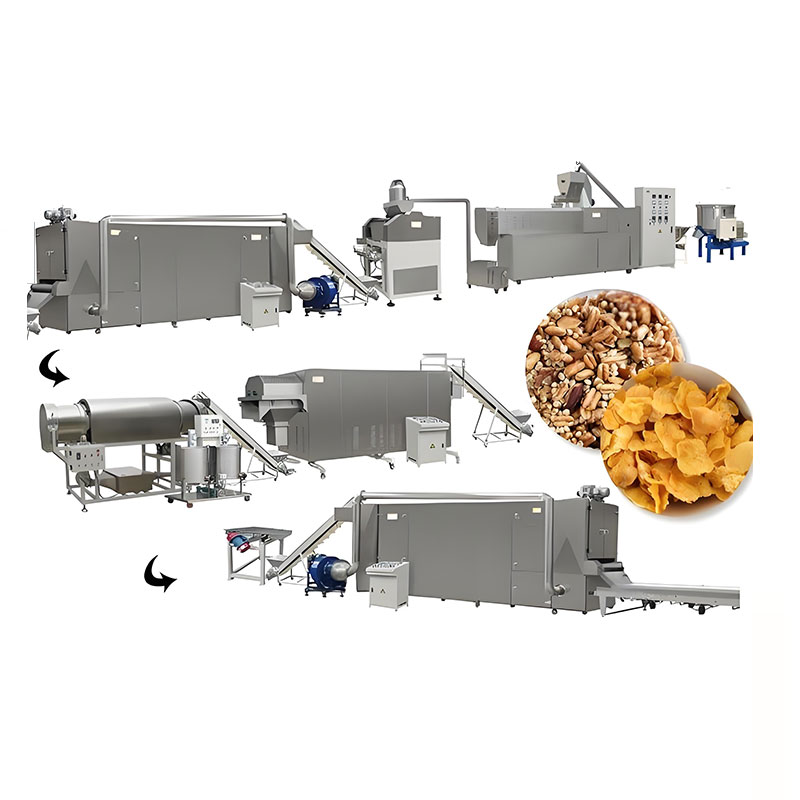

Small Corn Flakes Making Machine - Chinese Manufacturer, Factory, Supplier

The small corn flakes making machine is designed for startups, local brands, and research centers that need a compact yet efficient solution for producing crispy and nutritious corn flakes. With a typical output of 30–100 kg/h, it is well-suited for small-scale production or pilot testing before scaling up to industrial levels.

Built with a compact and space-saving design, the machine integrates key processes such as mixing, extrusion, flaking, drying, and toasting into a streamlined system. The use of stainless steel construction ensures durability and full compliance with international food hygiene standards. Its semi-automatic operation makes it user-friendly, requiring minimal training and easy maintenance.

This machine is particularly attractive for businesses that want to enter the breakfast cereal market without making a large initial investment. It allows flexible recipe adjustments, enabling the production of plain, sweetened, or flavored corn flakes. Optional seasoning and coating units can also be added to diversify product offerings.

In addition to small food factories, research institutes and R&D centers benefit from this equipment for developing and testing new cereal formulations. Its efficiency, low energy consumption, and quick installation make it a practical choice for limited-scale operations.

In summary, the small corn flakes making machine provides a cost-effective and versatile entry point into cereal manufacturing. It offers the perfect balance between affordability, performance, and scalability, making it ideal for businesses preparing to meet the rising consumer demand for ready-to-eat cereals.

Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Corn Canning Production Line

Corn Canning Production Line Corn Flakes Food Production Line

Corn Flakes Food Production Line Automatic Sausage Linking Machine

Automatic Sausage Linking Machine YL-508L Aluminum Foil Dedicated Metal Detector

YL-508L Aluminum Foil Dedicated Metal Detector Meat Shredding Machine

Meat Shredding Machine Automatic Can Sealing Machine

Automatic Can Sealing Machine Pancake Production Line

Pancake Production Line Pasta /Macaroni Making Line

Pasta /Macaroni Making Line Canned Sardine Production Line Equipment

Canned Sardine Production Line Equipment Meat Cuber Machine

Meat Cuber Machine