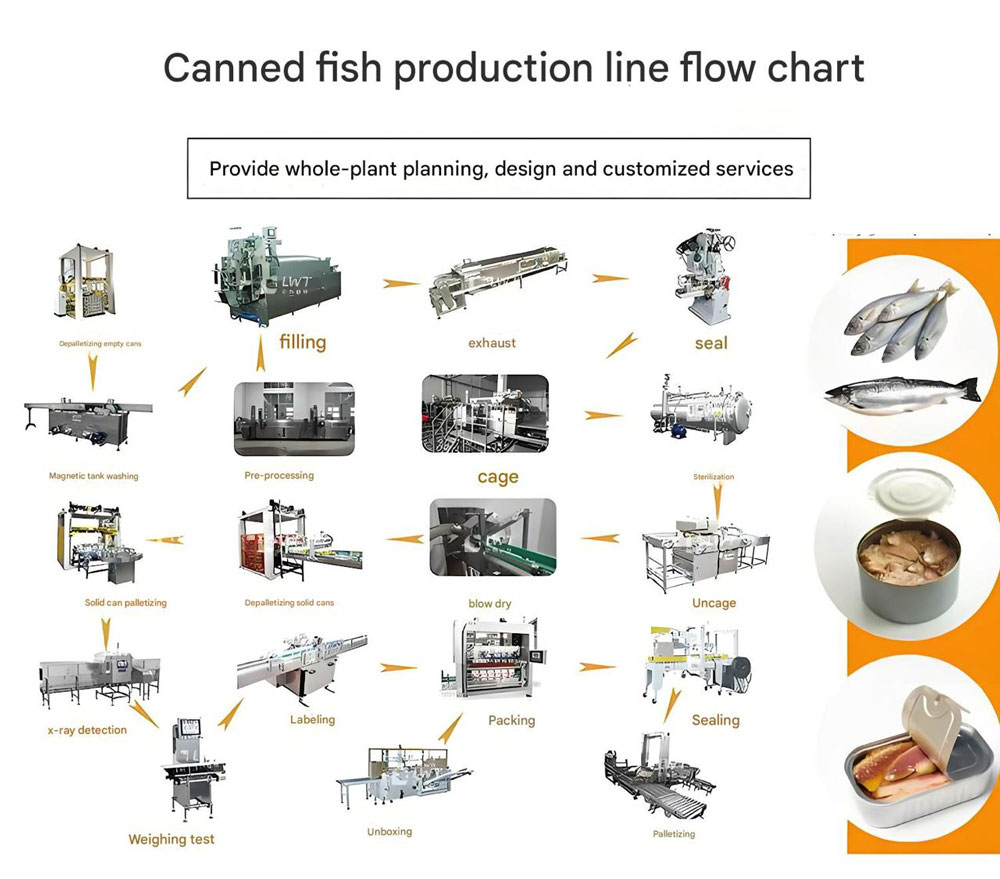

How Canning Production Line Works

In the global food industry, canning production lines are the backbone of modern food preservation. From sardines and tuna to fruits, vegetables, soups, and sauces, canning allows products to be stored safely for months or even years—without losing flavor, texture, or nutrition.

Whether you are a food manufacturer expanding production capacity or an investor exploring automated food packaging systems, understanding how a canning production line works is essential. This guide explains every step in the process, the equipment involved, and how technology has transformed the efficiency, safety, and sustainability of canning operations.

1. What Is a Canning Production Line?

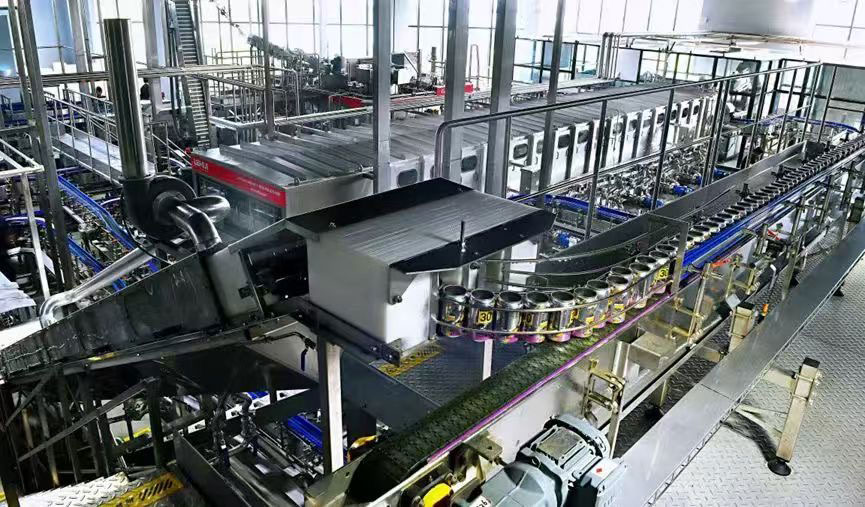

A canning production line is a fully integrated system of machines designed to clean, fill, seal, sterilize, and label food or beverages in metal, glass, or aluminum cans. It combines mechanical automation, food safety technology, and precision engineering to produce high-quality, shelf-stable products.

Modern canning lines can handle from 1,000 to over 100,000 cans per hour, depending on scale, automation level, and product type.

Main Applications:

Fish canning: Tuna, sardines, mackerel, salmon, anchovies

Meat canning: Chicken, beef, luncheon meat

Fruit and vegetable canning: Peaches, corn, mushrooms, beans

Sauce and soup canning: Tomato paste, chili sauce, soups

Beverage canning: Juices, coffee, milk, soft drinks

2. Overview of the Canning Process

The canning process involves six core stages:

Raw Material Preparation

Filling

Sealing

Sterilization (Retorting)

Cooling and Drying

Labeling and Packaging

Let’s explore each step in detail.

3. Step-by-Step: How the Canning Line Works

Step 1: Raw Material Preparation

The process begins with sorting, cleaning, cutting, and pre-cooking the raw materials.

Sorting & Grading:

Ensures uniform size and quality for consistency in filling. Optical sorting machines or manual inspection lines are used.Washing:

High-pressure washing systems remove dirt, scales, or residues.Cutting or Slicing:

Automatic cutting machines prepare the material for filling—especially important for fish, fruits, and vegetables.Pre-cooking or Blanching:

Some products (like fish or vegetables) are pre-cooked to remove air, deactivate enzymes, and improve texture before canning.

Step 2: Filling

After preparation, food is transferred to the automatic filling machine.

Volumetric Fillers: Measure and fill exact portions of solids or liquids.

Piston Fillers: Ideal for sauces, soups, or thick liquids.

Multi-head Weigh Fillers: Used for meat, vegetables, or seafood.

Automation ensures each can contains the same quantity, which is critical for both cost control and product consistency.

Step 3: Sealing (Can Seaming)

Once filled, cans are sealed with lids using a high-speed seaming machine.

Modern seamers ensure airtight closure through a double or triple seam that prevents contamination and leakage.

For different can materials—tinplate, aluminum, or composite—machine settings can be adjusted for precision sealing.

Step 4: Sterilization (Retorting)

Sterilization is the most critical step in canning. It destroys microorganisms that could cause spoilage or foodborne illness.

This is typically done in retort sterilizers (autoclaves) using high-temperature steam or water at pressures above 121°C (250°F).

Static Retorts: Ideal for solid foods like meat or fish.

Rotary Retorts: Used for liquid or semi-liquid products to ensure uniform heating.

The sterilization parameters—temperature, pressure, and duration—are tailored to each product type to preserve quality and flavor while ensuring safety.

Step 5: Cooling and Drying

After sterilization, cans are rapidly cooled using water spray or immersion systems to prevent overcooking and preserve texture.

Then, air-drying systems remove moisture from the can surface to prevent rust or label issues.

Step 6: Labeling and Packaging

The final step involves labeling, coding, and packaging for shipment.

Labeling Machines: Apply paper, film, or shrink labels.

Inkjet Coders: Print production dates, batch codes, and traceability information.

Cartoning Machines: Pack cans into boxes or pallets for transport.

4. Key Equipment in a Canning Production Line

| Stage | Equipment | Function |

|---|---|---|

| Raw Material Preparation | Washer, Cutter, Blancher | Cleaning and preparing food |

| Filling | Automatic Filler | Precise dosing of solids/liquids |

| Sealing | Seaming Machine | Airtight can closure |

| Sterilization | Retort Sterilizer | High-temp sterilization |

| Cooling | Cooling Conveyor | Temperature reduction |

| Labeling & Packaging | Labeler, Coder, Cartoner | Final packaging and traceability |

5. Automation and Smart Control Systems

Modern canning production lines integrate PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) for real-time monitoring and control.

Advantages include:

Automatic temperature and pressure control

Data tracking for food safety

Remote maintenance and diagnostics

Reduced labor dependency

Some advanced lines use AI-driven inspection cameras to detect dents, leaks, or sealing defects, ensuring 100% quality assurance.

6. Energy Efficiency and Sustainability

Sustainability is now a core focus in the canning industry. Manufacturers adopt technologies that reduce energy and water consumption while maintaining output.

Heat Recovery Systems: Reuse waste heat from sterilization.

Water Recycling Units: Filter and reuse cooling water.

Lightweight Can Design: Reduces material cost and shipping weight.

Solar or Biomass Energy Integration: Minimizes carbon footprint.

7. Quality Control and Food Safety

Canning operations must comply with strict international food safety standards such as:

HACCP (Hazard Analysis and Critical Control Points)

ISO 22000: Food Safety Management System

FDA and EU Regulations

Each production step—especially filling, seaming, and sterilization—is monitored under these systems to ensure consumer safety.

8. Production Capacity: How Many Cans per Day?

Production capacity depends on equipment scale and automation level.

| Line Type | Cans per Minute | Cans per Day (8-hour shift) |

|---|---|---|

| Small-Scale (Manual/Semi-auto) | 30–100 | 14,000–48,000 |

| Medium-Scale (Automatic) | 200–500 | 96,000–240,000 |

| Industrial (Fully Automatic) | 800–2,000 | 384,000–960,000 |

High-speed industrial lines—used for tuna, sardines, or beans—can exceed 1 million cans per day with multiple retort systems running simultaneously.

9. Maintenance and Operation Best Practices

To ensure long-term performance:

Regular calibration of fillers and seamers.

Routine inspection of retort valves and sensors.

Lubrication and cleaning schedules to prevent corrosion.

Operator training for safety and troubleshooting.

Many modern systems now feature predictive maintenance modules that alert operators before a machine fault occurs.

10. Choosing the Right Canning Line Manufacturer

When investing in a canning production line, consider:

Experience in your specific product type (e.g., fish, fruit, sauces)

Automation and customization capabilities

After-sales service and spare parts availability

Compliance with international standards

References or case studies from similar markets

Top Chinese manufacturers such as Qingdao Hongshengyuanlin Co., Ltd., Zhucheng Zhongyu Machinery, and Shanghai Leadworld are gaining global recognition for providing turnkey canning line solutions tailored to export-oriented factories.

11. Industry Trends and Future Outlook

The canning industry is evolving with several key trends:

Smart factories with IoT-based quality monitoring.

Flexible packaging lines that handle multiple can sizes.

Sustainable materials replacing traditional tinplate.

Integration with ERP systems for supply chain tracking.

As global demand for ready-to-eat and shelf-stable foods increases, automation and energy-efficient designs will continue to dominate the future of canning production.

12. Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of a canning line?

A high-quality line can last 10–15 years, depending on maintenance and operating conditions.

Q2: Can one line produce different products?

Yes. With modular designs and adjustable parameters, you can switch between fish, vegetables, or sauces with minor changeovers.

Q3: How much does a canning production line cost?

Prices range from $30,000 for small-scale semi-automatic systems to over $1 million for large industrial turnkey lines.

Q4: What is the sterilization time for canned fish?

Typically 40–60 minutes at 121°C, depending on can size and product density.

Q5: How to ensure can seam integrity?

Use seam inspection gauges and regularly test seam tightness according to international standards.

Conclusion

A canning production line represents the perfect integration of food science, mechanical engineering, and automation technology. It ensures that foods remain safe, nutritious, and flavorful long after production—helping manufacturers expand markets across continents.

Whether you’re producing tuna in Thailand, tomato paste in China, or fruit cocktails in South America, investing in a modern, efficient canning line is essential for achieving consistency, compliance, and profitability in today’s competitive food industry.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?