Ice Cream Production Line - Chinese Manufacturer, Factory, Supplier

An ice cream production line is a fully automated system designed to produce a wide range of frozen desserts efficiently and consistently, while maintaining the highest food safety standards. With global consumption of ice cream growing steadily, manufacturers are increasingly adopting these lines to meet market demand for high-quality, flavorful, and visually appealing frozen products.

The process begins with raw material preparation, where milk, cream, sugar, stabilizers, emulsifiers, and flavorings are precisely measured and mixed. Automated dosing and blending systems ensure uniform consistency across every batch, providing a reliable foundation for texture, creaminess, and taste.

Next, the mixture undergoes pasteurization and homogenization. Pasteurization eliminates harmful microorganisms, while homogenization breaks down fat molecules to create a smooth, stable texture. PLC-controlled systems allow precise regulation of temperature, pressure, and processing time, ensuring consistent quality and food safety compliance.

Following pasteurization, the ice cream base enters aging tanks, where it is cooled and stabilized for several hours. Aging improves viscosity and whipping properties, preparing the mix for freezing. Continuous freezers then convert the base into soft or hard ice cream by incorporating air (overrun) and achieving the desired density. Some advanced lines also feature flavor injection or inclusions systems, allowing the addition of chocolate chips, nuts, fruit pieces, or sauce swirls during freezing.

The frozen product is then directed to automated packaging systems, which handle cups, tubs, cones, or multi-pack cartons. These systems include filling, sealing, labeling, and coding, ensuring hygiene, efficiency, and a professional appearance. Large-scale lines may also integrate with cold storage and conveyor systems to maintain product integrity until distribution.

Applications for ice cream production lines are broad, including soft-serve ice cream, hard scoop ice cream, gelato, frozen yogurt, and novelty products. The lines are highly customizable, with options for varying production capacities, product types, and packaging formats. This flexibility makes them suitable for both small artisan manufacturers and large industrial producers.

Investing in an ice cream production line provides multiple advantages: increased production efficiency, consistent product quality, reduced labor costs, and compliance with international standards such as HACCP, ISO, and CE. With the ability to scale production and diversify product offerings, these lines enable manufacturers to meet consumer demand, stay competitive in global markets, and ensure long-term profitability.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Fish Slicer Machine

Fish Slicer Machine AF Series Flake Pellet Ice Machine

AF Series Flake Pellet Ice Machine SC Series Bullet Ice Maker

SC Series Bullet Ice Maker SF Series Snowflake Ice Machine

SF Series Snowflake Ice Machine AP Series Flake Ice Machine

AP Series Flake Ice Machine SY-168 / SY-158 Commercial Ice Shaver Machine

SY-168 / SY-158 Commercial Ice Shaver Machine AM Series Crescent Ice Maker

AM Series Crescent Ice Maker Honey Processing Equipment

Honey Processing Equipment Multifunctional Noodle Making Machine

Multifunctional Noodle Making Machine Chicken Slaughtering Machine

Chicken Slaughtering Machine Automatic Meatball Making Machine

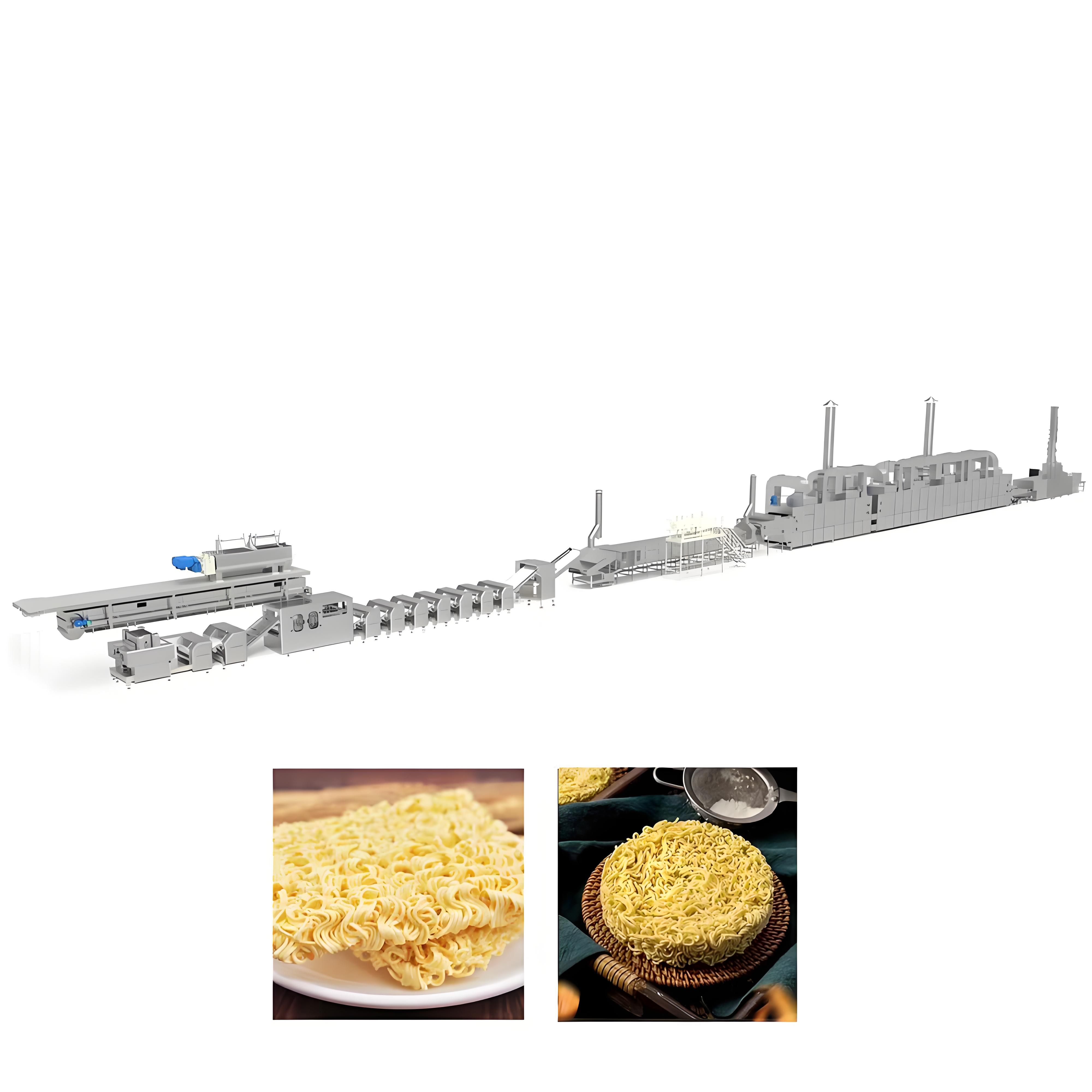

Automatic Meatball Making Machine Deep-Fried Instant Noodle Production Line

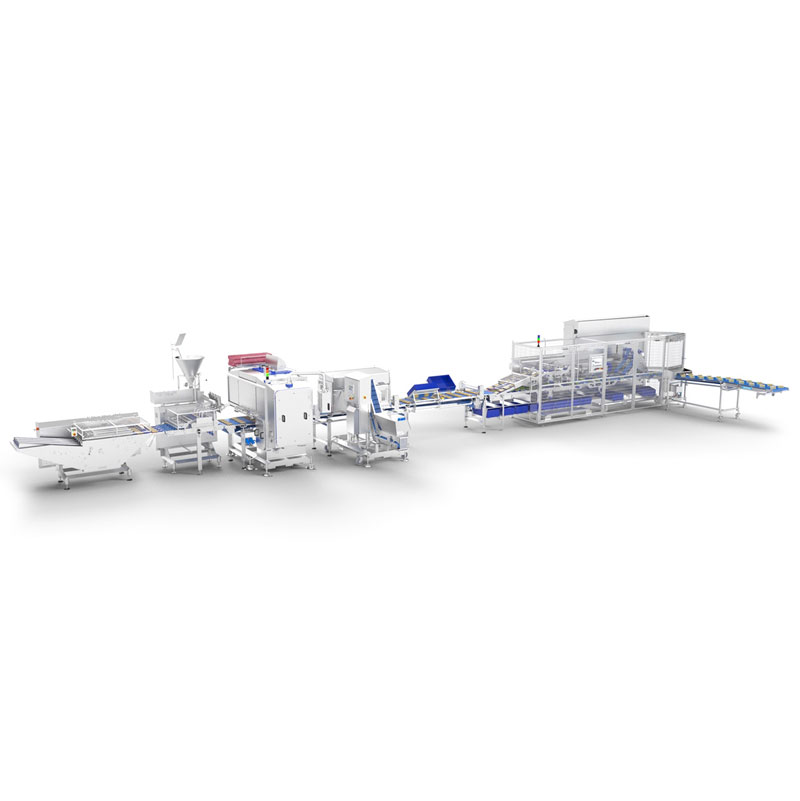

Deep-Fried Instant Noodle Production Line Sandwich Production Line

Sandwich Production Line Tomato Sauce Grinding Machine

Tomato Sauce Grinding Machine