Tuna Canned Food Production Line - Chinese Manufacturer, Factory, Supplier

A state-of-the-art Tuna Canned Food Production Line is indispensable for seafood processors aiming to meet global demand with consistency, efficiency, and compliance. Designed to streamline every stage of tuna processing, this integrated system ensures optimal throughput while preserving the nutritional integrity and delicate texture of the fish.

The process begins with automated fish unloading and pre-cleaning, reducing manual labor and ensuring hygienic handling. Precision cutting and portioning modules guarantee uniformity, preparing each tuna segment for subsequent cooking and cooling. These stages are vital to achieving the perfect balance of tenderness and flavor, a benchmark for premium canned tuna.

Once cooked, the Tuna Canned Food Production Line employs advanced filling systems capable of high-speed operations while maintaining exact weight control. Whether in brine, oil, or custom marinades, the filling process is executed with uncompromising accuracy to meet diverse market specifications. Seamless integration with seaming equipment ensures hermetic sealing, safeguarding product quality throughout its shelf life.

Quality assurance remains central to this production solution. Inline inspection technologies, including X-ray detection and vision-based monitoring, identify any anomalies in real time, minimizing wastage and upholding safety standards. Coupled with CIP (Clean-in-Place) systems, the entire line adheres to the most stringent hygiene protocols demanded by international regulatory bodies.

From small-scale enterprises to industrial-scale factories, a Tuna Canned Food Production Line provides scalability and adaptability, offering configurations tailored to production capacity and product variety. It not only enhances operational efficiency but also supports sustainability initiatives by optimizing resource usage and reducing energy consumption.

Investing in a modern Tuna Canned Food Production Line empowers seafood processors to remain competitive in a dynamic market while delivering superior products that satisfy consumer expectations for quality, safety, and taste.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Honey Processing Equipment

Honey Processing Equipment Fish Deboner Machine

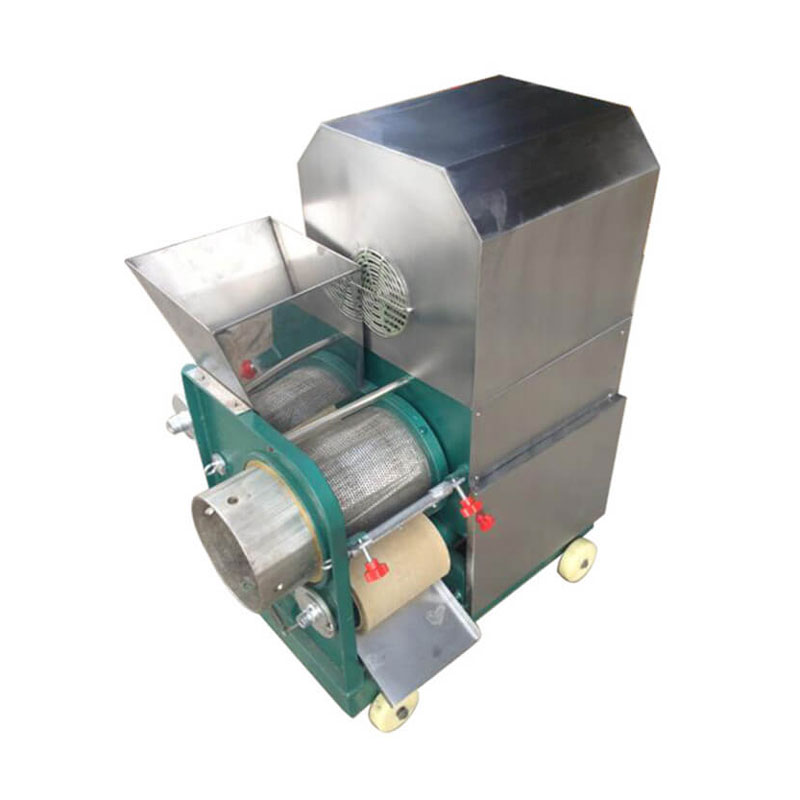

Fish Deboner Machine Gummy Candy Production Line

Gummy Candy Production Line Cold Chain Rice Production Line

Cold Chain Rice Production Line Cucumber Canning Production Line

Cucumber Canning Production Line Chicken Feet Peeling Production Line

Chicken Feet Peeling Production Line Industrial Microwave Drying Machine

Industrial Microwave Drying Machine