Round Tin Cans Production Line - Chinese Manufacturer, Factory, Supplier

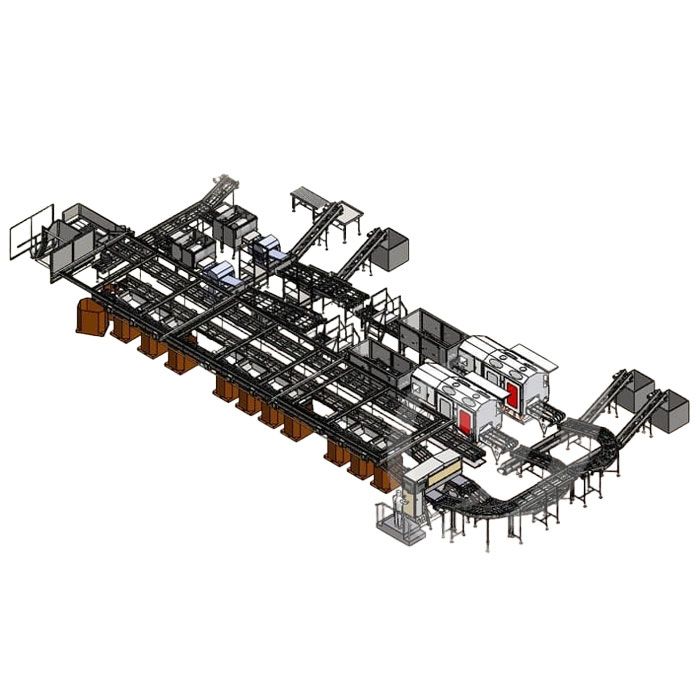

The round tin cans production line is a highly automated system designed to manufacture food-grade and industrial packaging cans with consistent quality and efficiency. It integrates advanced technologies for sheet processing, can body forming, coating, seaming, and leak testing, ensuring that every can meets international packaging standards.

✅ Key Features

Multi-size Compatibility: Supports a wide range of round can diameters and heights.

High Automation: Covers the entire process including sheet cutting, welding, coating, necking, flanging, beading, seaming, and quality inspection.

Robust Build: Made with stainless steel and durable alloys to withstand long production cycles.

Smart Operation: PLC-controlled system with touchscreen interface for simple and efficient adjustments.

Energy Saving: Optimized structure that reduces power consumption while maintaining output.

✅ Production Process

Tinplate Sheet Cutting & Feeding

Can Body Welding / Seam Locking

Internal & External Coating + Drying

Necking, Flanging, and Beading

Seaming and End Lid Application

Leak Testing and Final Inspection

✅ Application Areas

Food Industry: Sardines, mackerel, meat, fruit, vegetables, sauces, condensed milk, powdered foods.

Beverage Industry: Coffee, tea, malt drinks, energy drinks, craft beer.

Industrial Use: Paint, adhesives, lubricants, chemical powders.

✅ Why Choose Round Tin Cans Production Line?

Consistent seam quality ensures airtight and leak-proof packaging.

High adaptability for various can specifications.

Scalable capacity for small, medium, and large manufacturers.

Designed to meet HACCP, ISO, and international packaging standards.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Braised Pork Belly Can Production Line

Braised Pork Belly Can Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Small Scale Banana Chips Production Line

Small Scale Banana Chips Production Line Commercial Electromagnetic Cooker

Commercial Electromagnetic Cooker Dough Kneader Machine

Dough Kneader Machine Portable Flake Ice Machine

Portable Flake Ice Machine Pork Skin Removing Machine

Pork Skin Removing Machine Automatic Dumpling Making Machine

Automatic Dumpling Making Machine