Key Considerations Before Investing in an Automated Bakery Production Line

In today’s baking industry, automation is no longer optional—it’s essential. As demand grows, labor becomes scarcer, and quality expectations rise, more bakeries are investing in automated production lines to scale efficiently, reduce waste, and improve consistency.

However, purchasing automated baking equipment is a major capital decision. The right line can boost your business for a decade. The wrong one can stall your production, strain your budget, and limit product flexibility.

This guide walks you through six core considerations that every bakery decision-maker should evaluate before signing a purchase order—so you choose a solution that’s cost-effective, scalable, and built for your product mix.

1️⃣ Your Bakery’s Size & Output: Match Automation Level to Your Volume

Not all bakeries need full-line automation. Choosing the right degree of automation depends on your current output and future growth expectations.

| Bakery Type | Recommended Automation | Why It Works |

|---|---|---|

| Small Artisanal Bakery (≤500kg/day) | Partial automation (e.g. mixers, proofers) | Keeps the handmade feel while improving efficiency |

| Medium Bakery (500–3000kg/day) | Modular or semi-automatic line | Balances speed with product variety |

| Large Central Factory (≥3000kg/day) | Full automation | Continuous, high-volume production for wholesale/retail contracts |

Ask yourself:

Are you maxing out your current team’s capacity?

Do your peak seasons cause delays or quality drops?

Is your main business B2C retail or B2B wholesale?

2️⃣ Product Variety: Can the Line Handle Your Doughs, Shapes, and Fillings?

Modern bakeries rarely make one type of product. You may produce sourdough loaves in the morning, filled buns in the afternoon, and sweet pastries overnight.

Your line needs to handle:

Different dough types: High-hydration, enriched, gluten-free

Shapes & sizes: Baguettes, rolls, braided loaves, buns

Filled products: Chocolate, cheese, fruit, cream

✅ What to check:

Are changeovers fast and tool-free?

Can the forming section adapt to varied weights and shapes?

Are filling nozzles precise and clog-resistant?

Is the line designed for mixed-SKU production in one shift?

Ask your equipment supplier for video demos or live trials of your actual products on their system.

3️⃣ Floor Space & Layout: Automation Needs Room to Flow

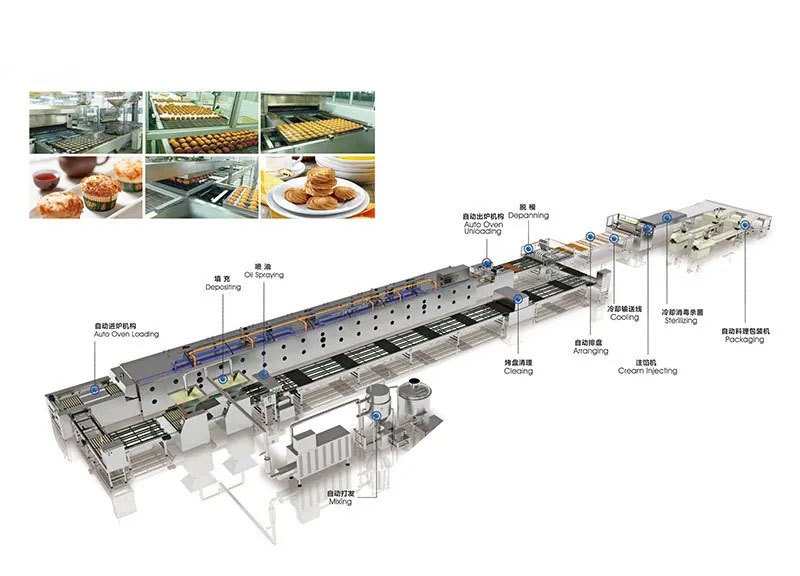

A full bakery production line includes mixers, dividers, proofers, shapers, ovens, cooling tunnels, and packaging. A compact operation may need just 80–150 m². Large systems could require over 500 m².

Key layout concerns:

Can the equipment fit seamlessly into your current space?

Are you planning for efficient material flow (dough in → packaged goods out)?

Will the setup allow for future modules (e.g., automated packing)?

Are ventilation, electrical, and drainage systems properly positioned?

Pro tip: Many suppliers offer custom layout planning—ask for a 2D/3D CAD plan based on your facility.

4️⃣ Budget & Financing: Think Beyond Purchase Price—Think Total ROI

It’s easy to focus on upfront costs—but smart buyers look at total return over 5–10 years.

Sample ROI Calculation:

ROI = (Monthly savings × 12 × Expected lifespan) ÷ Total equipment cost

Example:

Labor & waste savings per month = $4,000

Expected usage = 7 years

Equipment cost = $150,000

ROI = ($4,000 × 12 × 7) ÷ $150,000 = 2.24 → 224% return over 7 years

Also ask about:

Financing plans or lease-to-own options

Tax depreciation schedules and government equipment subsidies

Whether the machine can help you secure bigger contracts

5️⃣ Scalability: Will the Line Grow with Your Business?

You’re not just buying equipment for today—you’re investing in your bakery’s next chapter. Choose a line that can scale as your demand increases.

Key scalability features:

Modular design—add cooling tunnels, packagers, slicers later

Open architecture for software upgrades and MES integration

Pre-installed I/O ports and sensors for IoT expansion

Compatibility with industry certifications (BRC, FSMA, HACCP) for future compliance

Avoid closed systems that require full replacement to expand.

6️⃣ After-Sales Support: You’re Buying a Long-Term Partnership

Even the best machines need maintenance. A trusted supplier should offer end-to-end support, not just shipping and installation.

Must-ask questions:

What’s the response time for technical issues?

Do they offer on-site support or remote assistance?

Are critical spare parts stocked locally?

Is operator training included?

Can software be updated remotely or upgraded later?

Tip: Review real testimonials or case studies before committing.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?