Chicken Meat Tumbler Machine Manufacturer - Chinese Manufacturer, Factory, Supplier

At our Chicken Meat Tumbler Machine Manufacturing facility, we specialize in creating machines that redefine poultry marination and texture enhancement through scientifically optimized tumbling processes. Understanding the delicate structure of chicken meat, our equipment is engineered to maximize marinade uptake while preserving muscle integrity and moisture content.

What sets our tumblers apart is the integration of adjustable rotation speeds combined with programmable tumbling cycles, enabling processors to tailor treatments for different chicken cuts and recipe requirements. This fine control ensures consistent texture, juiciness, and flavor distribution, minimizing product variability and enhancing consumer satisfaction.

Our machines feature a vibration-damping frame and noise reduction technology, designed for quiet operation and extended service life even under continuous, high-volume use. The construction uses high-quality, corrosion-resistant stainless steel with sealed bearings, allowing for aggressive cleaning protocols without compromising durability.

We offer flexible capacity options ranging from small batch tumblers perfect for artisanal producers to large-scale vacuum tumblers suited for industrial poultry processors seeking faster marinade penetration and improved product yield. Our custom solutions can be integrated smoothly with downstream processes, including stuffing, packaging, and cooking lines.

Beyond manufacturing, our commitment extends to comprehensive after-sales support — including onsite commissioning, customized operator training, preventive maintenance scheduling, and rapid spare parts availability — helping your production maintain peak performance.

If your goal is to elevate poultry product quality while optimizing processing efficiency, our precision-engineered chicken meat tumblers provide the technological edge you need. Contact us today to discuss how we can tailor a tumbling solution to your unique production goals.

Meat Canned Food Production Line

Meat Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Automatic Chicken Canned Food Production Line

Automatic Chicken Canned Food Production Line Fully Automatic Meat Can Production Lines

Fully Automatic Meat Can Production Lines Heavy Duty Commercial Meat Grinder

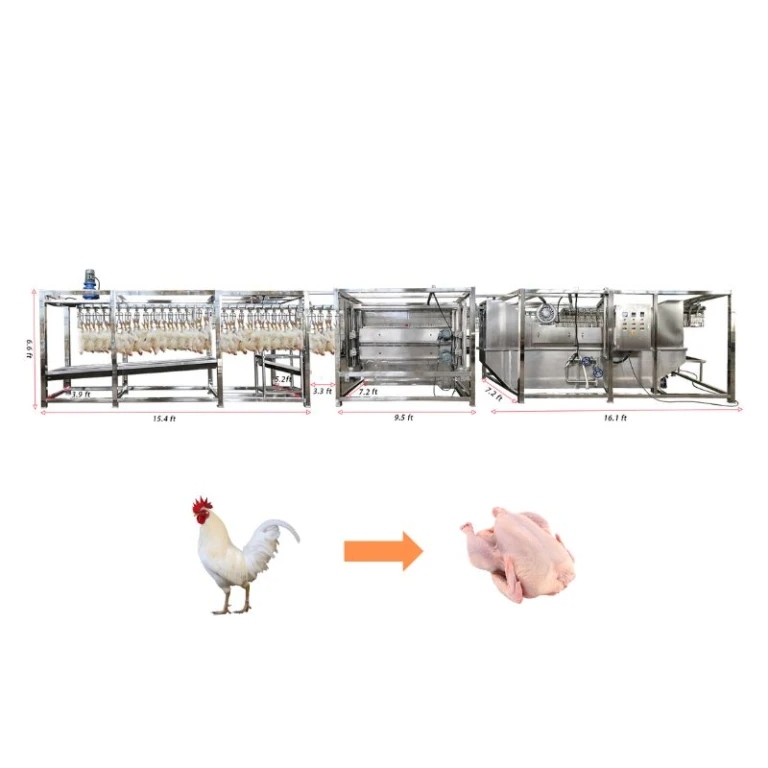

Heavy Duty Commercial Meat Grinder Chicken Production Line

Chicken Production Line Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Centrifugal Dewatering Machine

Centrifugal Dewatering Machine Apple Canning Production Line

Apple Canning Production Line YL-980 Digital Metal Detector

YL-980 Digital Metal Detector Dairy Processing Lines

Dairy Processing Lines Pancake Production Line

Pancake Production Line French Fries Frying Machine

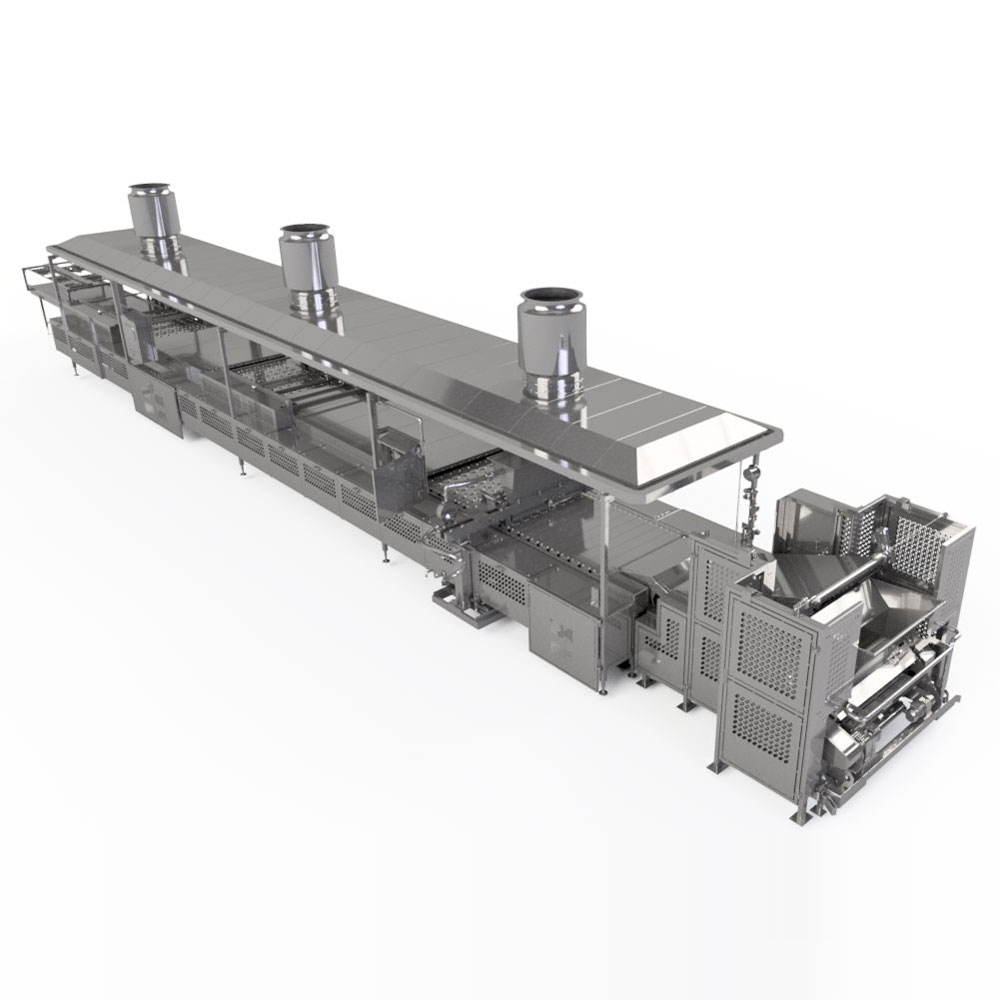

French Fries Frying Machine Two-Stage Feeding (Minimum Height) Vertical Packaging System

Two-Stage Feeding (Minimum Height) Vertical Packaging System