Single Channel Food Process Line Price - Chinese Manufacturer, Factory, Supplier

A single channel food process line is a preferred choice for many food factories, OEM contract manufacturers, and equipment distributors when upgrading production or building new lines. Its price is primarily influenced by several key factors:

Production Capacity – Daily, hourly, or per-batch output requirements directly determine the scale and configuration of the production line. Small to medium-capacity lines are ideal for factories with lower annual output or frequent product changes, while high-capacity lines cater to centralized, high-speed production needs.

Automation Level – Semi-automatic models require some manual intervention, resulting in lower initial equipment investment but higher ongoing labor costs. Fully automated models handle feeding, forming, cooking, cooling, and packaging with minimal human input, which means higher upfront investment but significantly reduced labor and management costs in the long run.

Material and Manufacturing Standards – Food-grade stainless steel 304/316L is the standard material for global food machinery. Grade 316L offers superior corrosion resistance, making it suitable for high-salt or acidic foods. Some high-end lines use special coatings or surface treatments on food-contact areas to enhance hygiene and ease of cleaning.

Functional Module Configuration – Requirements for forming, cooking (steaming, boiling, frying), cooling, and packaging vary among buyers. Specialized products—such as premium frozen foods or functional health snacks—may require additional inspection, weighing, or secondary packaging modules, which add to the total cost.

From a market perspective, Chinese-made single channel food process lines offer a significant cost-performance advantage internationally. For B2B buyers, the investment for a standard configuration typically ranges from USD 18,000 to USD 65,000, while high-end, fully automated systems with advanced control and integrated inspection functions can exceed USD 100,000.

Chinese manufacturers generally provide equipment that complies with CE, ISO9001, and HACCP standards, and can adapt designs to meet specific regulatory requirements in the buyer’s country. In addition, many suppliers offer complete after-sales support, spare parts availability, remote technical assistance, and on-site training—ensuring that clients can install, commission, and start stable production in the shortest possible time. This often allows a return on investment within 12–24 months.

For B2B companies seeking to increase capacity and ensure product consistency within limited space and budget constraints, a single channel production line represents a highly cost-effective investment.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

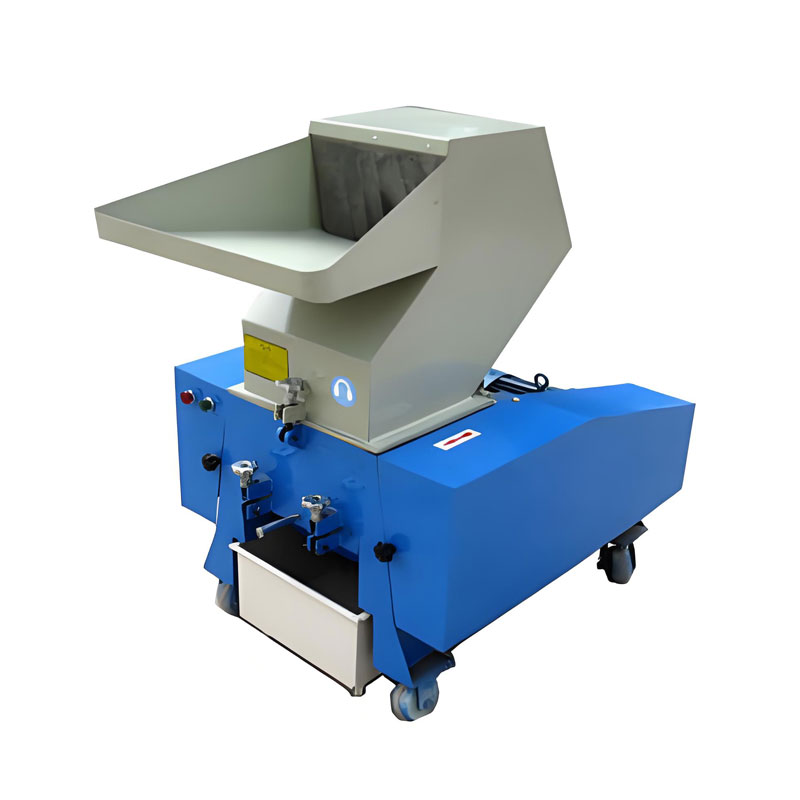

Meat Canned Food Production Line Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Small Scale Banana Chips Production Line

Small Scale Banana Chips Production Line Chicken Nugget Processing Line

Chicken Nugget Processing Line Standard Integrated Weighing and Packaging Machine

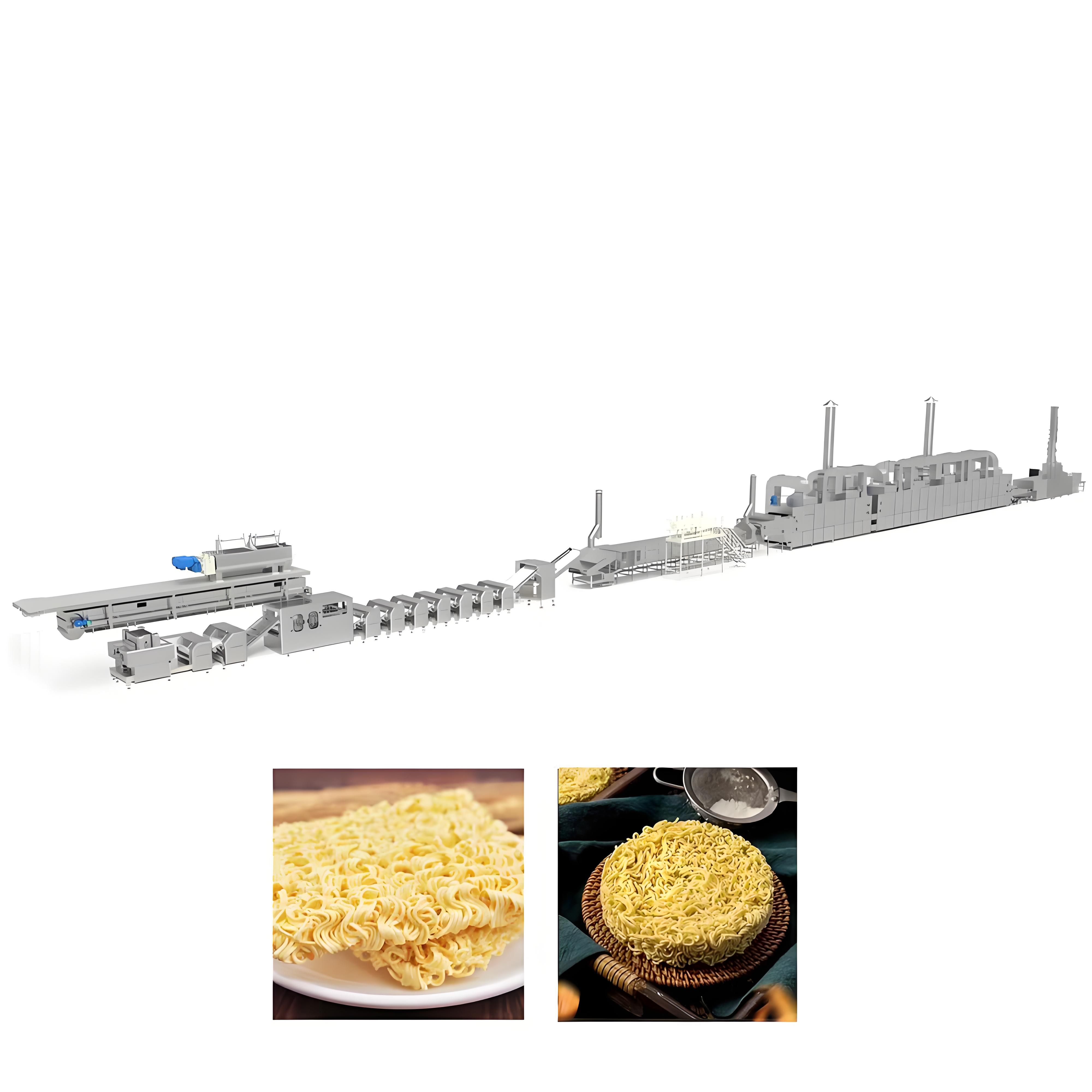

Standard Integrated Weighing and Packaging Machine Deep-Fried Instant Noodle Production Line

Deep-Fried Instant Noodle Production Line Automatic Belt Frying Machine

Automatic Belt Frying Machine Yogurt Making Machine

Yogurt Making Machine Single Tank Single Basket Electric Fryer

Single Tank Single Basket Electric Fryer