Automated Pizza Production Line - Chinese Manufacturer, Factory, Supplier

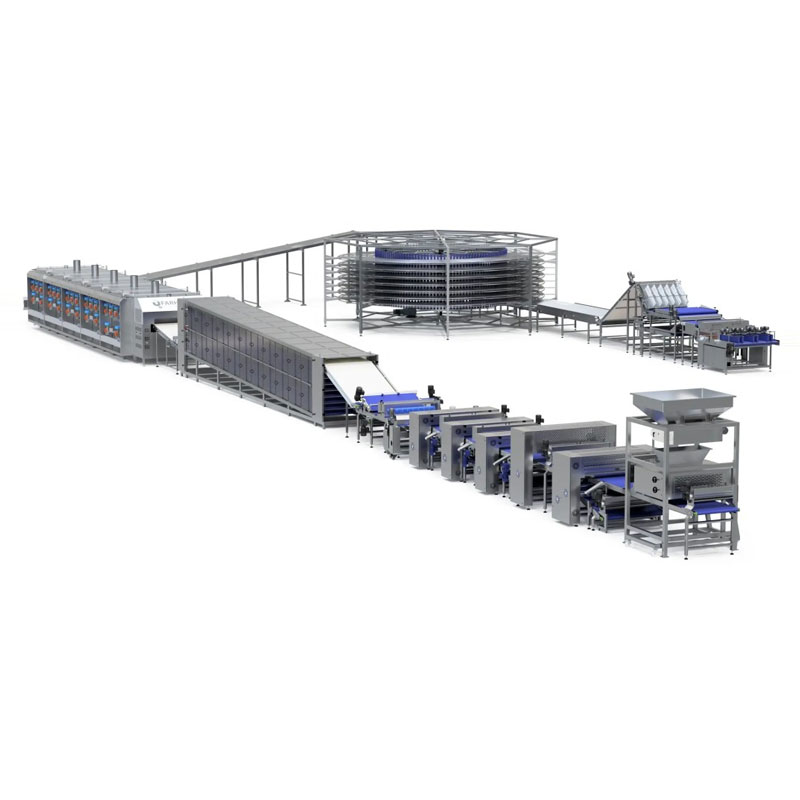

The Automated Pizza Production Line represents the pinnacle of innovation in the modern food processing industry. Designed to optimize consistency, hygiene, and output, this specialized equipment transforms the traditionally labor-intensive process of pizza manufacturing into a seamless, high-efficiency operation. From dough preparation through to final packaging, each stage is meticulously engineered to deliver uniform, high-quality results on a continuous basis.

A typical Automated Pizza Production Line begins with precision dough mixing and sheeting, ensuring uniform thickness and perfect roundness for every base. Automated sauce spreaders and topping applicators guarantee accurate distribution, whether dealing with cheese, meats, or vegetables. This not only minimizes ingredient waste but also ensures aesthetic consistency — a critical factor for consumer satisfaction and brand reputation.

Baking within the Automated Pizza Production Line is controlled through high-performance tunnel ovens that maintain exact temperatures and conveyor speeds. This guarantees every pizza achieves the desired balance of a golden, crispy crust with evenly melted toppings. Post-baking, rapid cooling or flash freezing technology locks in freshness, texture, and flavor, preserving the product’s quality throughout the supply chain.

Hygienic design is central to the Automated Pizza Production Line. Stainless steel construction, clean-in-place systems, and seamless machine interfaces reduce contamination risks while ensuring compliance with global food safety standards. These systems are also highly energy-efficient, utilizing advanced technologies to reduce water, electricity, and heat consumption.

Scalability and adaptability are key benefits of the Automated Pizza Production Line. Modular systems allow manufacturers to expand capacity or introduce new product varieties with minimal disruption. In a competitive, fast-moving market, this flexibility enables producers to stay ahead of shifting consumer trends while maintaining operational efficiency and profitability.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line YL-W-02 Commercial Water Purification Equipment

YL-W-02 Commercial Water Purification Equipment Jam Making Equipment

Jam Making Equipment Multifunctional Food Packaging Machine

Multifunctional Food Packaging Machine Pita Production Line

Pita Production Line Commercial Stufed Meatball Forming Machine

Commercial Stufed Meatball Forming Machine Potato Washing&Peeling Machine

Potato Washing&Peeling Machine Quail Egg Processing Line

Quail Egg Processing Line