Automatic Noodle Machine Factory - Chinese Manufacturer, Factory, Supplier

An automatic noodle machine factory specializes in the innovation, engineering, and production of equipment that simplifies large-scale noodle manufacturing. These factories design machines capable of handling every stage of production—dough mixing, sheeting, cutting, steaming, frying, and cooling—with high precision and speed. Automation not only enhances efficiency but also ensures consistent quality across vast output volumes.

Modern automatic noodle machine factory solutions integrate stainless steel construction, advanced temperature controls, and modular systems that adapt to different noodle varieties, including instant, fresh, and dried noodles. Many factories also implement energy-saving technologies, automated oil filtration, and hygienic processing designs that align with international food safety standards such as HACCP and ISO22000.

Clients from food processing plants, instant noodle producers, and commercial kitchens rely on these factories to deliver robust, customizable equipment. By offering turnkey solutions—ranging from single machines to complete production lines—an automatic noodle machine factory becomes a strategic partner in scaling operations, reducing labor costs, and maintaining competitive pricing in global markets.

Through continuous research and development, these factories not only meet today’s demand but also anticipate future trends in healthier, more sustainable, and diversified noodle production.

Lamian Noodles Processing Production Line

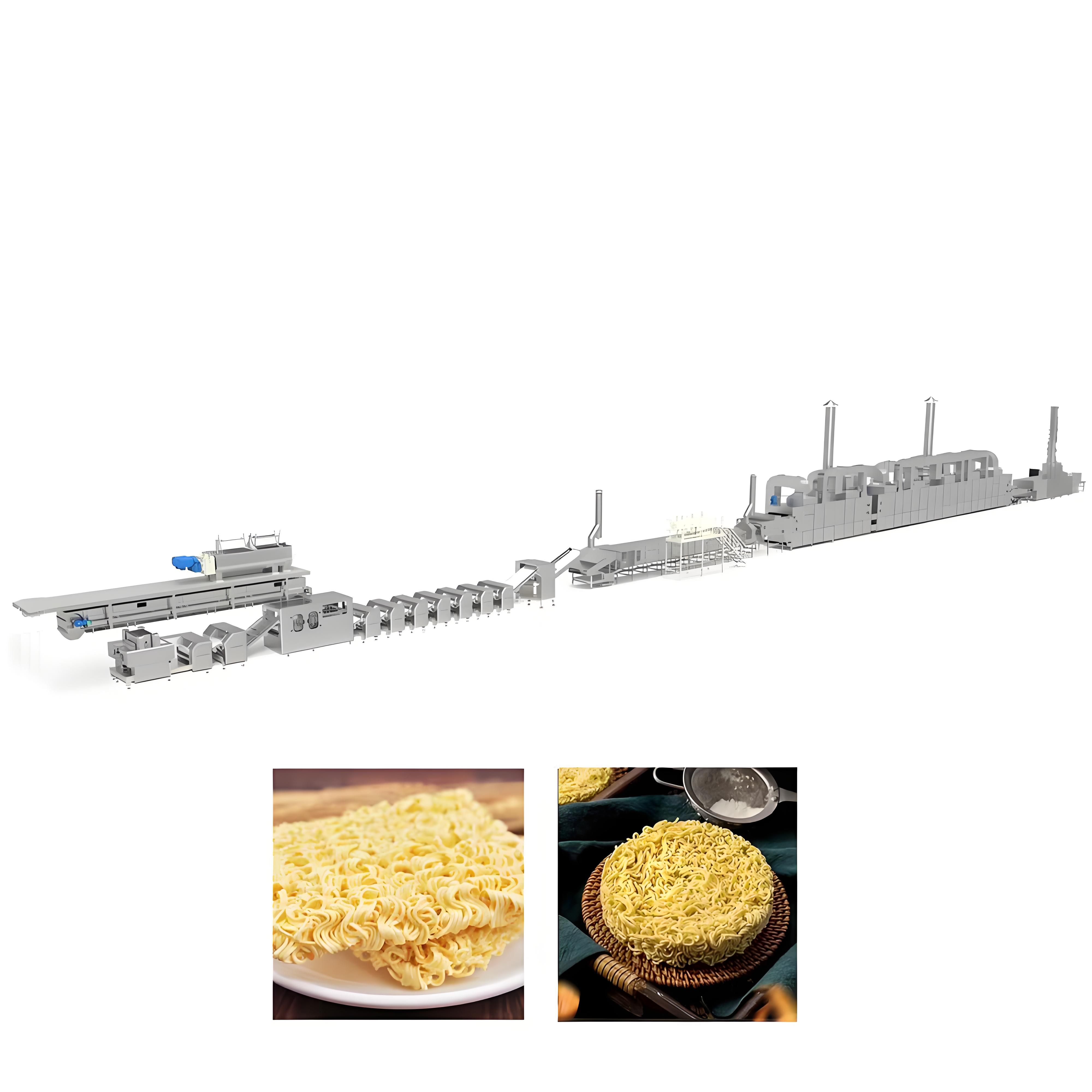

Lamian Noodles Processing Production Line Deep-Fried Instant Noodle Production Line

Deep-Fried Instant Noodle Production Line Automatic Noodle Making Machine

Automatic Noodle Making Machine Multifunctional Noodle Making Machine

Multifunctional Noodle Making Machine Commercial Pasta Sheeter

Commercial Pasta Sheeter Fish Scaler Machine

Fish Scaler Machine Blackfish Canning Production Line

Blackfish Canning Production Line High-Speed Twisting Machine

High-Speed Twisting Machine Model 330 Frequency Conversion High Speed Chopper

Model 330 Frequency Conversion High Speed Chopper Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Canned Beans Production Line

Canned Beans Production Line