🥔Overview

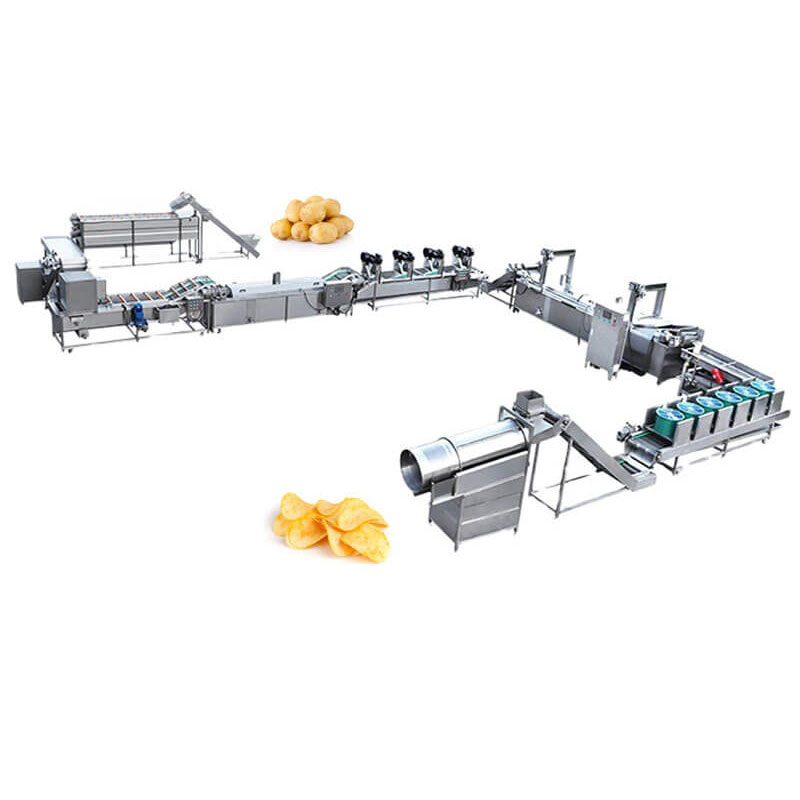

Our Potato Processing Line provides a complete turnkey solution for the cleaning, peeling, cutting, blanching, frying, drying, and packaging of potatoes.

Whether you are producing french fries, potato chips, mashed potatoes, or frozen diced potatoes, this line ensures consistent quality, high efficiency, and superior hygiene.

Built with SUS304 stainless steel and advanced automation, it’s suitable for industrial food processors, frozen food plants, and snack manufacturers seeking scalable production with minimal labor input.

Production Flow

1️⃣ Sorting & Grading

Fresh potatoes are fed onto a sorting conveyor or roller grader to remove stones, mud, and defective pieces — ensuring uniform size and shape for processing.

2️⃣ Washing & Cleaning

A bubble washing machine and rotary washer thoroughly clean the potatoes, removing dirt and surface impurities. Optional ozone or chlorine disinfection systems enhance food safety.

3️⃣ Peeling

Potatoes are peeled using abrasive drum peelers or steam peelers for large-scale operations. The peeling process is efficient and gentle, minimizing product loss.

4️⃣ Cutting / Slicing / Dicing

High-speed cutting machines slice potatoes into sticks, chips, cubes, or flakes according to production needs. Adjustable blades ensure uniform dimensions for even frying or cooking.

5️⃣ Blanching

The continuous blanching machine stabilizes color, texture, and reduces starch before frying or freezing.

Temperature and time are precisely controlled to maintain product consistency.

6️⃣ Dewatering / Drying

After blanching, excess moisture is removed by vibrating dewatering conveyors or centrifugal air dryers, ensuring ideal frying or freezing conditions.

7️⃣ Frying (Optional)

For potato chips or french fries production, the continuous frying machine uses precise temperature control and oil filtration systems to ensure golden, crisp results.

8️⃣ Cooling & Freezing (Optional)

For frozen products, the line integrates cooling conveyors and IQF tunnels to lock in freshness and flavor.

9️⃣ Weighing & Packaging

An automatic weighing and packing system ensures accurate portioning and high-speed packaging in bags, pouches, or trays.

Key Features

✅ Modular Structure – Configurable line sections for various potato products

✅ Hygienic Design – Made of SUS304 stainless steel, easy to clean and maintain

✅ Full Automation – PLC + touchscreen control for precision and monitoring

✅ Energy Efficiency – Optimized heating, water recycling, and filtration systems

✅ High Productivity – Stable continuous processing with low labor demand

✅ Customizable Capacity – From 500 kg/h to 10,000 kg/h, scalable for any plant

Technical Specifications

| Parameter | Specification |

|---|---|

| Capacity | 500–10,000 kg/hour |

| Material | SUS304 Stainless Steel |

| Control System | Siemens PLC + Touch Screen |

| Power Supply | 380V / 50Hz (Customizable) |

| Heating Source | Steam / Gas / Electric |

| Washing Type | Bubble + Rotary + Spray |

| Frying Type | Continuous / Batch (Optional) |

| CIP System | Fully Automatic |

| Warranty | 12–24 Months |

Applications

French fries manufacturing plants

Potato chip factories

Frozen diced potato processors

Ready-to-eat meal producers

Central kitchens and catering suppliers

Optional Equipment

Roller sorting machine

Bubble washing and spray cleaning system

Abrasive or steam peeling machine

Multi-functional cutting and slicing machine

Blanching and dewatering system

Frying and oil filtration system

Cooling and IQF freezing units

Weighing, packaging, and labeling systems

Available Potato Solutions

🍟 French Fries Production Line – Cutting, blanching, frying, freezing, packaging

🥔 Potato Chips Line – Slicing, frying, flavoring, cooling, packaging

🥣 Mashed Potato Line – Cooking, mashing, drying, and packaging

🧊 Frozen Diced Potato Line – Cutting, blanching, cooling, IQF freezing

🥗 Ready-to-Cook Potato Line – Cleaning, peeling, slicing, and vacuum packing

Advantages

End-to-End Turnkey System — From design to on-site installation and training

Flexible Layout Design — Customized for available plant space

Consistent Product Quality — Accurate temperature and timing control

Low Operation Cost — Reduced labor, energy, and water consumption

Reliable Performance — Proven installations worldwide

Why Choose Our Potato Processing Line

✅ Over 15 years of engineering experience in food processing systems

✅ Customized design for different potato products and production capacities

✅ Compliant with international standards (HACCP, ISO22000, CE)

✅ Global technical support and on-site installation service

✅ Energy-saving design with automatic CIP cleaning system

Must-read blogs for bosses