Imported Canned Fish Production Line - Chinese Manufacturer, Factory, Supplier

The Imported Canned Fish Production Line is a comprehensive industrial system designed for the automated processing, filling, sealing, and sterilization of various imported fish species such as tuna, mackerel, sardine, and salmon. This production line integrates advanced automation control technology, high-precision weighing systems, and hygienic stainless steel construction to ensure the final canned products meet international food safety and export standards. It is ideal for seafood canning factories, fishery processing plants, and import-export enterprises seeking high efficiency, consistent product quality, and strong market competitiveness.

The entire line typically includes key sections such as raw material cleaning and grading, cutting and precooking, filling and weighing, can washing, automatic sealing, vacuum exhaust, sterilization and cooling, and labeling and packaging. Each unit is designed to minimize manual labor while maximizing production output and traceability. Optional modules such as automatic fish meat separators, oil or brine filling systems, and CIP (Clean-in-Place) sanitation systems can be customized according to production requirements and capacity levels.

With the increasing global demand for imported canned fish due to convenience and nutrition, this production line ensures not only efficiency but also compliance with HACCP, ISO22000, and FDA standards. The equipment adopts food-grade stainless steel materials, corrosion-resistant design, and energy-saving heating systems, ensuring long-term stability and low maintenance costs.

Our Imported Canned Fish Production Line supports production capacities ranging from small-scale batches to fully automated large-scale systems. Whether you are a seafood processing factory upgrading your current canning line or a new investor entering the canned fish market, this system offers an ideal balance of cost-effectiveness, hygiene, and automation to enhance productivity and meet export market requirements.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

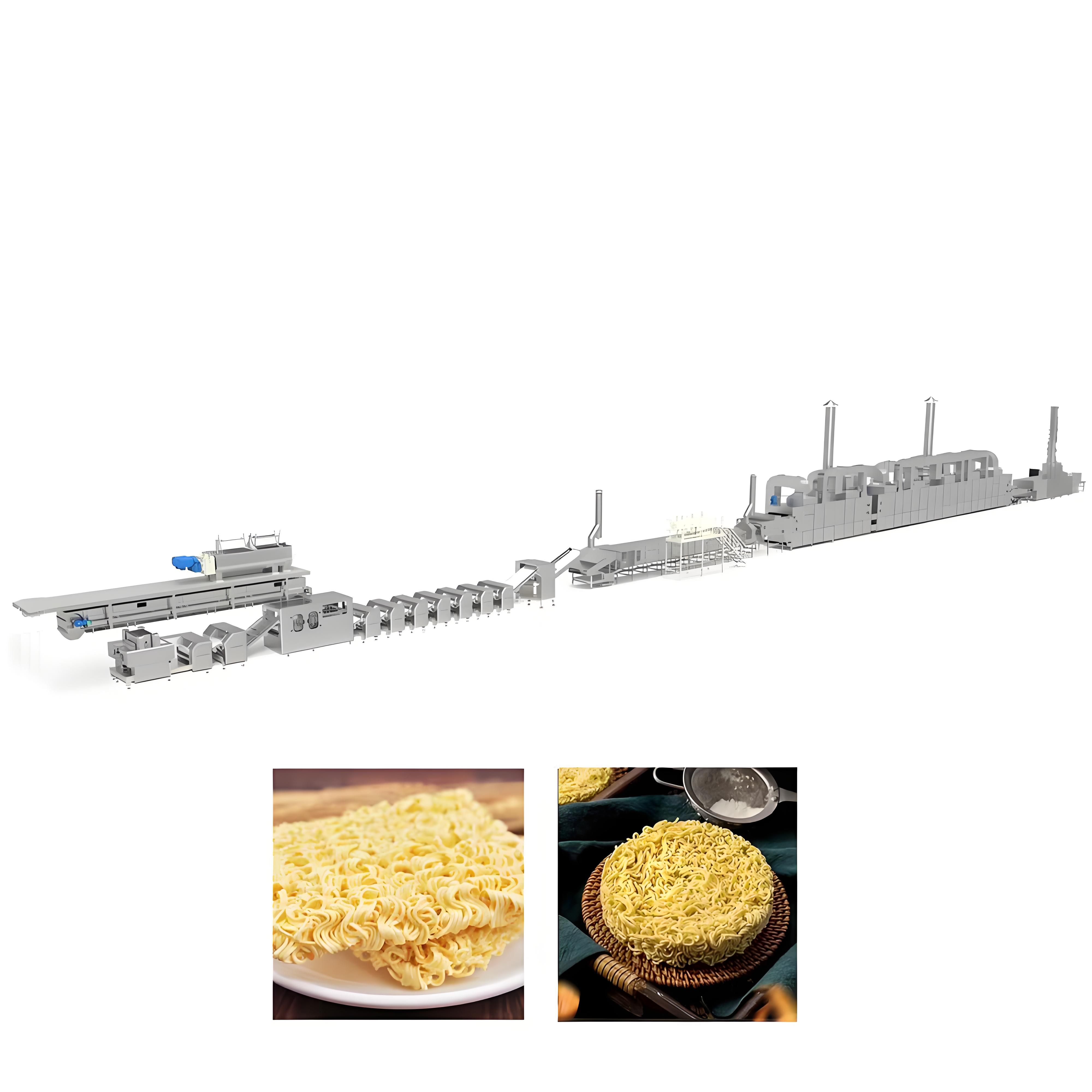

Fruit And Vegetable Canned Production Line Deep-Fried Instant Noodle Production Line

Deep-Fried Instant Noodle Production Line Honey Processing Equipment

Honey Processing Equipment Double-Wok Dual-Temperature Induction Cooker

Double-Wok Dual-Temperature Induction Cooker SD-3000 / SD-4000 Commercial Cube Ice Maker

SD-3000 / SD-4000 Commercial Cube Ice Maker Meat Pie Maker Machine

Meat Pie Maker Machine Double-Door Sterilizer

Double-Door Sterilizer Cooked Meat Shredder Machine

Cooked Meat Shredder Machine