Key Processes and Core Equipment of Chili Sauce Production Line

With the continuous expansion of the global condiment market, chili sauce has become one of the most sought-after products due to its distinctive spicy flavor and wide range of culinary applications. From China's Sichuan-style chopped chili to Hunan fermented chili paste, Korean gochujang, and Mexican chili purée, consumer demand for chili-based condiments remains strong worldwide. For food processing enterprises, establishing a standardized, large-scale, and food-safe chili sauce production line is essential for enhancing market competitiveness and profitability.

This comprehensive article dissects the entire industrial chili sauce production process, from raw material handling to end-product packaging. Focusing on the practical needs of B2B food equipment procurement professionals, it offers in-depth analysis of key production stages, core equipment functions, selection criteria, and operational essentials—empowering businesses to plan production lines scientifically, improve efficiency, and safeguard product consistency while minimizing procurement risks.

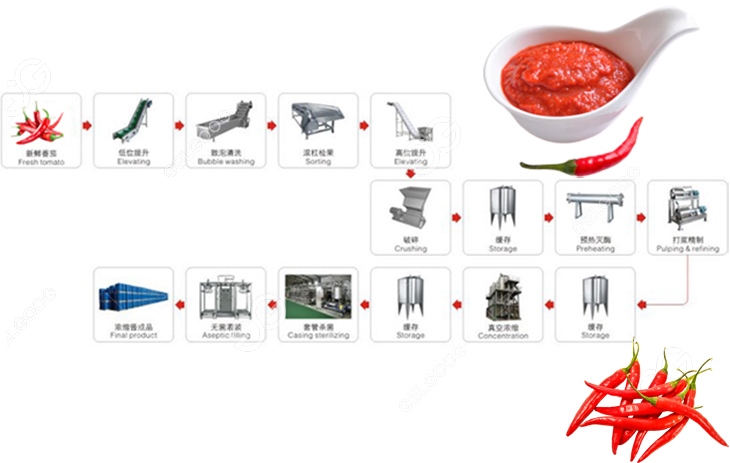

Standardized Chili Sauce Production Process Overview

A complete industrial chili sauce production line typically includes the following stages:

Raw Material Preprocessing → Coarse Crushing & Grinding → Ingredient Mixing → Cooking & Sterilization → Filling & Sealing → Packaging & Palletizing

Each stage is interconnected yet operates as an independent module. The rationality and technological advancement of each directly determine production efficiency, product texture, flavor consistency, and shelf life.

Raw Material Preprocessing — The First Step to Food Safety

As agricultural products, fresh chilies inevitably carry soil, pesticide residues, foreign matter, and microbes during harvesting, transport, and storage. A rigorous raw material preprocessing procedure is the foundation for safe, hygienic production and stable end-product quality.

Key Equipment Overview

1️⃣ Washing Equipment

Bubble Washing Machines / Spray Washing Machines / Brush Washing Machines

Combined multi-stage cleaning for thorough decontamination.

Bubble agitation: Gently removes floating dirt and soil.

High-pressure spraying: Further rinses surface residues.

Brush rollers: Clean surface grooves and stubborn impurities.

Selection Criteria: Water recycling system design, adjustable spray pressure, cleaning efficiency, easy drainage.

2️⃣ Destemming & Deseeding Equipment

Rotary Destemming Machines / Airflow Deseeding Machines

Effectively remove stems to reduce impurities in the final product.

Airflow separates lightweight chili seeds, enhancing paste purity and authentic flavor.

Selection Criteria: Durability, separation precision, low material loss, compatibility with various chili types.

3️⃣ Chopping Equipment

Variable-Speed Choppers / Disc Cutters

Provides uniform particle size for stable subsequent colloid milling.

Adjustable granularity meets different sauce textures (chunky or smooth).

Selection Criteria: Stainless steel blades (304), adjustable speed, wear resistance, easy maintenance.

Grinding & Pulping — Defining the Fineness of Chili Sauce

One of the key selling points of chili sauce lies in its smooth, homogeneous texture. Whether it clings well to surfaces, whether it separates during storage, and whether its particles are too coarse directly influence consumer satisfaction and brand reputation.

Key Equipment Overview

1️⃣ Colloid Mill

High-speed shearing and centrifugal force refine chili fragments into a uniform slurry.

Continuous process, high efficiency, suitable for viscous, fibrous materials.

Production Scale: Essential for medium to large-scale operations.

Advantages: Adjustable fineness, stable performance, low maintenance.

2️⃣ Homogenizer

High-pressure impact homogenizes particle size distribution, improving mouthfeel and product stability.

Prevents separation, syneresis, and color inconsistencies.

Ideal For: High-end or export-oriented products demanding superior smoothness and shelf life.

3️⃣ Stone Mill (Traditional Craft)

Mimics manual slow-grinding, preserving authentic flavors.

Limited capacity, suitable for specialty small batches or premium product lines.

Ingredient Mixing — Ensuring Flavor Consistency and Stability

Chili sauce recipes typically include salt, sugar, oil, spices, preservatives, etc. Accurate dosing and uniform blending are crucial for consistent flavor profiles and food safety compliance.

Key Equipment Overview

1️⃣ Automatic Dosing Systems

Electronic weighing + PLC precision control.

Multiple ingredient ports, automatic traceability for batch management and food safety compliance.

Advantages: Reduces human error, ensures formula consistency, enhances management efficiency.

2️⃣ Vacuum Mixing Tank / Regular Mixing Tank

Vacuum Mixing: Prevents oxidation, locks color and aroma, extends shelf life.

Variable-speed agitators: Suitable for various viscosities, ensuring homogeneous mixing without dead zones.

Jacketed Structure: Supports heating/cooling, aids emulsification/mixing.

Selection Criteria: Mixing type (anchor, paddle), frequency converter, adaptability to material properties, hygienic design.

Cooking & Sterilization — Enhancing Flavor and Shelf Stability

Cooking not only enhances the flavor profile by releasing chili aromas but also ensures microbiological safety through effective sterilization, securing the product’s shelf life.

Key Equipment Overview

1️⃣ Jacketed Kettle (Cooking Pot)

Steam / electric heating with temperature and time control.

Manual / automatic discharge systems suitable for different production scales.

Production Capacity: Ideal for small to medium workshops / semi-automated lines.

2️⃣ Continuous Cooking Systems

Fully automated temperature and time control for process stability.

Continuous feeding and discharging improve efficiency and consistency.

Production Capacity: Suitable for medium to large food factories with continuous production.

3️⃣ Sterilization Equipment

Pasteurization Machines: Gentle sterilization preserves color and flavor.

HTST Instant Sterilization Machines: High-temperature short-time sterilization for extended shelf life, widely used for export products.

Selection Criteria: Align with desired shelf life, microbial standards, and market distribution channels (ambient or refrigerated).

Filling & Packaging — Standardizing Presentation, Boosting Efficiency

Standardized filling and packaging not only improve production efficiency but also ensure consistency, strengthen shelf appeal, and enhance market competitiveness.

Key Equipment Overview

1️⃣ Filling Machines

Piston Filling Machines: For viscous chili sauces, precise dosing, drip-free.

Vacuum Filling Machines: For vacuum-fresh sealing (glass bottles).

Core Features: Servo control, anti-stringing, anti-drip design.

2️⃣ Capping / Sealing Machines

Automated positioning and capping, ensuring tight seals to prevent leakage and oxidation.

3️⃣ Labeling Equipment

Automated positioning, precise labeling for round, square, or irregular containers.

4️⃣ Cartoning / Palletizing Equipment

Automated case packing and palletizing, enhancing logistics efficiency and reducing labor costs.

Smart Auxiliary Systems — Ensuring Smooth, Stable Operation

Modern chili sauce production lines require essential auxiliary systems:

Conveying systems (spiral, belt) for efficient material transfer.

Automatic CIP cleaning systems for hygiene and labor reduction.

Vacuum systems for mixing and filling support.

PLC + Touchscreen + SCADA for centralized management, data traceability, and remote monitoring.

Recommended Production Line Configurations by Scale

| Scale | Daily Output (Tons) | Recommended Configuration | Investment Estimate (RMB) |

|---|---|---|---|

| Small Workshop | 1-3 | Semi-automatic machines + manual support | 500K-800K |

| SME | 5-15 | Continuous processing + automated dosing + filling & packaging line | 1.5M-3M |

| Industrial Plant | 20+ | Fully automated continuous line + smart systems | 5M+ |

Procurement Recommendations for Equipment

1️⃣ Define product positioning (smooth, chunky, traditional flavor, export-focused, etc.).

2️⃣ Plan production capacity rationally with scalability in mind.

3️⃣ Choose established brands; prioritize core components (controls, seals, bearings).

4️⃣ Evaluate supplier’s track record, delivery capacity, and after-sales service.

5️⃣ Conduct live testing to verify performance and data reliability.

Industry Trends and Future Equipment Directions

Consumer upgrades drive product diversification; differentiated flavors open new growth opportunities.

Automation and digitalization help food enterprises reduce costs and enhance efficiency.

Green and environmentally friendly equipment (energy-saving, emission control) becomes the industry standard.

Smart traceability systems (barcodes, QR codes) ensure food safety supply chain integration.

Conclusion

Although chili sauce belongs to the traditional condiment category, modern food industry standards impose higher requirements for its quality and safety. Building a systematic, standardized, and automated production line is fundamental for maintaining a company’s competitiveness and profit margins. Every production stage’s equipment selection must align with actual business needs, following a scientific, pragmatic, and future-oriented procurement philosophy.

Sound investment choices ensure food safety, reduce operating costs, and enhance brand image—an indispensable strategy for every food enterprise.

For customized factory layouts, equipment quotations, or production line planning, consult experienced professional equipment manufacturers for one-stop solutions.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?