1. Overview

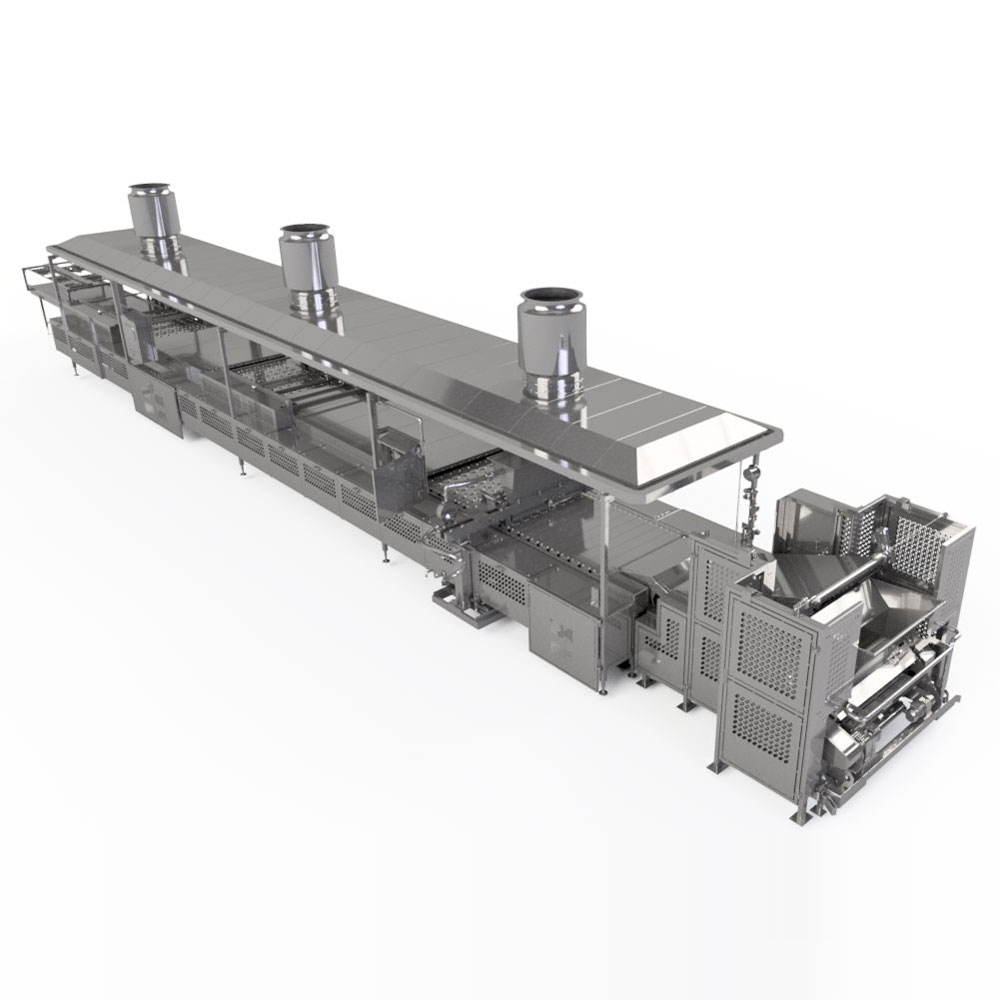

The Pancake Production Line is a fully automatic system designed for the large-scale production of pancakes, crepes, and similar bakery-style breakfast products.

This line combines batter preparation, automatic dosing, baking, turning, cooling, and packaging into a single streamlined process.

It is ideal for food processing plants, central kitchens, and frozen bakery manufacturers looking to ensure consistent product quality, reduce labor costs, and increase production efficiency.

2. Production Capacity

| Model | Output Range | Pancake Size | Application |

|---|---|---|---|

| PL-200 | 1,000–2,000 pcs/h | 80–100 mm | Small bakeries / test lines |

| PL-500 | 3,000–5,000 pcs/h | 100–150 mm | Mid-scale factories |

| PL-1000 | 8,000–10,000 pcs/h | 100–200 mm | Industrial pancake producers |

(Customized sizes, shapes, and patterns available upon request.)

3. Process Flow

Batter Mixing

Automated mixing of flour, eggs, milk, sugar, and additives to form a smooth, uniform batter.Batter Feeding & Dosing

Precision dosing system pours batter onto the baking plates with accurate volume control.Continuous Baking

Pancakes are baked on a rotary or tunnel-type oven with adjustable temperature zones.Automatic Turning (optional)

For double-sided pancakes, an automatic flipping device ensures uniform browning.Cooling & Stacking

Cooled by air conveyors; pancakes are automatically stacked and aligned.Packaging

Integrated flow wrapping or vacuum packaging machine seals the final products for freshness.

4. Main Equipment Configuration

| Equipment | Function | Technical Highlights |

|---|---|---|

| Batter Mixing Tank | Prepare batter | SUS304 tank, variable-speed agitator |

| Dosing Pump | Batter portioning | Servo control, precise dosing volume |

| Baking Machine | Heat treatment | Electric / gas heating, temperature 160–220°C |

| Conveyor System | Product transfer | Food-grade belts, adjustable speed |

| Cooling Conveyor | Temperature reduction | Stainless frame, gentle air circulation |

| Stacking Unit | Automatic collection | Pneumatic lifter, adjustable height |

| Packaging Machine | Final sealing | Flow-wrap or vacuum options |

5. Technical Features

Full Automation: From raw batter to packed pancake, reducing labor by up to 70%.

Energy Efficiency: Intelligent temperature control minimizes heat loss.

Hygienic Design: All food-contact parts are SUS304 stainless steel, easy to clean and maintain.

Customizable Size & Shape: Supports round, oval, heart-shaped, or rectangular pancakes.

Consistent Product Quality: Even baking color and uniform thickness.

Flexible Heating Options: Electric, gas, or infrared according to factory setup.

PLC & Touchscreen Control: Easy recipe management and production monitoring.

6. Optional Modules

Syrup or butter filling machine (for flavored pancakes)

Cooling tunnel with humidity control

Metal detector and weight checker

Automatic tray loading system

Stacking and counting robot arm

Nitrogen flushing packaging machine

7. Technical Specifications (Example: PL-500 Line)

| Item | Specification |

|---|---|

| Capacity | 3,000–5,000 pcs/hour |

| Pancake Size | 100–150 mm diameter |

| Heating Method | Gas / Electric |

| Total Power | 45 kW |

| Line Length | 12–18 m |

| Material | SUS304 stainless steel |

| Voltage | 380V, 50Hz (customizable) |

| Control System | Siemens PLC + HMI |

| Operating Temperature | 160–220°C |

| Automation Level | Fully automatic |

8. Application Scope

Ready-to-eat pancakes

Frozen pancakes and crepes

Filled or stuffed pancakes

School and airline catering products

Industrial bakery OEM production

9. Advantages

✅ High Productivity: Continuous operation suitable for mass production.

✅ Stable Quality: Precise dosing and even heating ensure consistent taste.

✅ Energy Saving: Multi-zone heating and heat recovery system reduce gas/electric consumption.

✅ Low Maintenance: Durable components, simple operation, and quick cleaning.

✅ Customizable Recipes: Compatible with various batters — plain, sweet, or savory.

✅ Compliant with Food Standards: CE / ISO9001 / HACCP certified.

10. ROI & Performance

Labor Reduction: Up to 60% vs. manual production.

Waste Rate: <1% batter loss.

Energy Saving: 15–25% lower energy cost with insulated baking chambers.

ROI Period: 12–18 months for mid-size facilities.

11. Layout & Engineering Service

We offer turnkey factory layout design including space optimization, material flow, power, and exhaust planning.

Custom 2D/3D CAD layouts can be provided according to plant size and production targets.

12. After-Sales Support

On-site installation and commissioning

Operator training & maintenance guide

Spare parts supply

24/7 online technical support

Remote monitoring and recipe update service

13. Summary

The Automatic Pancake Production Line provides a reliable, hygienic, and energy-efficient solution for high-volume pancake and crepe production.

Its modular design allows flexibility in product variety and output scale, making it the perfect investment for food manufacturers aiming for efficiency, consistency, and long-term profitability.

Must-read blogs for bosses