Household Canned Fish Processing Equipment - Chinese Manufacturer, Factory, Supplier

We provide household-scale fish canning equipment designed for small businesses, home-based food entrepreneurs, fishermen, and local seafood processors. This type of equipment is ideal for those who need to produce small batches of canned fish products such as sardines, mackerel, tuna, and anchovies, with low investment cost and easy operation.

The household canned fish production setup includes essential processing stages:

Fish cleaning and preparation – simple cleaning tanks and cutting tools for raw fish handling.

Pre-cooking unit – a small electric or gas steaming pot for initial fish cooking.

Manual or semi-automatic filling machine – for placing fish and adding sauce or oil into cans.

Manual or tabletop seaming machine – to securely seal cans.

Compact retort sterilizer – ensuring food safety and shelf stability.

Cooling and labeling section – basic cooling trays and manual labeling tools.

All equipment is made of food-grade stainless steel, easy to clean and maintain, and compliant with basic food safety standards such as HACCP. The design focuses on small size, energy efficiency, and user-friendly operation, making it suitable for home workshops or small-scale seafood production facilities.

This type of solution is perfect for:

Fishermen or cooperatives who want to process their catch directly for added value.

Local food entrepreneurs looking to sell handmade canned fish products in farmers' markets or local stores.

Start-ups testing the market before scaling up to industrial production.

We also provide guidance on plant layout, recipe development, sterilization parameters, and regulatory compliance, ensuring that even small-scale producers can meet food safety and market requirements. With our household fish canning equipment, you can start your own canned fish business with minimal investment, flexible production, and steady growth potential.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

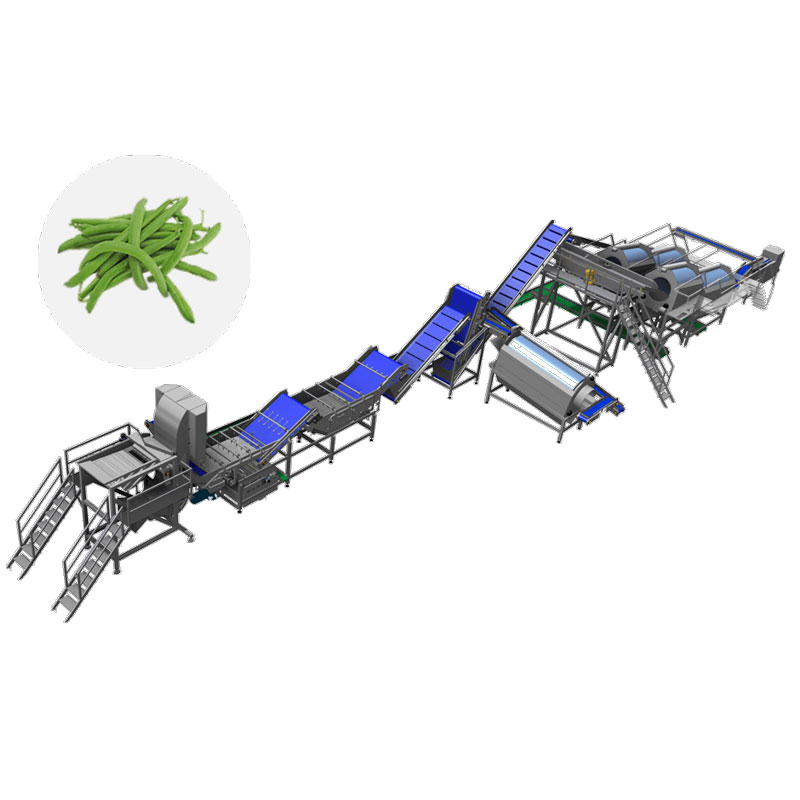

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Meat Tenderizer

Meat Tenderizer Tomato Sauce Milling Machine

Tomato Sauce Milling Machine Spinach Canned Canned Food Canning Production Line

Spinach Canned Canned Food Canning Production Line Multifunctional Noodle Making Machine

Multifunctional Noodle Making Machine Multifunctional Food Packaging Machine

Multifunctional Food Packaging Machine Automatic Fish Filleting Machine

Automatic Fish Filleting Machine Model 330 Frequency Conversion High Speed Chopper

Model 330 Frequency Conversion High Speed Chopper SC Series Bullet Ice Maker

SC Series Bullet Ice Maker