kibble, semi-moist food, snacks |

| Extrusion & Shaping | Single-screw and twin-screw extruders, shaping dies | Cooking, shaping, and texturizing pet food | Dog kibble, cat food, fish feed, treats |

| Drying & Cooling Systems | Conveyor dryers, belt coolers, rotary coolers | Reduce moisture content, stabilize shape, cool products | Dry and semi-moist pet food |

| Coating & Flavoring Machines | Enrobers, spray coaters, vacuum coaters | Apply fats, vitamins, flavors, and functional additives | Dry kibble, snacks, supplements |

| Wet / Canned Food Lines | Mixers, fillers, can seamers, sterilizers | Prepare, fill, seal, and sterilize wet pet food | Canned dog, cat, and exotic animal food |

| Snack & Treat Production | Dough mixers, extruders, cutting machines, ovens | Produce baked or extruded treats | Biscuits, jerky, chew sticks, soft snacks |

| Packaging & Labeling | Vacuum packers, tray sealers, bagging machines, labeling units | Preserve products, ensure traceability, retail-ready packaging | Bags, cans, pouches, boxes |

| Quality Control & Inspection | Metal detectors, vision sorting, weight checkers | Ensure safety, uniformity, and compliance | HACCP and export-grade production lines |

| Auxiliary & Support Systems | Conveyors, storage bins, sifters, water pumps | Material transfer, storage, and process support | Integrated production lines for dry, wet, and snack pet foods |

| Automation & Monitoring | PLC systems, touchscreen controls, data monitoring software | Centralized operation, real-time adjustments, process efficiency | Complete automated pet food production lines |

Meat Canned Food Production Line

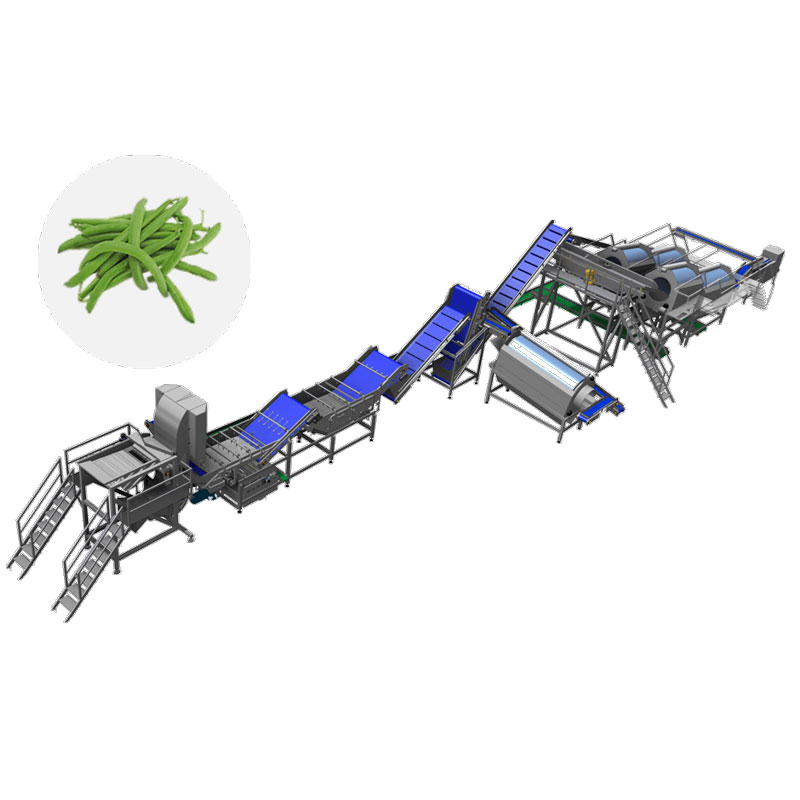

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Dry Pet Food Production Line

Dry Pet Food Production Line Canned Food Filling And Sealing Line

Canned Food Filling And Sealing Line Spinach Canned Canned Food Canning Production Line

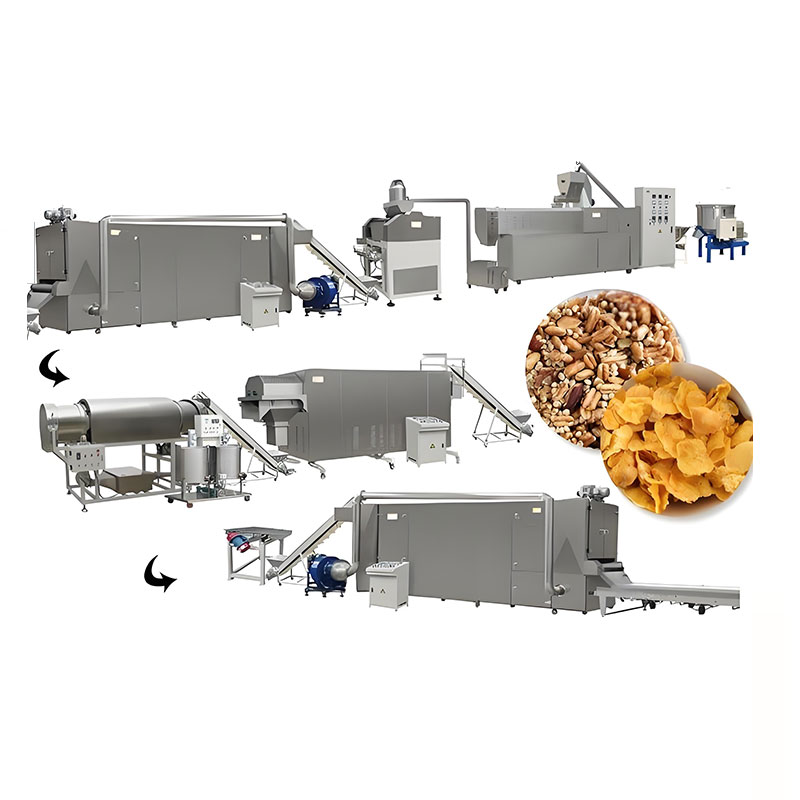

Spinach Canned Canned Food Canning Production Line Corn Flakes Food Production Line

Corn Flakes Food Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Screw Potato Peeling Washing Machine

Screw Potato Peeling Washing Machine Pork Skin Removing Machine

Pork Skin Removing Machine Commercial Pasta Extruder

Commercial Pasta Extruder Mango Juice Processing Production Line

Mango Juice Processing Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Electric Cooked Meat Slicer

Electric Cooked Meat Slicer