Product Overview

The Fruit and Vegetable Canned Production Line is a fully customizable processing solution designed for food factories that produce canned peaches, pineapples, tomatoes, mixed vegetables, sweet corn, tropical fruits, and other shelf-stable products.

This production line supports flexible automation levels, ranging from semi-automatic modules to fully automated turnkey systems, making it suitable for large-scale manufacturers, newly built factories, and traditional plants upgrading from manual operations.

The line covers the complete canning process, including washing, sorting, cutting, blanching, filling, vacuum sealing, sterilization, cooling, labeling, and final packing. All equipment is made from food-grade stainless steel (304/316), compliant with HACCP, ISO, GMP, and global food safety standards.

With a capacity range from 500 kg/h to 5000 kg/h, this production line provides consistent quality, higher efficiency, lower labor costs, and stable product safety performance.

Key Features & Technical Advantages

1. Flexible Automation Design

You can choose semi-automatic or fully automated modules based on budget, plant layout, and output needs.

Available options include:

Automatic sorting and grading

Automatic filling and vacuum sealing

Continuous sterilization

Automated packaging line

MES/SCADA data monitoring

This flexibility ensures you get the optimal cost-performance ratio.

2. High-Efficiency Washing & Pre-processing

Professional equipment ensures raw materials are clean and safe:

Bubble washing machine removes dirt and impurities

Spray washing system with adjustable pressure

Roller or conveyor sorting system

Optical color sorter for premium-grade factories

This improves hygiene and reduces manual errors.

3. Precision Cutting & Preparing System

Designed for different materials:

Dicing, slicing, segment cutting, shredding

Adjustable thickness and size

Smooth cutting surface to reduce oxidation

Suitable for mango, peach, pineapple, tomato, carrot, bean, corn kernels, etc.

4. Advanced Blanching & Enzyme Inactivation

Blanching ensures stable color, texture, and flavor:

Temperature control from 85–100°C

Steam or hot-water blanching

Energy-saving heat recovery system

Automatic lifting and continuous feeding

This reduces nutrient loss and improves product shelf life.

5. High-Accuracy Filling System

Depending on product type (pieces, liquid, paste, brine), options include:

Volumetric filling

Servo piston filling

Weighing filling

Multi-head automated filling

Accuracy can reach ±1%, reducing waste and improving consistency.

6. Vacuum Sealing & Capping

Ensures can integrity and product freshness:

Tin can seaming

Glass jar capping

PP bottle capping

Vacuum or nitrogen flushing

Stable sealing reduces leakage and swelling issues.

7. Continuous Sterilization & Cooling

Sterilization methods include:

Retort sterilizer (batch)

Continuous spray sterilization

Rotary sterilizer

UHT+aseptic filling (for puree)

Temperature range: 121–135°C

Cooling system prevents overcooking and maintains product color.

8. Food Safety & Hygienic Design

All parts in contact with food use SUS304/316

Smooth welding, easy to clean

CIP automatic cleaning system available

Designed according to HACCP & GMP plant audit requirements

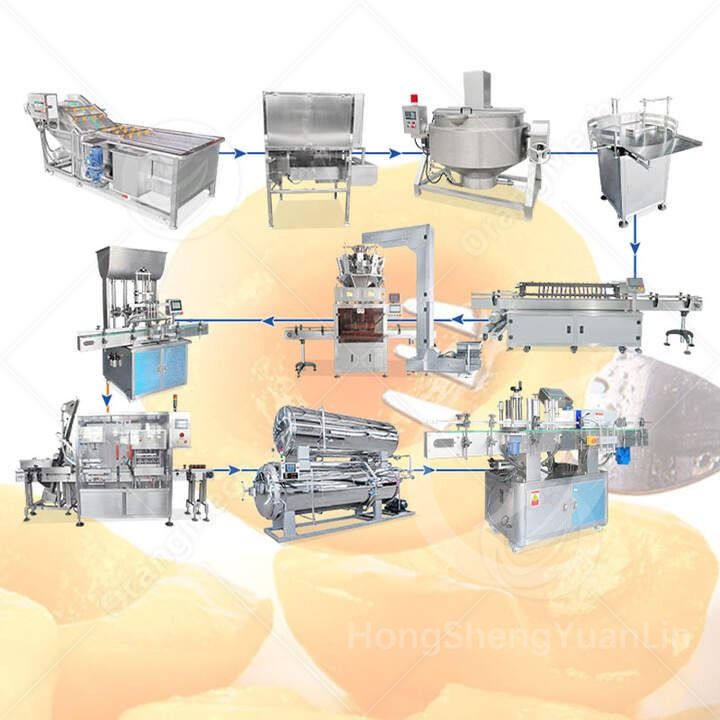

Complete Process Flow

A standardized industrial canning line usually includes:

Raw Material Receiving → Washing → Sorting & Grading → Cutting/Peeling → Blanching → Cooling → Filling → Vacuum Sealing → Sterilization → Cooling → Drying → Labeling → Packing → Warehouse

This clear and efficient workflow ensures stable production and predictable product quality.

Technical Specifications

| Item | Specification |

|---|---|

| Capacity | 500–5000 kg/h (customizable) |

| Applicable Products | Fruits, vegetables, tropical fruits, tomato products, corn, beans |

| Applicable Containers | Tin can, glass jar, bottle, retort pouch |

| Filling Accuracy | ±1% |

| Sterilization Temperature | 121–135°C |

| Power Supply | 220/380V, 50/60Hz |

| Material | SUS304/316 stainless steel |

| Automation Level | Semi-auto / fully automatic (customizable) |

| Control System | PLC + touch screen |

Applications

This production line is suitable for processing:

Canned peach, pear, pineapple

Mango, papaya, tropical fruits

Tomato paste, diced tomato, crushed tomato

Mixed vegetables

Sweet corn / whole kernel corn

Carrot, potato, bamboo shoots, beans

Fruit cocktail production lines

Customization Options

We offer full customization for:

Plant layout & factory design

Production capacity

Container type (can/jar/pouch)

Levels of automation (manual to fully automatic)

Labeling & packing solutions

Energy type (steam, electricity, gas)

CIP cleaning and data monitoring system

Our engineering team provides 2D/3D layout drawings and turnkey solution support.

Why Choose Us

20+ years manufacturing experience in food processing equipment

Complete turnkey factory solutions

Exported to more than 40 countries

Strong R&D and engineering team

HACCP, ISO, CE certified equipment

On-site installation, commissioning and staff training

Lifetime technical support and spare parts supply

We help new factories start smoothly and assist traditional factories in upgrading to automation.

FAQ

1. What capacity range does your production line support?

We provide 500–5000 kg/h standard models, and we can customize according to your plant size and market needs.

2. Can this line process both fruits and vegetables?

Yes. Different cutting, blanching, and filling modules can be configured for multi-material processing.

3. What type of container can be used?

Tin cans, aluminum cans, glass jars, PP bottles, and retort pouches.

4. How long does installation take?

Normally 10–25 days depending on the automation level and production capacity.

5. Do you provide turnkey solutions for new factories?

Yes. We offer layout design, process planning, equipment selection, installation, training, and long-term service.

6. Are spare parts easy to get?

Common components use international brands, convenient for global replacement and maintenance.

Call to Action

Contact us for a complete turnkey proposal, layout drawings, equipment quotation, and technical consultation.

We help you build a modern, efficient, and profitable canned food production plant.

Must-read blogs for bosses