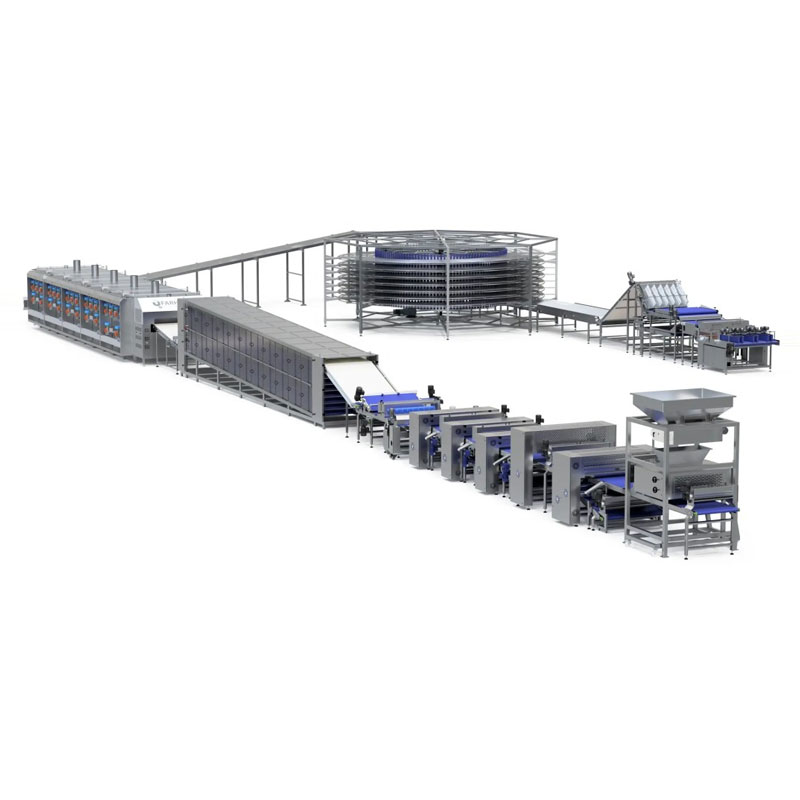

Our Pita Production Line is a fully automated, high-efficiency production system designed for commercial bakeries and food manufacturers producing pita bread at scale. From dough preparation to final baking and cooling, every step is engineered for consistent quality, minimized labor, and maximum productivity. Whether you're supplying retail chains, food service providers, or frozen bakery distributors, our pita line ensures perfect roundness, puffing, and texture—batch after batch.

Key Features

Fully Integrated Process

Includes dough mixing, sheeting, resting, forming, proofing, baking, cooling, and optional packaging modules.High-Speed Performance

Supports output capacities from 2,000 to 12,000 pieces/hour, suitable for medium to large-scale operations.Consistent Quality Control

Automated portioning and pressing ensure uniform thickness, diameter (typically 10–20 cm), and moisture content.Customizable Layout

Modular design allows customization based on factory space, required capacity, and product specifications.Energy-Efficient Oven Systems

Stone plate or tunnel ovens with precision temperature controls for even puffing and optimal bake texture.Multi-Product Flexibility

Adaptable for pita, naan, tortilla, lavash, and other flatbread types with minor tooling adjustments.

Technical Specifications (Typical Model)

| Component | Description |

|---|---|

| Dough Mixer | 100–300kg/batch spiral or planetary mixers |

| Dough Divider & Rounder | Servo-controlled precision division |

| Dough Resting Conveyor | Gentle resting for gluten relaxation |

| Sheeter & Press | Adjustable thickness from 2–8 mm |

| Proofer (optional) | Enclosed chamber with humidity & temp control |

| Tunnel Oven | 3–5 zone baking with top & bottom heat control |

| Cooling Conveyor | Stainless steel, 10–20 minutes cooling |

| Output Capacity | 2,000 – 12,000 pcs/hour (customizable) |

| Power Requirement | Approx. 80–150kW depending on configuration |

| Line Footprint | 15–30 meters length (customized layout available) |

Advantages for Industrial Bakeries

✅ Labor Savings: Reduces manual handling and increases consistency

✅ Fast ROI: High throughput and low defect rates accelerate investment recovery

✅ Food Safety Compliance: Built with food-grade stainless steel and CE/UL certified components

✅ Easy Maintenance: Modular design with tool-free cleaning access and minimal downtime

✅ Global Support: Installation, training, and after-sales service available worldwide

Applications

Commercial bread factories

Frozen food manufacturers

HORECA suppliers

Private label bakery brands

Middle Eastern and Mediterranean food processors

Optional Add-ons

Automatic Packaging Systems (flow wrap, MAP)

Vision Inspection Systems

Recipe Management Software

Remote Monitoring & Diagnostics Module

Gluten-Free or Wholegrain Dough Adaptation

Why Choose Us?

With over 15 years of experience in food processing automation, we offer turnkey pita bread solutions backed by engineering expertise, rapid customization, and responsive global service. Whether you are upgrading an existing line or setting up a new facility, our pita production systems are built to grow with your business.

📩 Request a Quote Today

Contact our sales team to get a custom layout, pricing, and ROI analysis tailored to your production needs.

Must-read blogs for bosses