Product Overview

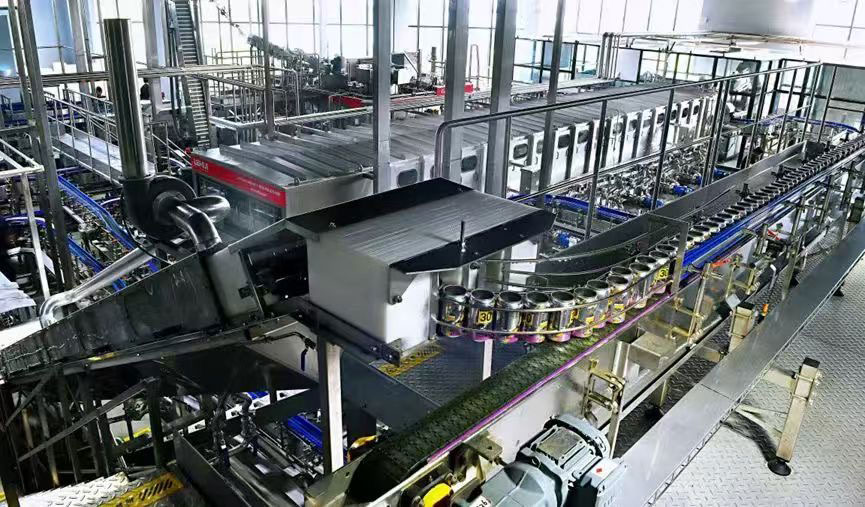

The Canned Fish Production Line is a fully automated solution designed for the efficient processing and packaging of sardines, tuna, mackerel, and other fish species.

This production line integrates all major processes — from raw fish cleaning and cutting to filling, seaming, sterilization, and packaging — ensuring high productivity, consistent quality, and strict compliance with international food safety standards.

With advanced automation control, stainless-steel sanitary design, and flexible configuration options, this production line helps seafood processors reduce labor costs, minimize waste, and maximize return on investment.

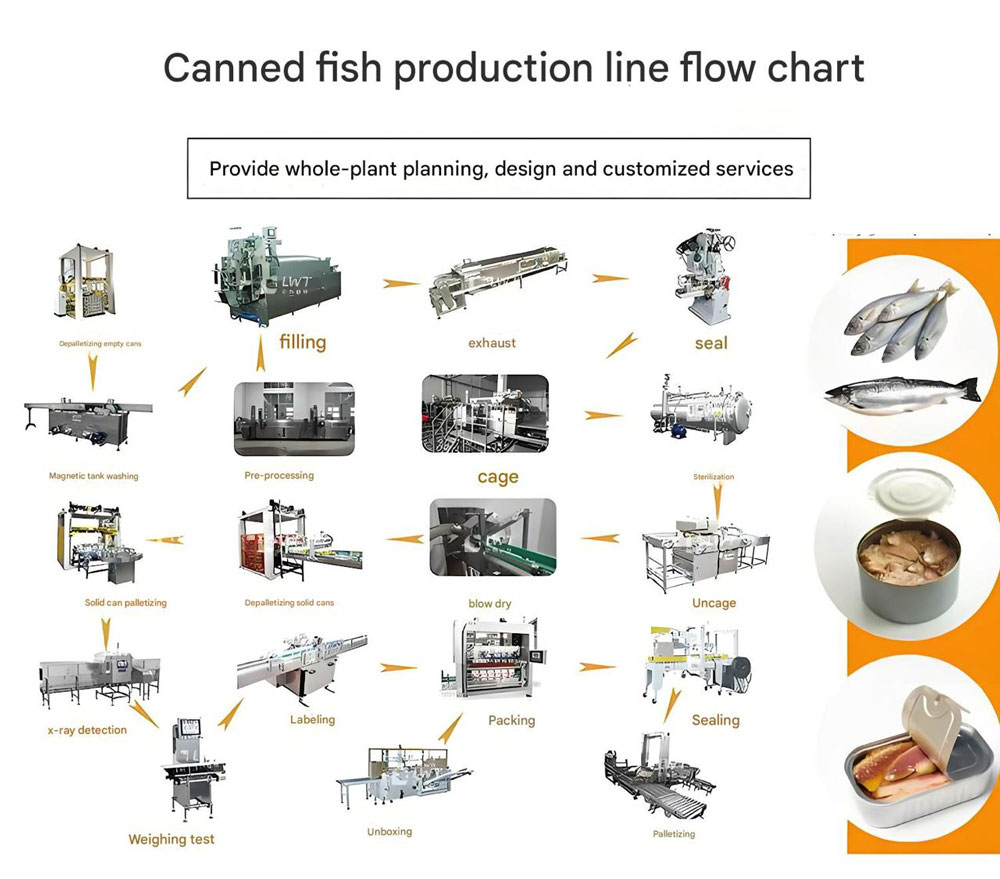

Processing Flow

Raw Fish → Sorting → Cutting/Filleting → Cooking/Steaming → Filling → Sauce Adding → Seaming → Sterilization → Cooling → Labeling → Packaging

Each section of the production line is designed for precision, hygiene, and operational efficiency:

Fish Cleaning & Sorting: Automatically removes impurities and classifies fish by size for consistent processing.

Cutting & Filleting Machine: Accurate trimming minimizes meat loss and ensures uniform portioning.

Cooking/Steaming Unit: Controlled temperature ensures even heating while retaining natural flavor and texture.

Filling Machine: Precisely fills fish meat and brine or sauce, improving consistency across each can.

Seaming Machine: High-speed can seamer guarantees airtight sealing to prevent leakage.

Retort Sterilizer: High-temperature and high-pressure sterilization ensures long shelf life and food safety.

Cooling System: Rapid cooling after sterilization prevents overcooking and maintains product quality.

Labeling & Packaging: Supports automatic labeling, coding, and secondary packaging for various can sizes.

Technical Highlights

| Feature | Description |

|---|---|

| Automation Control | PLC + HMI intelligent system for real-time monitoring and easy operation. |

| Hygienic Design | Full 304/316 stainless steel structure, corrosion-resistant and easy to clean. |

| Energy Efficiency | Steam recycling and optimized heating system reduce energy consumption by up to 15%. |

| Flexible Configuration | Compatible with round cans, easy-open cans, and different can diameters. |

| Safety Compliance | Fully meets CE, ISO, HACCP, and FDA international food safety standards. |

Each component of the line is modular, allowing for flexible layout and future capacity upgrades according to factory requirements.

Technical Parameters

| Model | Capacity (Cans/hour) | Power | Steam Pressure | Can Diameter | Labor Required |

|---|---|---|---|---|---|

| YL-CF-2000 | 2,000 | 15 kW | 0.6 MPa | 65–99 mm | 4–5 |

| YL-CF-4000 | 4,000 | 25 kW | 0.8 MPa | 65–99 mm | 6–8 |

| YL-CF-8000 | 8,000 | 45 kW | 0.8 MPa | 65–99 mm | 8–10 |

Customized configurations (up to 20,000 cans/hour) are available upon request.

Return on Investment (ROI)

Labor Reduction: Automation reduces manual labor by 40–60%.

Higher Yield: Consistent filling and sealing increase the finished product rate by over 10%.

Energy Savings: Optimized steam and cooling circulation lower operating costs.

Investment Payback: Average payback period within 12–18 months, depending on production scale.

The entire line is designed to help seafood processors achieve stable, large-scale production while maintaining profitability and product quality.

Applicable Products & Fish Types

Suitable for sardines, tuna, mackerel, anchovy, salmon, and other fish species.

End Products:

Canned fish in oil, tomato sauce, or brine

Ready-to-eat fish products

Export-standard canned seafood for retail and foodservice markets

Applications:

Seafood processing plants

Canned food factories

OEM/ODM manufacturers for international brands

Customized Turnkey Solutions

Our engineering team provides one-stop factory layout design and turnkey project solutions, including:

Complete layout drawing based on your workshop space

Integration of auxiliary equipment (metal detector, X-ray inspection, automatic weighing system)

On-site installation, commissioning, and operator training

Process optimization according to fish type and recipe formulation

Each project is tailored to meet the client’s capacity, automation level, and local regulatory requirements.

Project Cases

| Country | Product Type | Capacity | Year |

|---|---|---|---|

| Indonesia | Sardine in Tomato Sauce | 10,000 CPH | 2024 |

| Morocco | Tuna in Oil | 8,000 CPH | 2023 |

| Spain | Mackerel Can Line | 6,000 CPH | 2023 |

Trusted by seafood processors in over 40 countries, our equipment delivers consistent performance and long-term reliability in both tropical and temperate production environments.

Must-read blogs for bosses