Home >

Related Products

Core Competitive Advantages

Technical Leadership & Customer Value Creation Capabilities

Technology Leadership

· 57 core patents in dynamic cutting algorithms & IoT control

· 8.5% R&D investment ratio with 3-5 new models annually

Agile Supply Chain

· 82% vertical integration of critical components

· 40% inventory turnover improvement via digital systems

Full-Lifecycle Service

· 25% lower TCO for equipment lifecycle

· 24/7 remote diagnostics support

· >95% client retention over 5 years

Green Compliance

· 35% energy consumption reduction

· Certified by CE/FDA/ISO 14064

· ≥92% material recyclability

Project Case

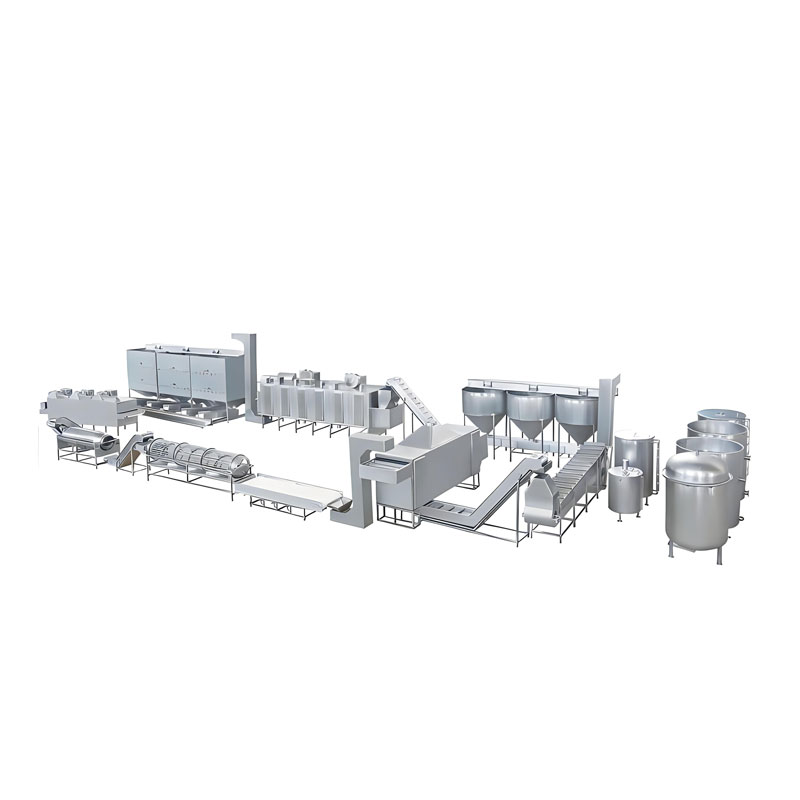

Learn about our efficient and reliable equipment and production line solutions tailored for various food processing industries.

Commercial Kitchen Equipment

Snack Food Processing Equipment

Fruit and Vegetable Processing Equipment

Meat Processing Equipment

Bakery & Cereal Processing Equipment

Seafood Processing Equipment

Dairy Processing Equipment

Seasoning & Sauce Processing Equipment

Cosmetics Processing Equipment

Pet Food Processing Equipment

Ready Meal Processing Equipment

Beer and Beverage Processing Equipment

Relevant News

How Much Does a Luncheon Meat Canning Production Line Cost?

1. Introduction: Why Luncheon Meat Canning Lines Are in High DemandThe global demand for luncheon meat has been steadily increasing thanks to modern consumers’ ...

How Much Does a Meat Canning Production Line Cost?

1. Introduction: The Growing Market for Canned MeatThe global canned meat industry has been growing rapidly due to rising demand for ready-to-eat protein produc...

Where to Purchase a Meat Grinder – Complete Buyer’s Guide

Purchasing a meat grinder is an important investment whether you’re outfitting a professional kitchen, butcher shop, or simply upgrading your home cooking tools...

Top Rated Commercial Meat Grinders 2025 | Best Heavy Duty Models for Butchers & Processors

Introduction – Why “Top Rated” Matters in Commercial Meat GrindingIn the competitive world of food service and meat processing, efficiency, consistency, and pro...

Top Commercial Meat Processing Equipment Manufacturers in China

China has become one of the world's leading hubs for manufacturing commercial meat processing equipment. With its strong industrial infrastructure, cost-eff...

Best Commercial Meat Grinders of 2025 | Professional Buying Guide

IntroductionChoosing the right commercial meat grinder is crucial for any meat processing business. Whether you run a small butcher shop, supermarket, or large-...

Frozen Food Production Line Solutions: Efficient and High-Quality Processing

Frozen food has become a staple in global diets, driven by consumer demand for convenience and longer shelf life. To meet this demand, manufacturers are investi...

How A Frozen Food Company Achieved A 200% Capacity Increase Through A Customized Production Line

In today's fiercely competitive food processing industry, capacity, operational efficiency, and consistent product quality are essential factors that determ...

Meat Processing Line Solutions for Automated Pork, Beef, and Lamb Cutting & Packaging

In today's meat processing industry, rising consumer demand for quality, hygiene, consistency, and reliable supply is driving a fundamental shift. The tradi...

Customized Dicing Machines: Tailored Solutions for Your Unique Processing Needs

Standard Dicing Machines ≠ One-Size-Fits-All for Every BusinessAs the food processing industry evolves, product types, processing standards, and factory environ...

How Industrial Dicing Machines Transform Your Processing Workflow

The Efficiency Dilemma in the Food Processing IndustryIn recent years, the global food processing industry has been undergoing a profound transformation. Consum...

Common Faults And Solutions Of Meat Dicing Machine

Don't Let Downtime Dice Your Profits: A Troubleshooting GuideYour meat dicer is a cornerstone of efficiency in your operation, consistently delivering unifo...

Meat Canned Food Production Line

Meat Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line French Fries Cutting Machine

French Fries Cutting Machine Fully Automatic Meat Can Production Lines

Fully Automatic Meat Can Production Lines Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Frozen Food Production Line

Frozen Food Production Line Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Model 200 Frequency Conversion High Speed Chopper

Model 200 Frequency Conversion High Speed Chopper Gizzard Peeling Machine

Gizzard Peeling Machine Kimchi Production Line

Kimchi Production Line Mango Juice Processing Production Line

Mango Juice Processing Production Line Lamian Noodles Processing Production Line

Lamian Noodles Processing Production Line Small Scale Banana Chips Production Line

Small Scale Banana Chips Production Line Fish Speed Cleaning Machine

Fish Speed Cleaning Machine