How to Choose the Right Ramen Noodle Processing Line: A Complete B2B Buyer’s Guide

Introduction

The global instant and fresh ramen market has seen unprecedented growth in recent years, fueled by rising consumer demand for convenient, high-quality, and diverse noodle products. For food manufacturers, restaurant chains, or industrial processors, investing in a ramen noodle processing line is a strategic decision that can significantly impact production efficiency, product quality, and profitability.

However, purchasing a production line is not simply about buying machinery—it involves evaluating capacity, automation, product quality, food safety, cost efficiency, and after-sales support. Selecting the right manufacturer is equally crucial, as it can determine the long-term success of your investment. This article explores the key factors B2B buyers consider when acquiring ramen noodle processing equipment and strategies for manufacturers to stand out in a competitive market.

1. Production Capacity and Automation

One of the primary concerns for B2B buyers is whether the production line meets their required output and operational flexibility.

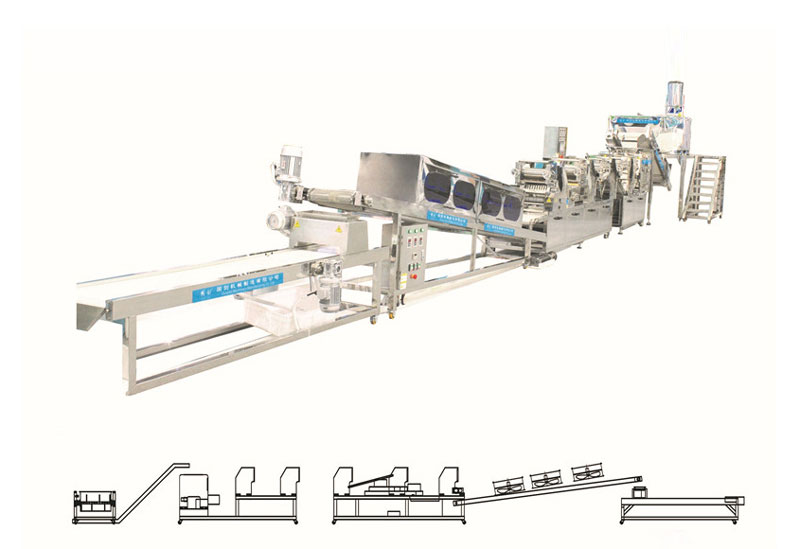

Continuous production capabilities: Buyers prefer lines that cover the entire process—from dough mixing, kneading, sheet rolling, cutting, steaming, drying or frying, to packaging—ensuring seamless operations without bottlenecks.

Specified output: Whether producing 100, 500, or 1,000 kilograms per hour, the production capacity must align with market demand and sales forecasts.

Flexibility for batch adjustments: Modern ramen lines should support multiple noodle types and adjustable production volumes, enabling manufacturers to respond quickly to seasonal or market changes.

A production line with optimal automation reduces human error, ensures consistent output, and lowers labor costs—critical factors for industrial-scale food processing.

2. Equipment Stability and Build Quality

Stability and durability are decisive for B2B buyers making high-value investments in production lines.

Reliable long-term operation: Industrial buyers are wary of frequent breakdowns and downtime, which can disrupt supply chains. A stable line ensures consistent production schedules.

High-quality components: Key parts such as motors, PLCs, sensors, and electrical components should be sourced from reputable international brands to ensure reliability and longevity.

Material durability: Stainless steel (304 or 316) for all surfaces in contact with food is essential to resist corrosion and maintain hygiene standards.

Investing in robust and precise equipment minimizes maintenance costs and extends the operational lifespan of the production line.

3. Product Quality and Consistency

For food processors, the final product quality is a non-negotiable criterion:

Uniformity: Noodle thickness, length, and texture must remain consistent across batches to satisfy consumers and ensure packaging efficiency.

Process control: Accurate management of temperature, pressure, steaming time, and drying conditions ensures proper texture and prevents over- or under-processing.

Versatility: Modern lines should handle fresh noodles, dried noodles, or fried varieties, allowing manufacturers to diversify product offerings.

High consistency reduces product rejection rates and strengthens brand credibility in competitive markets.

4. Cleanliness and Maintenance

Hygiene and ease of maintenance are critical considerations for buyers.

CIP (Cleaning-in-Place) systems: Lines equipped with CIP simplify cleaning processes and reduce downtime between production runs.

Ease of disassembly: Machines designed for quick dismantling facilitate routine maintenance and sanitation.

Standardized spare parts: Readily available replacement parts minimize operational interruptions and prevent prolonged downtime.

Efficient maintenance systems ensure long-term operational efficiency and compliance with food safety standards.

5. Food Safety and Compliance

B2B buyers prioritize equipment that meets strict international and local food safety standards:

Compliance with HACCP, ISO 22000, CE, FDA is often mandatory for commercial buyers, especially if products are intended for export.

Use of food-grade stainless steel and hygienic design prevents contamination.

Proper zoning and workflow in the production line help prevent cross-contamination between raw and cooked ingredients.

Regulatory compliance protects both consumers and the buyer’s investment in brand reputation.

6. Energy Efficiency and Cost Management

Operational costs, including energy consumption and labor, directly impact ROI.

Energy and steam optimization: Ramen noodle lines involve processes like steaming and drying, which are energy-intensive. Efficient equipment reduces electricity and steam costs.

Automation reduces labor costs: Automated feeding, cutting, and packaging minimize the need for manual intervention.

ROI visibility: Buyers prefer lines that demonstrate clear payback periods through increased efficiency, reduced labor costs, and consistent product quality.

Cost-effective, energy-efficient designs provide long-term financial benefits and sustainability advantages.

7. After-sales Service and Technical Support

A manufacturer’s support infrastructure can influence the purchasing decision as much as equipment quality.

Installation and training: Buyers expect comprehensive on-site installation and operational training to ensure smooth commissioning.

Technical support: Rapid response for troubleshooting, either remotely or through local service centers, reduces downtime risks.

Spare parts logistics: Prompt delivery of spare parts ensures continuous production without significant interruptions.

Reliable support builds trust with B2B buyers, especially for international clients with high-value equipment.

8. Customization and Scalability

Modern food processors require production lines that can adapt to market demands.

Expandable capacity: Lines should be designed with scalability in mind, allowing future upgrades without major reconstruction.

Specialty recipes: Manufacturers may require support for low-oil, gluten-free, or fortified noodle recipes.

Packaging flexibility: The line should accommodate multiple pack sizes and types, from retail pouches to bulk industrial packaging.

Customization and scalability help buyers maintain competitiveness in evolving markets.

9. How Manufacturers Can Stand Out

With numerous suppliers in the market, manufacturers must differentiate themselves to attract B2B clients:

End-to-end solutions: Offer complete services including recipe development, process optimization, workshop layout, and full installation support.

Highlight certifications: CE, ISO22000, FDA certifications provide assurance of quality and regulatory compliance.

Demonstrate ROI: Case studies with measurable improvements in capacity, efficiency, and labor savings build buyer confidence.

Technological edge: Smart control systems, automation, and remote monitoring increase operational reliability and reduce human error.

Robust after-sales network: Local service points and rapid spare parts availability enhance trust.

Brand differentiation: A professional online presence, SEO-optimized content, product videos, and trade show participation reinforce credibility.

Conclusion

Purchasing a ramen noodle processing line is a complex, high-value investment for B2B buyers. The most critical factors include production capacity, stability, product quality, food safety, cost efficiency, and after-sales support.

Manufacturers who provide comprehensive solutions, reliable certifications, clear ROI metrics, technological advantages, and responsive service can effectively differentiate themselves in a competitive market.

By understanding buyer priorities and demonstrating value through technology, quality, and support, both buyers and manufacturers can achieve mutually beneficial outcomes in the rapidly growing ramen noodle industry.

Must-Read Blogs For Chain Restaurants Owner

The Double-Door Steaming Cabinet With A Viewing Window

The Double-Door Steaming Cabinet With A Viewing Window Sausage Stuffer Machine

Sausage Stuffer Machine Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

Chicken Plucker Machine

Ready to Get Started?