Pasta Making Equipment Factory - Chinese Manufacturer, Factory, Supplier

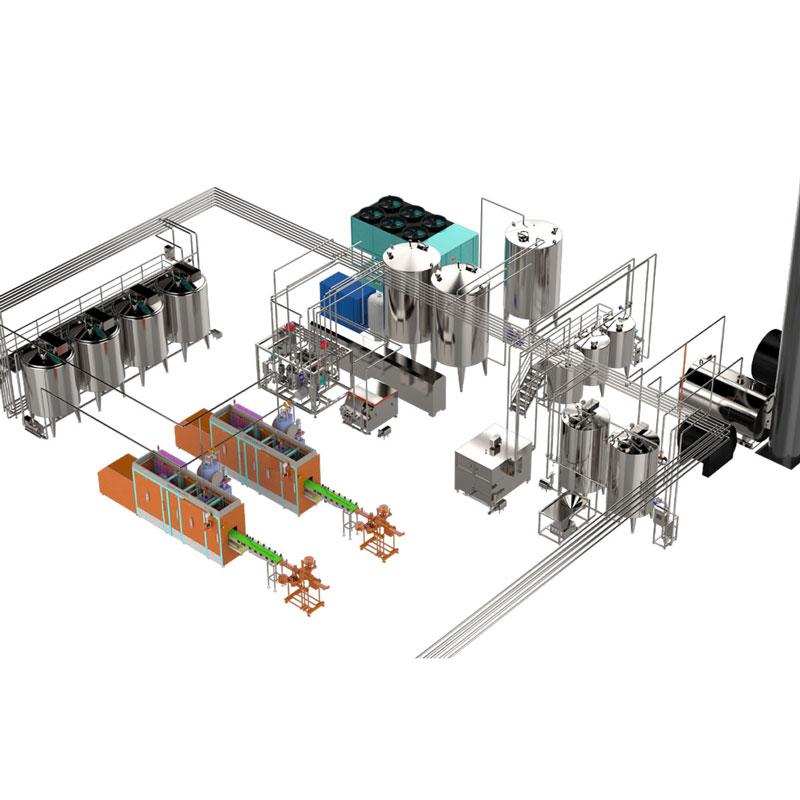

A trusted Pasta Making Equipment Factory is more than a machinery supplier—it is a strategic partner for pasta producers aiming to achieve superior quality, scalable output, and operational efficiency. In commercial pasta production, every step from dough preparation to shaping and drying demands precision, and the right equipment makes this possible at scale.

Within a specialized Pasta Making Equipment Factory, machines are designed with integrated processes that streamline production. Industrial dough mixers ensure uniform hydration, advanced extruders form pasta with perfect density, and interchangeable dies allow manufacturers to produce a wide variety of shapes—from spaghetti and penne to intricate specialty cuts—without extensive changeover times.

Durability and hygiene are paramount. A professional Pasta Making Equipment Factory uses food-grade stainless steel and seamless fabrication to meet strict safety certifications such as HACCP and ISO 22000. Smooth surfaces, sanitary welds, and easy-access panels allow for rapid cleaning and maintenance, reducing downtime and maintaining production schedules.

Technology is a defining advantage. Modern pasta-making lines from leading factories incorporate PLC touch-screen controls, automated ingredient dosing, temperature regulation, and precision cutting systems. These features not only improve consistency but also reduce material waste, ensuring a higher yield per batch.

Customization is another strength of a reputable Pasta Making Equipment Factory. Equipment can be tailored to specific production capacities, facility layouts, and product types, with seamless integration into existing drying and packaging lines. This flexibility ensures that manufacturers can adapt to changing consumer demands and market trends without costly overhauls.

Beyond manufacturing, a high-quality Pasta Making Equipment Factory provides complete lifecycle support—installation supervision, operator training, preventive maintenance, and rapid spare parts supply—to keep production lines running efficiently for years.

For pasta producers seeking to expand capacity, introduce new product lines, or improve operational efficiency, partnering with a skilled Pasta Making Equipment Factory is an investment in long-term success. The combination of advanced engineering, hygienic design, and dedicated service ensures not only consistent product quality but also the agility to grow in competitive global markets.

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Machine

Pasta Machine Multifunction Pasta Machine

Multifunction Pasta Machine Frozen Food Production Line

Frozen Food Production Line Meat Smoking Machine

Meat Smoking Machine Fully Automatic Meat Can Production Lines

Fully Automatic Meat Can Production Lines Fresh Meat Slicing Portioning Machine

Fresh Meat Slicing Portioning Machine Flour Mixing Machine

Flour Mixing Machine Automatic Dumpling Making Machine

Automatic Dumpling Making Machine Yogurt Production Line

Yogurt Production Line Mayonnaise Production Line

Mayonnaise Production Line