Custom Pasta Making Machine - Chinese Manufacturer, Factory, Supplier

A Custom Pasta Making Machine is not simply equipment—it is a production asset engineered specifically for your recipes, operational flow, and brand ambitions. In pasta manufacturing, where shape, texture, and flavor define market success, tailored machinery offers the precision and flexibility that standard models cannot match.

Every Custom Pasta Making Machine begins with an analysis of your exact production goals. Whether you need to create delicate, thin-cut noodles, rustic bronze-die pasta, or niche products like gluten-free spirals, the system is built to deliver the texture, cooking performance, and visual appeal your market demands.

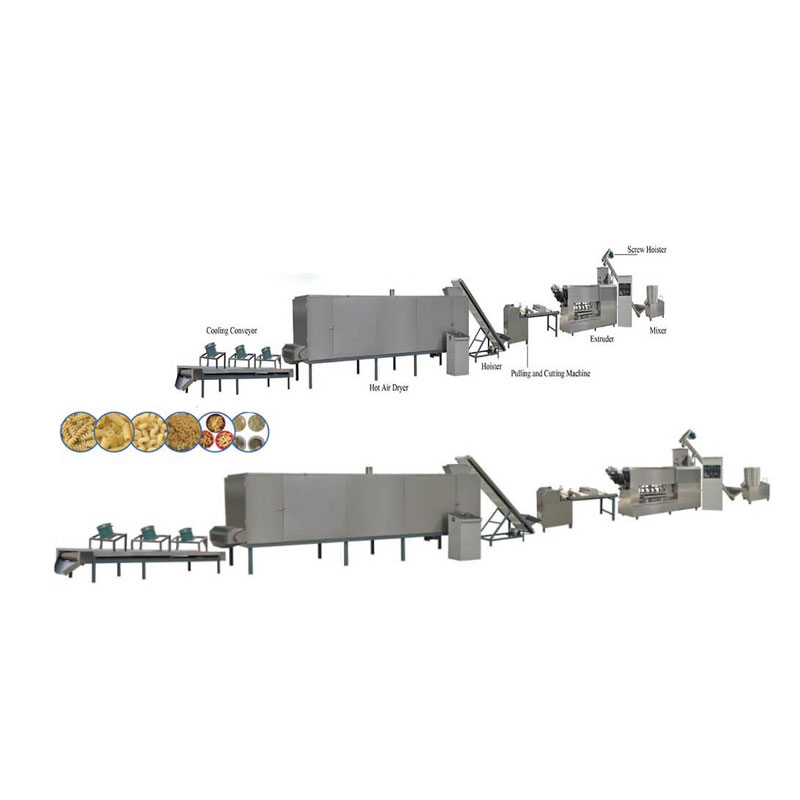

The design goes beyond basic extrusion. Mixing systems are calibrated to maintain ideal dough hydration; extrusion units are tuned to preserve gluten structure; and quick-swap tooling allows a seamless shift between shapes without halting production for extended reconfiguration.

Hygiene is a priority from the ground up. Built from food-grade stainless steel, the Custom Pasta Making Machine features smooth, non-porous surfaces, minimal crevices, and tool-free disassembly points—making thorough cleaning faster and reducing downtime between product runs.

Technology drives consistency. Integrated control systems monitor and adjust parameters such as extrusion pressure, dough temperature, and cutting speed in real time. For high-capacity plants, the machine can link directly to drying tunnels, cooling conveyors, and packaging lines, forming a synchronized, fully automated workflow.

The value of customization is not just in the machine’s configuration—it’s in how it fits your operation. A skilled manufacturer will map your production space, ingredient handling process, and staffing structure, then engineer the equipment for maximum efficiency within those parameters.

Choosing a Custom Pasta Making Machine means investing in production agility. It equips you to launch new product lines quickly, meet evolving consumer tastes, and maintain a consistent quality standard while scaling output.

For pasta producers who see innovation as a growth driver, a custom-built solution transforms production from a fixed process into a responsive, high-performance system tailored to their exact needs.

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Machine

Pasta Machine Multifunction Pasta Machine

Multifunction Pasta Machine Pasta Production Line

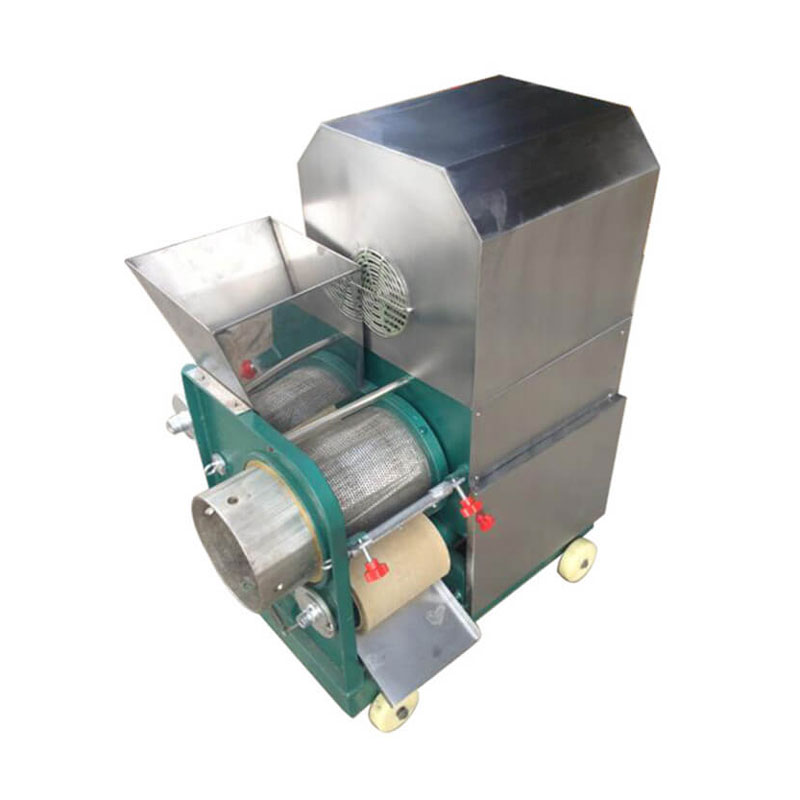

Pasta Production Line Fish Deboner Machine

Fish Deboner Machine Dough Divider Rounder

Dough Divider Rounder Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer Tomato Sauce Machine

Tomato Sauce Machine Milk Production Line

Milk Production Line Stuffed Meatball Machine

Stuffed Meatball Machine Mayonnaise Production Line

Mayonnaise Production Line