1. Overview

The Spinach Canned Food Production Line is designed for industrial-scale processing of spinach and leafy greens, delivering high-quality canned products efficiently and safely. It is suitable for canned vegetable manufacturers, food processing factories, and exporters targeting international markets.

Key highlights for B2B decision-makers:

Fully automatic or semi-automatic configurations

High production capacity: 1,500–10,000 cans/hour depending on model

Compliance with HACCP, ISO22000, and GMP standards

Modular design for easy upgrading, maintenance, and production flexibility

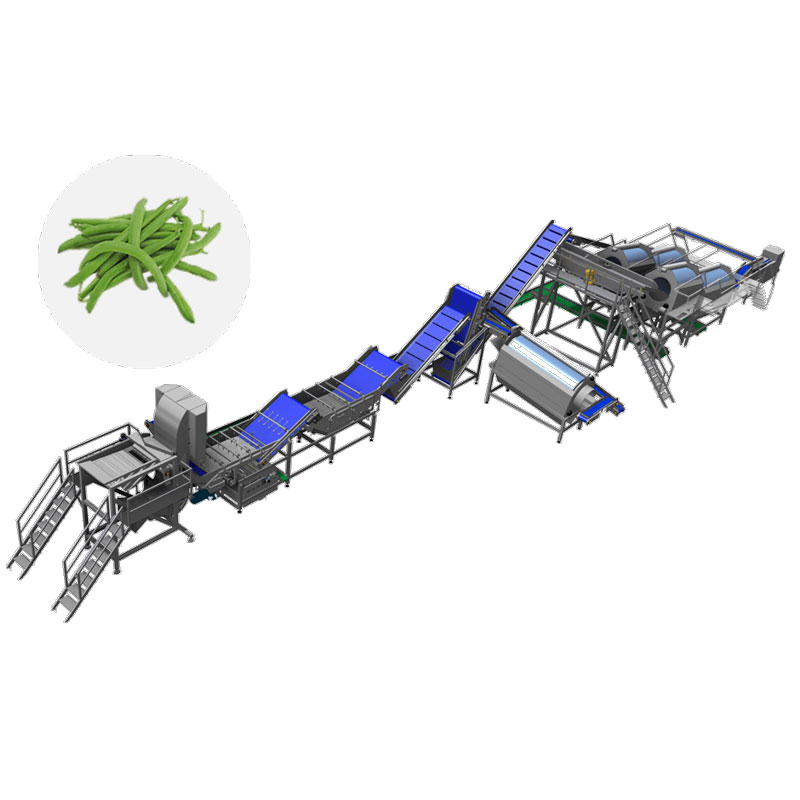

2. Production Flow & Key Equipment

Step 1: Raw Material Receiving & Storage

Fresh spinach is received and stored in temperature-controlled areas to maintain freshness.

Pre-sorting removes damaged or wilted leaves.

Step 2: Washing & Cleaning

Automatic washing machines remove soil, impurities, and pesticide residues.

Multi-stage water recycling system reduces water consumption.

Step 3: Blanching

Continuous or batch blanching with hot water or steam.

Inactivates enzymes, improves color, texture, and preserves nutrients.

Adjustable time and temperature based on spinach weight and can size.

Step 4: Cutting / Portioning

Optional leaf cutting or portioning machines for uniform can filling.

Ensures consistent texture and portion sizes.

Step 5: Filling

Automatic can filling machines portion spinach accurately into cans.

Filling accuracy: ±5 g to minimize waste.

Step 6: Brine or Sauce Addition

Precise dosing of brine, salt, or vegetable sauces.

Supports multiple product variants: plain, seasoned, or mixed vegetable spinach cans.

Step 7: Can Seaming

Automatic seaming machines ensure hermetic sealing to prevent leakage.

Seaming quality meets international export standards.

Step 8: Sterilization

Retort sterilizers provide shelf-stable products.

Programmable sterilization profiles optimize product safety and texture.

Step 9: Cooling & Drying

Rapid cooling preserves green color and nutrients.

Air-drying conveyors prepare cans for labeling and packaging.

Step 10: Labeling & Packaging

Automatic labeling ensures consistent branding and traceability.

Optional shrink wrapping or carton packing for efficient logistics.

3. Technical Advantages

| Feature | Advantage |

|---|---|

| Fully automated line | Reduces labor costs by up to 60%, ensures product consistency |

| Modular design | Easy expansion and integration of new technologies |

| Water & energy saving | Closed-loop systems reduce operational costs |

| Quality control integration | Inline metal detectors, weight checkers, and inspection stations |

| Flexible product types | Supports plain spinach, seasoned spinach, or mixed vegetable cans |

4. ROI & Investment Considerations

High efficiency: Production lines can achieve 1,500–10,000 cans/hour depending on configuration.

Reduced labor costs: Automation lowers operational expenses.

Long-term durability: Stainless steel contact parts and advanced control systems minimize downtime.

Global compliance: Equipment meets export standards, opening international market opportunities.

Tip for investors: Evaluate ROI by considering equipment cost, labor savings, production output, and market price per can. Automated lines often recover investment within 2–3 years in high-volume operations.

5. Food Safety & Quality Control

All contact parts are food-grade stainless steel.

CIP (clean-in-place) systems ensure hygiene between batches.

Compliance with HACCP, ISO22000, and GMP standards.

Optional tracking system for full traceability from raw spinach to finished cans.

6. Optional Customizations

Flavor options: Garlic, olive oil, mixed vegetable spinach cans.

Can sizes: 100 g, 155 g, 200 g, 425 g.

Automation levels: Semi-automatic for small enterprises; fully automatic for large-scale production.

Packaging options: Shrink-wrapped cartons, bulk logistics solutions.

Summary

The Spinach Canned Food Production Line is a high-efficiency, reliable, and food-safe solution for industrial canned vegetable production. It is ideal for B2B customers seeking to optimize production, reduce labor costs, and produce high-quality canned spinach suitable for international markets.

Must-read blogs for bosses