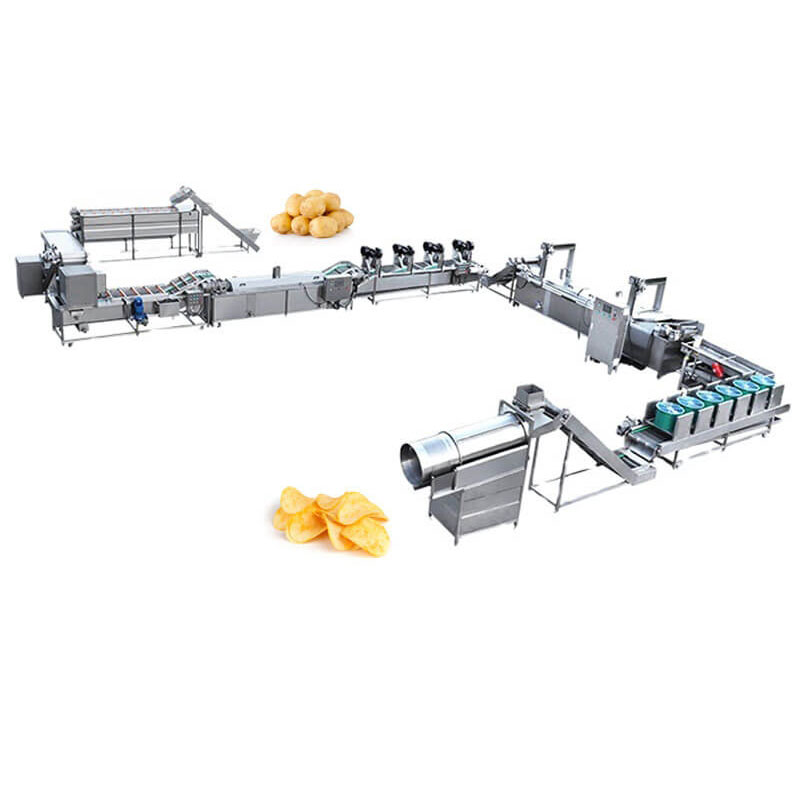

🔧 Product Overview

Our Automatic Potato Chips Production Line is an industrial-grade solution designed for high-efficiency, large-scale potato chips manufacturing. From potato washing to final packaging, every step is fully automated—ensuring consistent quality, minimized labor cost, and streamlined production. This line is ideal for food processing factories looking to expand capacity, standardize product quality, and meet increasing market demand.

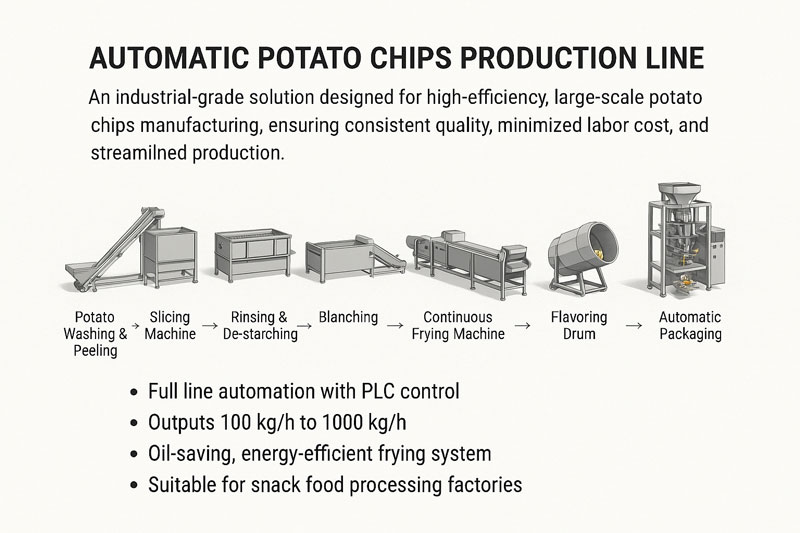

✅ Core Processing Flow

Potato Washing & Peeling

Efficient drum-type cleaning and peeling machine removes mud and skins.

Slicing Machine

Adjustable cutting thickness with uniform precision. Wavy or flat chips optional.

Rinsing & De-starching

Cold water rinsing removes surface starch, improves texture and frying quality.

Blanching

Thermal treatment stabilizes color and flavor while extending shelf life.

De-watering

High-speed centrifuge reduces water content before frying, reducing oil consumption.

Continuous Frying Machine

Automatic temperature control and oil filtration system for energy-efficient, uniform frying.

De-oiling & Cooling

Removes excess oil and cools chips for crispiness.

Flavoring Drum

Rotating drum ensures even flavor distribution with adjustable spray systems.

Automatic Packaging

Multi-head weighing and sealing machines tailored to various bag types and volumes.

⚙️ Technical Specifications (Customizable)

| Parameter | Value |

|---|---|

| Capacity Options | 100 kg/h – 1000 kg/h |

| Power Supply | 380V / 50Hz (Customizable) |

| Material | SUS304 Stainless Steel |

| Automation | PLC Control + Touchscreen HMI |

| Heating Options | Electric / Gas / Diesel |

| Packaging Types | Pillow bag, gusseted bag, canister, etc. |

🏭 Application Scenarios

Snack food processing factories

Industrial potato processing plants

Contract manufacturing operations

Frozen/prepared foods producers

💡 Key Advantages

Full Line Automation – Reduces labor and error, supports 24/7 continuous production

Stable Product Quality – Consistent slice thickness, fry time, and flavor coverage

Oil-Saving Frying System – Built-in filtration prolongs oil life, reduces cost

Customizable Layout – Adaptable to customer space and product format

Food-Grade Build – Complies with CE, ISO, and HACCP standards

📊 ROI & Profitability

Payback period: Typically within 12–18 months based on medium-scale production

Labor cost reduction: Up to 60% compared with semi-automatic lines

Yield rate: >95% output efficiency from raw potatoes

Oil savings: Up to 30% through optimized frying and filtration

🌍 Global Support & Custom Engineering

We offer end-to-end support from layout design, installation & commissioning, to after-sales service and spare parts supply. Our engineers can customize the line for local voltage, raw material size, chip types (plain, ridged, sticks), and packaging formats to suit your market.

📦 What’s Included in the Line

Washing & Peeling Machine

Slicing Machine

Blanching Machine

De-watering Unit

Continuous Fryer

De-oiling Conveyor

Flavoring System

Cooling Conveyor

Automatic Packing Machine

Optional add-ons: Metal detector, nitrogen flushing, oil tank with filtration system, CIP cleaning system.

Must-read blogs for bosses