Canned Mackerel Production Line Equipment - Chinese Manufacturer, Factory, Supplier

The Canned Mackerel Production Line Equipment is an integrated and automated solution designed to streamline the entire mackerel canning process — from raw fish receiving to final packaging. This advanced system is widely used by seafood processing plants and large-scale canning factories seeking higher production efficiency, consistent product quality, and strict compliance with international food safety standards such as HACCP, ISO22000, and FDA regulations.

A typical canned mackerel production line includes several key stages: fish thawing and cleaning, grading and cutting, pre-cooking, filling, sauce dosing, sealing, sterilization, cooling, and labeling. Each section is built with high-grade stainless steel (SUS304/316) to ensure corrosion resistance, easy cleaning, and long service life — ideal for continuous operation in marine product environments. Automated weighing and filling machines guarantee portion accuracy, while intelligent sterilization retorts ensure food safety and extended shelf life without compromising taste or texture.

Modern production lines feature PLC control systems with real-time monitoring, data logging, and automatic fault alarms, minimizing manual errors and improving overall productivity. The equipment can be customized for different can sizes, fish species (such as mackerel, sardine, or tuna), and recipe formulations (oil, tomato sauce, brine, etc.), providing strong flexibility for diversified product demands in export markets.

For B2B buyers and seafood processors, investing in a fully automated canned mackerel production line offers significant ROI benefits — reducing labor costs, improving production yield, and ensuring stable product quality. It also helps meet growing global market demand for ready-to-eat canned seafood, which values standardization, traceability, and sustainability in processing.

In short, the Canned Mackerel Production Line Equipment is not just machinery; it’s a complete, scalable production solution for food manufacturers aiming to enhance efficiency, hygiene, and competitiveness in the global seafood processing industry.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Automatic Meatball Making Machine

Automatic Meatball Making Machine Cutting And Stringing Integrated Machine

Cutting And Stringing Integrated Machine Shrimp Canning Line Equipment

Shrimp Canning Line Equipment  Gizzard Defatter

Gizzard Defatter Meat Smoking Machine

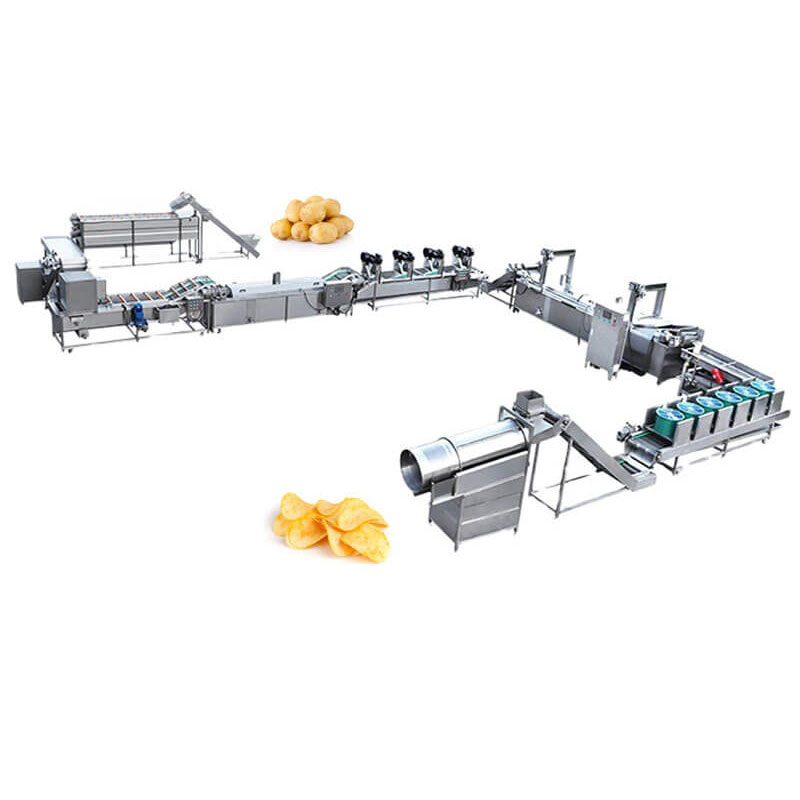

Meat Smoking Machine Crisp Production Line

Crisp Production Line Potato Chips Instant Freezer

Potato Chips Instant Freezer