Big Pasta Machine Manufacturer - Chinese Manufacturer, Factory, Supplier

A big pasta machine manufacturer plays a crucial role in supporting the global food industry by delivering large-scale, high-capacity equipment that transforms raw ingredients into premium-quality pasta. Unlike small-scale producers, these manufacturers focus on industrial solutions designed for continuous operation, high efficiency, and strict compliance with international food safety standards. Their machines are not only robust and durable but also engineered to optimize every stage of pasta production—from dough mixing to shaping, drying, and even integrated packaging.

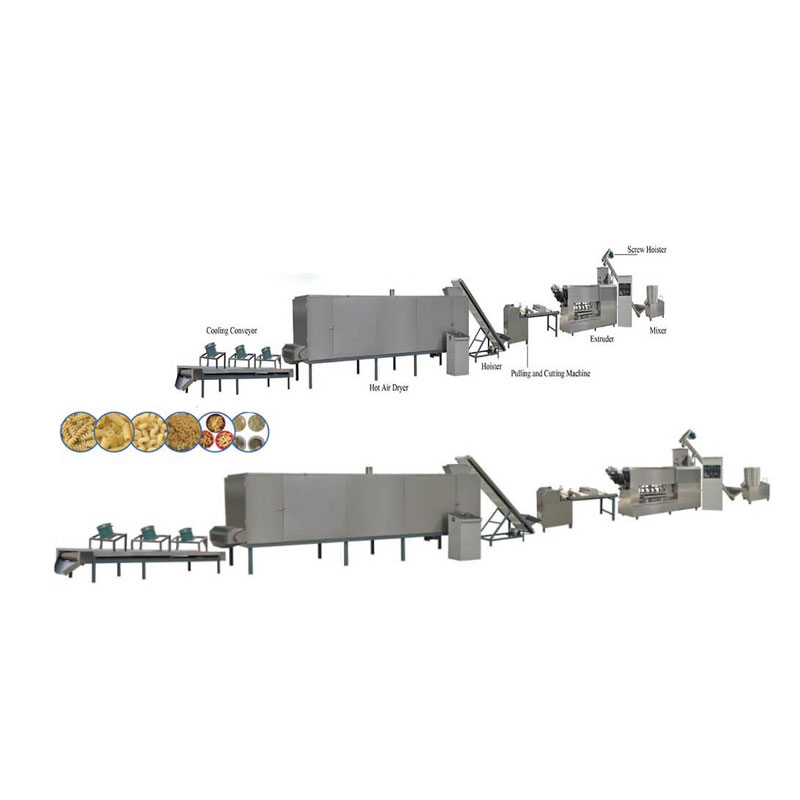

What distinguishes a big pasta machine manufacturer is the scale of production capacity they can provide. Their equipment is capable of processing hundreds to thousands of kilograms of pasta per hour, making them ideal partners for commercial food factories and global brands. By leveraging automation and advanced extrusion systems, these manufacturers ensure consistency in pasta texture, uniformity in shapes, and reduced production downtime. Whether producing long-cut pasta such as spaghetti and linguine, or short-cut varieties like penne and fusilli, the machines guarantee reliability and repeatability at industrial volumes.

Hygiene and compliance are at the forefront of these manufacturers’ priorities. Machines are typically constructed from food-grade stainless steel and designed with easy-to-clean components, ensuring alignment with HACCP, ISO, and GMP standards. Features like temperature control, automated drying chambers, and precise dosing systems contribute to product safety and shelf stability. For global food processors, this compliance offers peace of mind and smooth access to regulated markets.

Customization is another hallmark of a big pasta machine manufacturer. Businesses can choose configurations tailored to their specific needs—such as output capacity, pasta shapes, energy efficiency levels, and integration with existing production lines. Some manufacturers even provide turnkey solutions, from raw ingredient handling to finished packaging, enabling food companies to streamline their operations under one supplier.

Beyond machinery, these manufacturers provide comprehensive support, including installation, staff training, and technical servicing. With international logistics networks and spare parts availability, they ensure minimal downtime and long-term return on investment for their clients. For food enterprises looking to expand production, reduce costs, and deliver consistent pasta quality, collaborating with a big pasta machine manufacturer is a strategic step toward sustainable growth.

Ultimately, these manufacturers empower pasta producers to scale operations confidently, meet global demand, and maintain competitiveness in an evolving international market. Their machines embody innovation, efficiency, and durability—cornerstones of success in the modern food processing industry.

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Production Line

Pasta Production Line Pasta Machine

Pasta Machine Pasta /Macaroni Making Line

Pasta /Macaroni Making Line Multifunction Pasta Machine

Multifunction Pasta Machine Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Pet Canned Food Production Line

Pet Canned Food Production Line Automatic Fresh Meat Dicing Machine

Automatic Fresh Meat Dicing Machine Donut Making Machine

Donut Making Machine Meat Cuber Machine

Meat Cuber Machine Bean Product Production Line

Bean Product Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Automatic Chicken Cutting Machine

Automatic Chicken Cutting Machine