Top 10 Commercial Food Processing Project Solution Providers in China

China’s Global Position in the Food Processing Industry

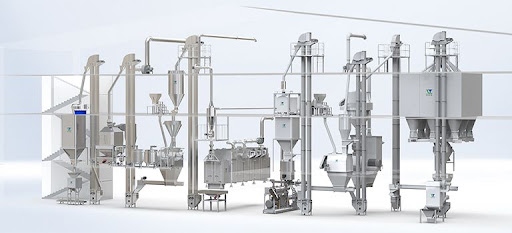

China has become a dominant player in the global food processing equipment and solutions market, not only due to its vast consumer base but because of its comprehensive industrial ecosystem and robust supply chain infrastructure. Over the past two decades, Chinese manufacturers have transformed from simple equipment suppliers into turnkey solution providers, earning trust from multinational brands worldwide.

According to the China National Food Industry Association, the output value of China's food equipment sector exceeded 1.2 trillion RMB in 2024, with exports maintaining annual growth of over 12%. These solutions cover everything from beverages, dairy, pre-cooked meals, seafood, snacks, and condiments with increasingly sophisticated capabilities.

Competitive Advantages of Chinese Food Processing Solution Providers

🔹 1. Complete Industrial Chain, Global Integration

Chinese companies deliver not only individual machines but end-to-end solutions covering:

Raw material pre-processing

Core processing

Filling, sterilization, packaging

Logistics and warehousing

China excels in areas such as:

Dairy (UHT, pasteurization, aseptic filling)

Fruit & vegetable processing (concentrates, canned, frozen)

Beverages (carbonated drinks, bottled water, functional beverages)

Meat products & ready meals (cooking, frying, freezing, packaging)

🔹 2. Comprehensive Turnkey Project Expertise

Unlike Western suppliers, Chinese companies excel in EPC (Engineering, Procurement, Construction) turnkey delivery, offering:

Process design

Factory layout

Equipment manufacturing

Installation, commissioning, and staff training

All within a one-stop service framework, reducing project timelines and investment risks.

🔹 3. Leadership in Automation & Digitalization

With the push of “Industry 4.0” and “Made in China 2025”, top manufacturers offer:

Intelligent line control (PLC, touch screen centralized management)

IoT (Internet of Things) integration

ERP + MES smart factory systems

Full lifecycle traceability and visual management

These technologies ensure transparency, efficiency, and traceability throughout production.

🔹 4. Responsive After-Sales & Export Expertise

Leading providers maintain global service networks, ensuring swift access to:

Maintenance

Spare parts

Technical upgrades

Their certifications (CE, FDA, ISO, etc.) and decades of export experience make them reliable partners for Europe, Southeast Asia, the Middle East, and beyond.

Top 10 Food Processing Project Solution Providers in China (In-Depth Analysis)

These companies represent the elite tier of China's industry, renowned for their international project delivery capabilities, servicing Fortune 500 brands and regional market leaders.

| Rank | Company | Core Strength | Key Project Areas | Global Presence |

|---|---|---|---|---|

| 1 | Shanghai Jimei Food Machinery Co., Ltd. | 40 years’ experience, full-sector | Beverage, dairy, fruits, condiments | Belt & Road focus |

| 2 | Zhucheng Tianshun Machinery Co., Ltd. | Sterilization expertise, automation | Meat, canned, ready meals | Asia, Middle East |

| 3 | Shanghai Chase Industrial Co., Ltd. | Strong engineering, project management | Fruit processing, concentrates, cold chain | Europe, Americas |

| 4 | Jiangsu Jinrong Machinery Co., Ltd. | Renowned in beverage industry | Beverage, dairy, condiments | North America, Africa |

| 5 | Shanghai Triowin Intelligent Machinery | Smart factories, MES integration | Intelligent beverages, fruit factories | Asia, Americas |

| 6 | Guangzhou XTIME Packaging Equipment | Integrated packaging systems | Pouches, bottles, cans | Southeast Asia, Africa |

| 7 | Beijing Yuanfang Technology Co., Ltd. | Smart factory solutions | Automation control, digital factory | China, ASEAN |

| 8 | Hangzhou Huihe Machine Factory | Small-mid enterprise solutions | Beverages, fruits, condiments | Southeast Asia, Europe |

| 9 | Dalian Reyes Import & Export Co., Ltd. | Seafood expertise, export strength | Canned, frozen seafood, pet food | Japan, Americas |

| 10 | Zhucheng Zhongrui Machinery Co., Ltd. | Continuous sterilization leadership | Ready meals, high-temp foods | Asia, Middle East |

How to Choose the Right Partner? A Comprehensive Decision-Making Guide

📌 Key Evaluation Criteria

| Factor | Key Questions |

|---|---|

| Project Experience | Does the company have proven cases in your sector? |

| Delivery Capacity | Can they handle EPC end-to-end efficiently? |

| Technical Strength | Do they excel in automation, digitalization, green manufacturing? |

| Compliance | Are they certified for CE, FDA, ISO standards? |

| After-Sales Support | Do they maintain overseas service hubs with rapid response? |

| Cost Efficiency | Can they offer flexible solutions within budget and timeline? |

📌 Matching Your Business Growth Stage

Start-ups: Prioritize ROI and scalability; consider Hangzhou Huihe or Guangzhou XTIME.

Growth Stage: Focus on stable capacity and standardization; Shanghai Jimei or Jiangsu Jinrong fit well.

Expansion Stage: Emphasize smart manufacturing and sustainability; Shanghai Triowin or Beijing Yuanfang are optimal.

Challenges & Opportunities in China’s Food Processing Project Sector

Current Challenges

Stringent international food safety regulations

Rising labor costs fueling automation demand

Environmental pressures on traditional energy-intensive equipment

Future Opportunities

1. Southeast Asia, Middle East, Africa – Emerging Blue Oceans

These regions seek turnkey food plants amid rapid industrialization.

2. Pre-cooked Meals & Snack Foods – Booming Segments

Driving demand for sterilization, ready meals, freezing, and packaging solutions.

3. Dual Focus on Green & Smart Factories

China’s double-carbon policy accelerates demand for energy-efficient, intelligent production lines.

Future Trends Shaping the Industry

| Trend | Technology Path | Expected Benefits |

|---|---|---|

| Smart Factories | MES + ERP + IoT + AI | Visibility, intelligent management, efficiency |

| Flexible Production | Quick-switch technology, modular lines | Multi-variety adaptability |

| Green Manufacturing | Energy recovery, water recycling | Cost reduction, compliance |

| Safety & Traceability | Big Data + Blockchain Systems | Food safety, brand trust |

| Intelligent Maintenance | AR remote services, digital twin | Reduced downtime, higher efficiency |

Expanded FAQs: About China’s Food Processing Project Providers

1️⃣ Can Chinese providers meet US/EU standards for turnkey projects?

Absolutely. Most leading firms hold CE, FDA, ISO22000 certifications and serve global brands like Coca-Cola, Nestlé, Pepsi.

2️⃣ Do they offer green factory and sustainability solutions?

Yes. Providers integrate energy-saving, water recycling, and carbon management systems aligned with ESG goals.

3️⃣ Is after-sales service robust internationally?

Yes. Top firms maintain subsidiaries or partners in Southeast Asia, Middle East, Europe, Americas, with on-site engineers.

4️⃣ How reliable are delivery timelines?

With integrated supply chains and flexible manufacturing, delivery is typically 30-50% faster than Western counterparts.

5️⃣ Can they handle fully customized solutions?

Yes, particularly in condiments, snacks, beverages, dairy—tailored to specific production processes.

6️⃣ Do they support digital factory development?

Yes. Solutions include ERP, MES, SCADA, WMS smart management systems.

Conclusion: Why More Global Enterprises Choose China for Food Processing Solutions

✔ Proven project experience

✔ Advanced technical capabilities

✔ Stable, resilient supply chains

✔ Cost-effective flexibility

✔ Comprehensive global service networks

China’s top food processing solution providers continue to redefine industry benchmarks through their industrial depth and future-forward innovation, positioning themselves as strategic partners for businesses worldwide.

Must-Read Blogs For Chain Restaurants Owner

Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line

Ready to Get Started?