Peach Canned Food Production Line - Chinese Manufacturer, Factory, Supplier

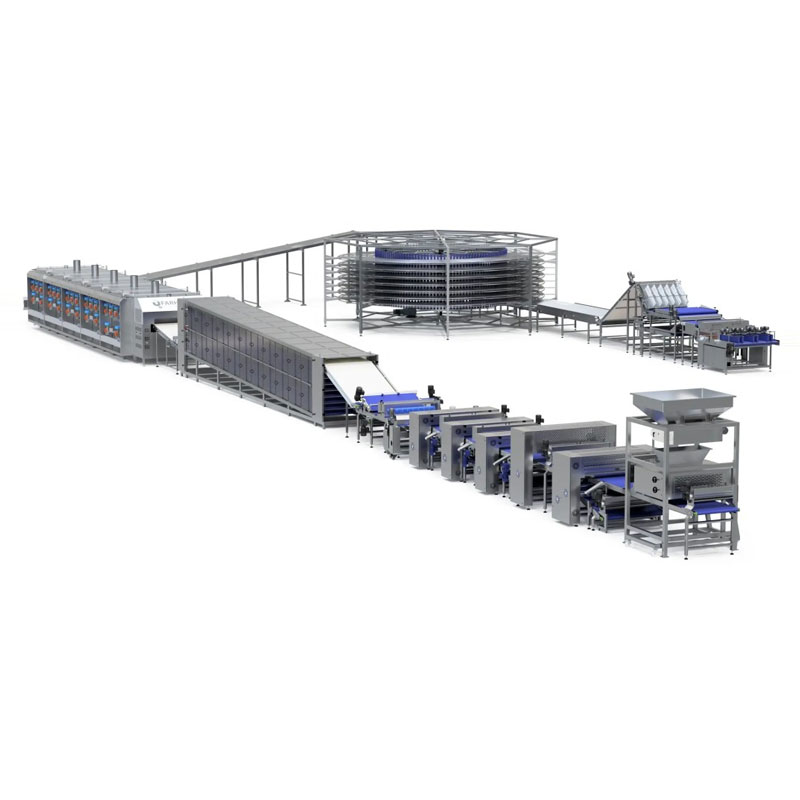

The peach Canned Food Production Line is a specialized system designed to process fresh peaches into high-quality, shelf-stable canned products. It integrates advanced automation with rigorous food safety standards, ensuring efficiency, consistency, and product excellence from raw material intake to final packaging.

The process begins with raw peach receiving, sorting, and washing to eliminate impurities. Automated peeling and pitting machines ensure precision and speed, reducing manual labor while preserving fruit integrity. Peaches are then cut into halves, slices, or cubes according to product specifications. Once prepared, the fruit is blanched to maintain color, texture, and nutritional value before moving to filling. Modern filling systems dispense peaches along with syrup, juice, or light brine into cans or jars with high accuracy, ensuring uniform quality across each batch.

After filling, the sealing equipment creates airtight closures, preventing contamination. The sterilization phase, typically conducted with advanced retort technology, ensures microbial safety while preserving the natural sweetness and aroma of the peaches. The final steps—cooling, labeling, and packaging—complete the process, preparing the finished canned peaches for domestic distribution or export.

Flexibility is a key advantage of the peach canned food production line. It accommodates multiple formats, including whole peaches, halves, slices, or fruit cocktails, as well as various packaging types such as tin cans, glass jars, and retort pouches. The modular design allows manufacturers to scale production capacity, catering to both small-scale specialty processors and large industrial producers.

Efficiency and compliance are central to the line’s design. Stainless steel construction ensures hygiene and ease of cleaning, while automated monitoring systems maintain precise control over filling, sealing, and sterilization parameters. Compliance with HACCP, ISO22000, and GMP guarantees that the final product meets stringent global food safety regulations.

With rising consumer demand for convenient, natural, and long-shelf-life fruit products, investing in a peach canned food production line enables manufacturers to capture market growth opportunities, reduce production costs, and enhance competitiveness. By delivering high-quality canned peaches that retain their natural flavor and nutrition, processors can build strong brand credibility and expand into both domestic and international markets.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line SD-3000 / SD-4000 Commercial Cube Ice Maker

SD-3000 / SD-4000 Commercial Cube Ice Maker Canned Fish Production Line

Canned Fish Production Line Pasta Machine

Pasta Machine Pita Production Line

Pita Production Line Cooked Meat Shredder Machine

Cooked Meat Shredder Machine SY-168 / SY-158 Commercial Ice Shaver Machine

SY-168 / SY-158 Commercial Ice Shaver Machine