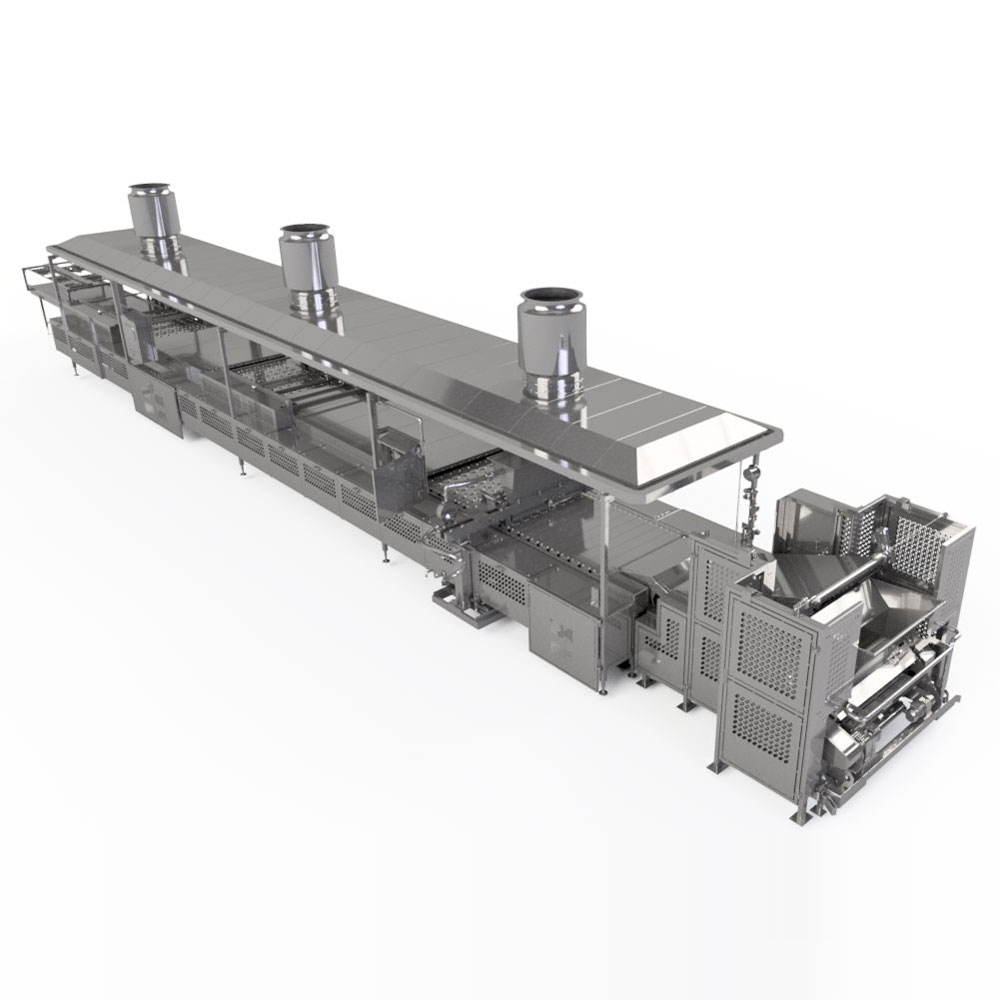

Automatic Solution for Sponge Cake, Cupcake & Layer Cake Manufacturing

The Cake Production Line provides a fully automated and continuous solution for producing various types of cakes — from sponge cakes and cupcakes to Swiss rolls and sliced layer cakes. It integrates batter mixing, depositing, baking, cooling, and packaging processes, ensuring high efficiency, consistent quality, and hygiene for large-scale commercial production.

🏭 Product Overview

This production line adopts PLC control and a modular design, allowing flexible configuration according to different cake types and factory layouts. All parts in contact with food are made of stainless steel SUS304, ensuring durability and compliance with food safety standards. The system can automatically handle batter dosing, filling, baking temperature control, and product conveying, significantly reducing manual labor and ensuring product uniformity.

⚙️ Main Components

| Component | Function Description |

|---|---|

| Batter Mixing System | Automatically blends flour, sugar, oil, eggs, and other ingredients for a consistent texture. |

| Depositing Machine | Precisely deposits batter into trays, cups, or molds with servo-driven accuracy. |

| Tunnel Oven | Uniform hot air circulation ensures even baking and golden crust formation. |

| Cooling Conveyor | Gradual cooling system preserves cake softness and prevents deformation. |

| Filling & Topping Machine | Optional chocolate, cream, or fruit filling station for diverse product lines. |

| Automatic Packaging Machine | Integrates cutting, wrapping, and labeling for final product presentation. |

🍰 Key Features

✅ High Automation Level — Continuous operation from raw materials to finished cakes.

✅ Precise Dosing System — Ensures consistent product size and weight.

✅ Adjustable Baking Parameters — Temperature, speed, and humidity can be fine-tuned for various recipes.

✅ Easy Operation & Cleaning — Touchscreen control with recipe storage and CIP cleaning options.

✅ Flexible Product Range — Suitable for cupcakes, muffins, sliced cakes, and layer cakes.

✅ Stable Quality Output — Designed for 24/7 industrial production with minimal downtime.

📊 Technical Specifications

| Model | Capacity (pcs/h) | Power (kW) | Baking Tunnel Length (m) | Tray Width (mm) | Air Pressure (MPa) |

|---|---|---|---|---|---|

| CPL-300 | 6,000–8,000 | 45 | 15 | 600 | 0.6 |

| CPL-500 | 10,000–12,000 | 60 | 20 | 800 | 0.6 |

| CPL-800 | 15,000–18,000 | 80 | 25 | 1000 | 0.6 |

Customization available according to specific capacity or recipe requirements.

🧁 Applications

This line is widely used for producing:

Cupcakes & Muffins

Layer Cakes

Swiss Rolls

Filled Sponge Cakes

Mini Cakes & Slice Cakes

Applicable for commercial bakeries, food factories, dessert plants, and OEM/ODM manufacturing facilities.

💡 Advantages

✅ Reduces manual labor by 60–70%.

✅ Consistent texture, uniform color, and smooth surface finish.

✅ Suitable for butter-based or egg-based batters.

✅ Compatible with automatic tray feeding and stacking systems.

✅ Energy-efficient oven design lowers operating cost.

✅ Easy integration with cream filling or chocolate coating units.

🧩 Optional Equipment

Cream Filling & Topping Machine

Chocolate Coating System

Ultrasonic Cake Cutter

Automatic Tray Washer

Metal Detector & Check Weigher

📦 Packaging & Delivery

Packaging: Standard export wooden cases.

Delivery Time: 30–45 working days.

Warranty: 12 months.

After-Sales Service: On-site installation, commissioning, and operator training.

🌍 Why Choose Our Cake Production Line

✅ Over 15 years of experience in bakery machinery manufacturing.

✅ Turnkey solutions — from dough preparation to packaging.

✅ CE and ISO9001 certified equipment.

✅ Used by leading cake factories in 40+ countries.

✅ Custom layout design for different plant sizes and product portfolios.

Must-read blogs for bosses