Overview

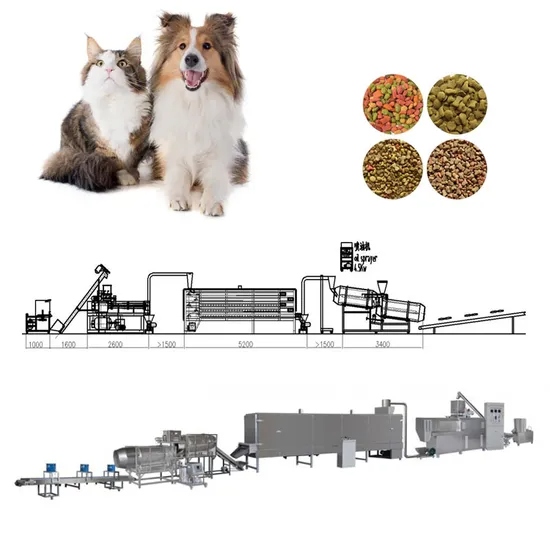

The Dry Pet Food Production Line is an advanced automatic system for manufacturing dog food, cat food, fish feed, and small animal feed.

It integrates mixing, extrusion, drying, coating, cooling, and packaging into one continuous production process, ensuring consistent product quality, optimal nutrition, and efficient operation.

This line is designed for commercial pet food factories and feed manufacturers seeking high automation, flexible recipes, and compliance with food-grade standards (HACCP / ISO22000 / CE).

All parts in contact with food are made of SUS304 stainless steel, providing durability, hygiene, and ease of cleaning.

Production Flow

1️⃣ Ingredient Mixing

Various raw materials (corn flour, rice flour, meat powder, fish meal, vitamins, and minerals) are automatically weighed and mixed to ensure uniform nutrition distribution.

2️⃣ Extrusion & Cooking

A twin-screw extruder cooks and shapes the pet food under controlled temperature and pressure.

This process enhances digestibility, texture, and product expansion rate — suitable for different animal species and sizes.

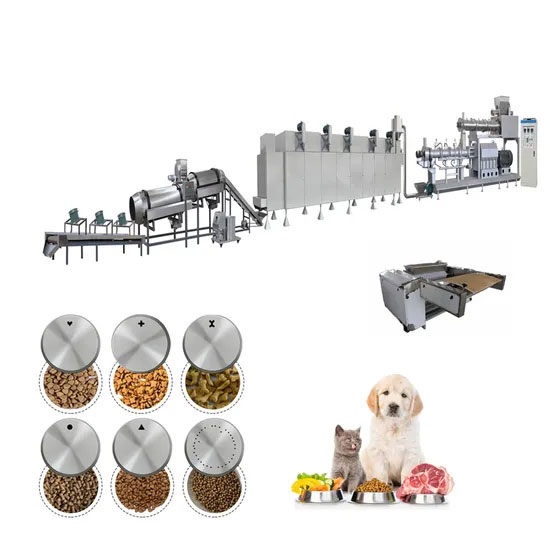

3️⃣ Cutting & Shaping

The rotating cutter attached to the extruder forms pellets in different shapes — round, bone, heart, or custom molds — depending on customer requirements.

4️⃣ Drying

The extruded feed is sent into a multi-layer hot-air dryer, which removes excess moisture to extend shelf life and prevent microbial growth.

5️⃣ Oil Spraying & Flavoring

After drying, the products are evenly coated with animal fat, palatability enhancers, or vitamins using an oil spraying drum to improve flavor and nutrition.

6️⃣ Cooling

A vibration cooling conveyor brings product temperature down to ambient levels, ensuring stability before packing.

7️⃣ Weighing & Packaging

Automatic weighing and packaging machines fill and seal the finished dry pet food into bags or pouches, ready for storage and sale.

Key Features

✅ Full Automation – PLC and touch-screen control system with real-time monitoring

✅ Flexible Product Range – Suitable for various pet species and pellet sizes

✅ Energy Efficient – Optimized heat utilization and air circulation in dryers

✅ Stable Quality – Uniform moisture, density, and texture in final products

✅ Sanitary Construction – Entire line made of SUS304 stainless steel

✅ Customizable Capacity – Available from 150 kg/h to 5,000 kg/h

Technical Parameters

| Parameter | Specification |

|---|---|

| Capacity Range | 150–5,000 kg/hour |

| Material | SUS304 Stainless Steel |

| Extruder Type | Twin-Screw Extruder |

| Control System | Siemens PLC + Touch Screen |

| Heating Method | Electric / Steam / Gas |

| Drying Temperature | 90–150°C Adjustable |

| Pellet Size | 1–15 mm (Customizable) |

| Cooling Type | Air Cooling / Vibration Cooling |

| Power Supply | 380V / 50Hz (Customizable) |

| Warranty | 12–24 Months |

Applications

Dog & cat food manufacturers

Aquatic feed plants (fish, shrimp, etc.)

Small animal feed producers (hamster, rabbit)

Pet food OEM / ODM factories

Research & formulation laboratories

Optional Equipment

Raw material crusher and mixer

Automatic weighing & feeding system

Twin-screw extruder

Rotary dryer (multi-layer type)

Oil and flavor coating drum

Vibrating cooling system

Automatic weighing and packing machine

Dust collection and CIP cleaning unit

Product Types Supported

🐶 Dog Food – High-protein or energy-balanced formulations

🐱 Cat Food – Rich in taurine, vitamins, and meat flavor

🐟 Fish Feed – Floating and sinking pellets with adjustable density

🐰 Small Pet Feed – Nutritionally optimized small-size pellets

Advantages

Turnkey Plant Design — From raw material system to packaging section

Recipe Flexibility — Adjustable formulation for different species

High Nutrient Retention — Controlled cooking process reduces loss of vitamins

Consistent Shape & Texture — High-precision cutting and drying control

Low Operating Cost — Energy-efficient and low labor requirement

Global Service Support — Installation, training, and spare parts supply

Why Choose Our Pet Food Production Line

✅ 15+ years of expertise in food and feed extrusion systems

✅ Proven performance in Asia, Africa, Europe, and South America

✅ Customized solutions for capacity, formulation, and packaging type

✅ Full compliance with HACCP, CE, ISO22000 standards

✅ Energy-saving design with automatic temperature and pressure control

Must-read blogs for bosses