Poultry Processing Line - Chinese Manufacturer, Factory, Supplier

The modern Poultry Processing Line is a cornerstone of efficiency, hygiene, and scalability within the global food industry. It transforms the complexities of poultry slaughtering, evisceration, chilling, and portioning into a seamless, automated sequence that ensures both food safety and product consistency. As global demand for high-quality poultry products increases, the importance of investing in state-of-the-art Poultry Processing Line solutions has never been more pronounced.

A typical Poultry Processing Line integrates a series of specialized modules, each meticulously engineered to handle specific stages of the process. From live bird handling and stunning to defeathering, evisceration, chilling, grading, and packaging, every step is designed with precision to maintain the highest standards of hygiene and operational efficiency. Advanced lines incorporate computer vision systems, automated weighing, and intelligent cutting equipment to maximize yield and minimize waste — critical factors in today’s competitive market.

One of the defining advantages of a modern Poultry Processing Line is its capacity for continuous, high-speed operation without compromising on quality. These lines are capable of processing thousands of birds per hour, offering scalable solutions for both small-scale plants and industrial mega-factories. Modular design allows processors to expand or upgrade specific sections as needed, aligning investment with production goals.

Hygiene remains a paramount consideration throughout the Poultry Processing Line. Stainless steel construction, easy-to-clean surfaces, and CIP (Clean-in-Place) systems are standard features. These design elements not only enhance sanitation but also extend equipment longevity and reduce downtime due to maintenance. Furthermore, compliance with international food safety standards ensures that end products meet the expectations of discerning global markets.

Energy efficiency and sustainability are also driving innovation in Poultry Processing Line technology. Modern lines leverage energy-saving motors, water recycling systems, and waste recovery solutions to reduce environmental impact and operating costs. This eco-conscious approach aligns with broader industry trends towards greener, more responsible production practices.

In today’s fast-evolving market landscape, automation is no longer optional — it is a necessity. The Poultry Processing Line stands at the forefront of this transformation, offering processors the tools they need to enhance throughput, guarantee food safety, and improve profitability. As consumer expectations evolve and regulatory scrutiny intensifies, investing in advanced poultry processing solutions remains a strategic imperative for future-ready food businesses.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Donut Making Machine

Donut Making Machine Commercial Pasta Sheeter

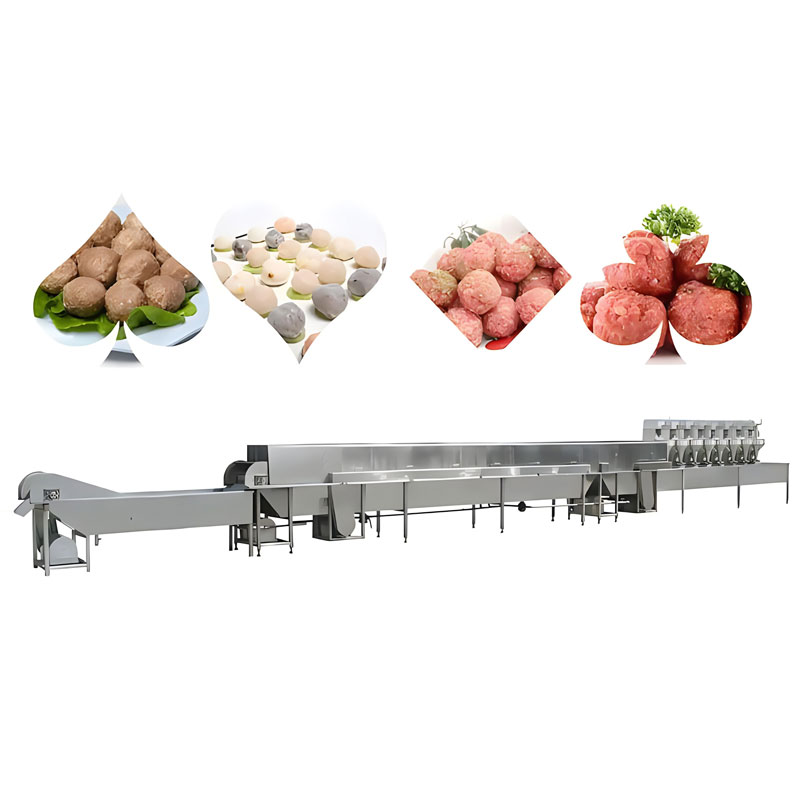

Commercial Pasta Sheeter Meatball Production Line

Meatball Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line The Double-Door Steaming Cabinet With A Viewing Window

The Double-Door Steaming Cabinet With A Viewing Window Chicken Nugget Processing Line

Chicken Nugget Processing Line Fried Food Deoiling Machine

Fried Food Deoiling Machine