Frozen Pizza Production Line - Chinese Manufacturer, Factory, Supplier

The Frozen Pizza Production Line represents a sophisticated integration of automation, precision engineering, and food technology. It is designed to streamline the complex process of manufacturing high-quality frozen pizzas at scale, ensuring consistency in flavor, texture, and appearance across every batch. From dough preparation to final packaging, each stage is meticulously calibrated to maintain strict hygiene standards and operational efficiency.

A typical Frozen Pizza Production Line begins with dough mixing and proofing, followed by automated sheeting and shaping to achieve the desired base thickness and diameter. Advanced systems ensure uniformity and control, which is crucial for maintaining product integrity during baking and freezing. Sauce application, cheese distribution, and toppings placement are handled through precision dosing equipment, minimizing waste while maximizing visual appeal.

High-performance ovens form the heart of the Frozen Pizza Production Line, delivering consistent baking results through precise temperature control and conveyor speed adjustments. Rapid freezing systems then lock in freshness and preserve the pizza’s sensory qualities, from its crisp crust to its rich toppings. Finally, automated packing machines wrap, label, and palletize the finished products, ready for distribution to retail and foodservice markets.

Energy efficiency, ease of cleaning, and modular flexibility are core features of modern Frozen Pizza Production Line solutions. These lines are engineered for scalability, allowing producers to adapt to changing market demands or introduce new product variations with minimal disruption.

For manufacturers seeking to meet growing consumer demand for convenient, high-quality frozen foods, investing in a Frozen Pizza Production Line offers a pathway to increased productivity, reduced operational costs, and enhanced product consistency. It is a strategic asset for businesses looking to strengthen their competitive edge in the dynamic frozen food sector.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Cake Production Line

Cake Production Line Biscuit Making Machine

Biscuit Making Machine Screw Potato Peeling Washing Machine

Screw Potato Peeling Washing Machine SD Square Ice Series Upright Ice Makers

SD Square Ice Series Upright Ice Makers Dough Kneader Machine

Dough Kneader Machine Crisp Production Line

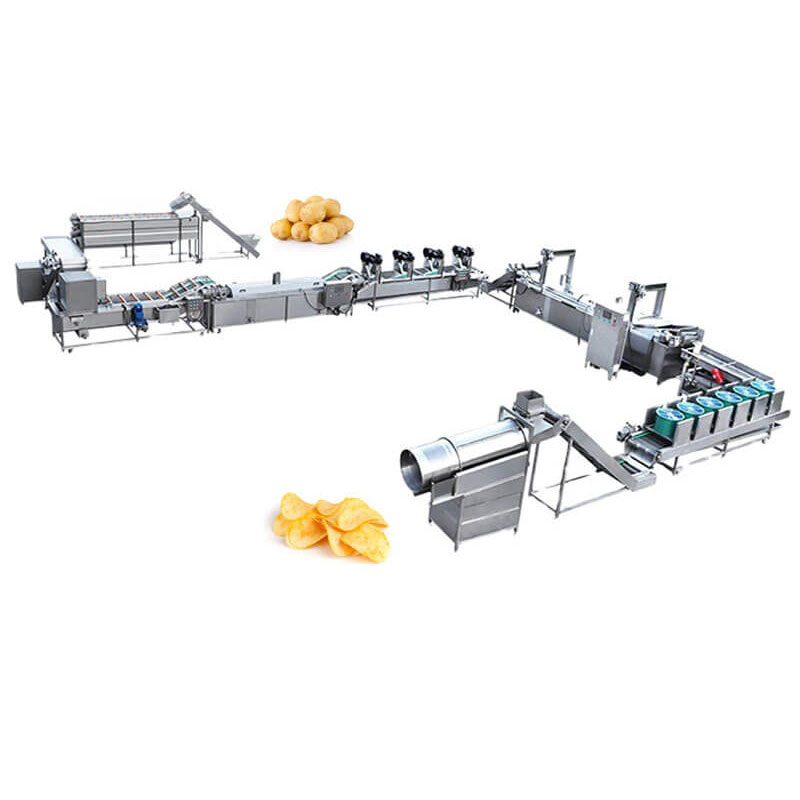

Crisp Production Line Semi-automatic Potato Crisps Production Line

Semi-automatic Potato Crisps Production Line