Pasta Manufacturing Equipment - Chinese Manufacturer, Factory, Supplier

In today’s competitive food industry, Pasta Manufacturing Equipment must do more than simply produce noodles—it must deliver precision, efficiency, and adaptability to keep pace with shifting consumer tastes and market demands. The latest generation of equipment is engineered not only for high output but also for recipe flexibility and flawless product consistency.

Advanced Pasta Manufacturing Equipment integrates critical production stages into a cohesive process. Dough preparation systems ensure optimal hydration and gluten structure, while extrusion units maintain consistent pressure and temperature for uniform pasta density. Quick-change die assemblies make it possible to switch between shapes—spaghetti, rigatoni, fusilli, or custom designs—without lengthy downtime, giving producers the agility to diversify their product lines.

For processors, hygiene is non-negotiable. High-grade stainless steel construction, polished surfaces, and minimal horizontal joints reduce contamination risks, while tool-free disassembly speeds up sanitation between runs. Compliance with global standards like HACCP and ISO 22000 ensures food safety is built into every stage of production.

What sets top-tier Pasta Manufacturing Equipment apart is the use of intelligent controls and automation. PLC systems synchronize extrusion, cutting, and drying parameters, adjusting in real time to maintain ideal moisture and texture. This level of control reduces waste, lowers labor dependency, and guarantees repeatable results even at high volumes.

Scalability is built into the design. Modular equipment configurations can be installed in small production units or expanded into large-scale industrial plants, integrating seamlessly with packaging lines and quality inspection systems. This adaptability allows manufacturers to grow capacity without replacing their core machinery.

A strong supplier of Pasta Manufacturing Equipment also provides more than hardware. They offer process optimization consulting, operator training, preventive maintenance programs, and rapid spare parts delivery—ensuring continuous, efficient operation and protecting your investment over time.

For pasta producers seeking to meet rising demand while protecting brand reputation, choosing the right Pasta Manufacturing Equipment is a strategic decision. With the right system in place, manufacturers can produce high-quality pasta at scale, respond quickly to market trends, and maintain the consistency that customers expect.

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Machine

Pasta Machine Multifunction Pasta Machine

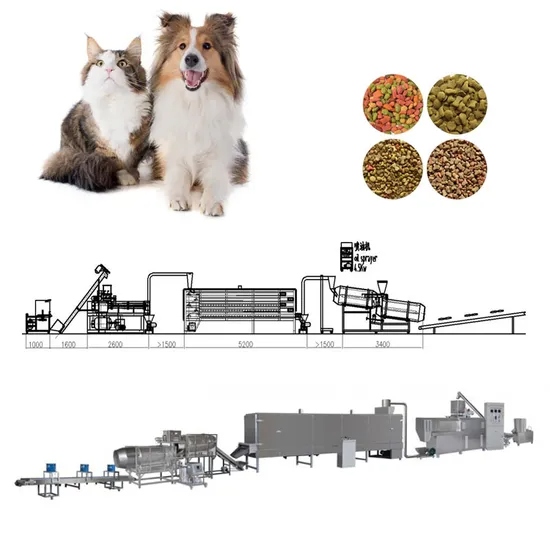

Multifunction Pasta Machine Dry Pet Food Production Line

Dry Pet Food Production Line Small Scale French Fries Production Line

Small Scale French Fries Production Line Blast Freezer

Blast Freezer Gizzard Defatter

Gizzard Defatter Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Milk Production Line

Milk Production Line Cookie Production Line

Cookie Production Line SY-168 / SY-158 Commercial Ice Shaver Machine

SY-168 / SY-158 Commercial Ice Shaver Machine