Chicken Processing Machine - Chinese Manufacturer, Factory, Supplier

The poultry industry’s demand for high-throughput, hygienic, and cost-effective solutions has driven the evolution of advanced Chicken Processing Machines . These systems are engineered to streamline the entire production workflow, from slaughter to packaging, ensuring compliance with global food safety standards. Among the leading innovators in this field is China Yuanlin Factory , a manufacturer renowned for its cutting-edge automation and commitment to delivering scalable solutions tailored to modern processing demands.

Technical Advancements in Poultry Processing

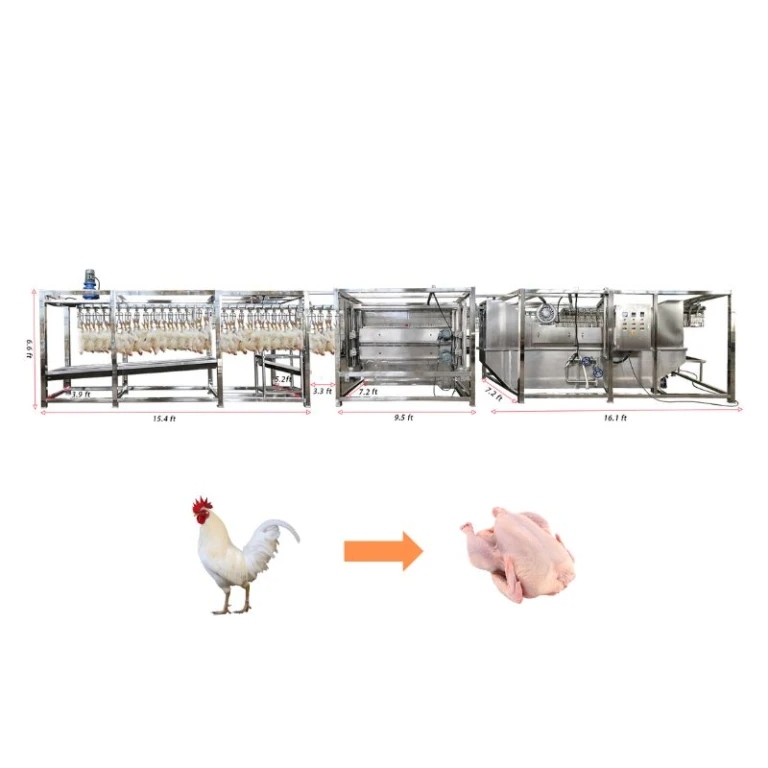

Modern Chicken Processing Machines integrate state-of-the-art technologies such as computerized vision systems and robotic automation to enhance precision. These machines employ HACCP-compliant design principles, minimizing cross-contamination risks through sealed conveyors and stainless-steel construction. The China Yuanlin Factory distinguishes itself by offering modular systems that can be customized to handle varying production volumes, from small-scale farms to large industrial operations. Key features include:

Automated de-feathering systems using advanced scalding and plucking technologies to ensure uniformity.

High-speed evisceration lines with precision-cutting tools to reduce waste and improve meat yield.

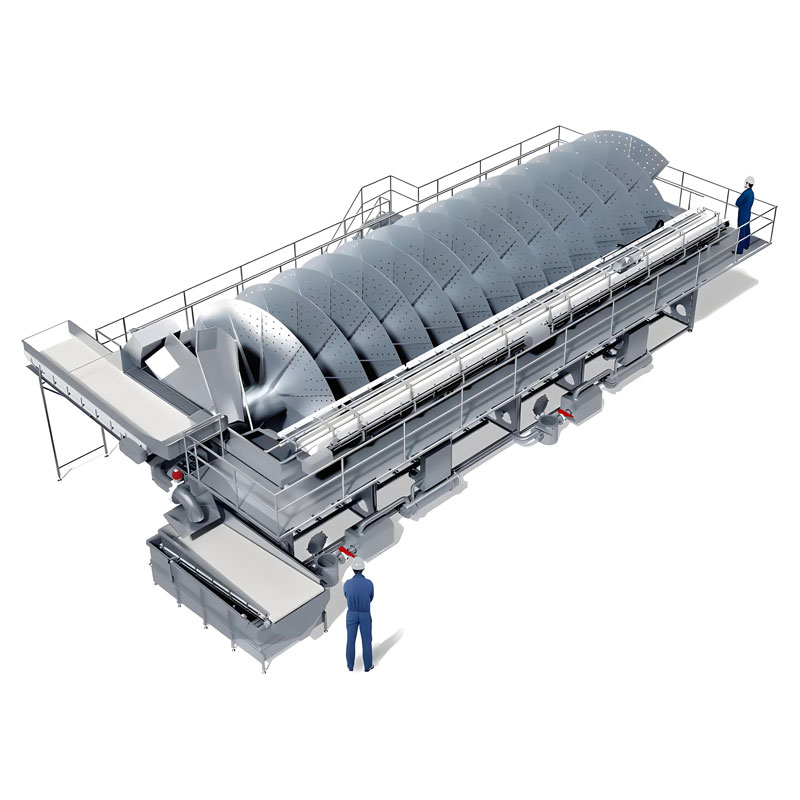

Integrated chilling units that maintain optimal temperatures to preserve product freshness.

Quality Control and Compliance

The Chicken Processing Machine ecosystem prioritizes traceability and hygiene. China Yuanlin Factory ’s machinery incorporates real-time monitoring systems to track critical parameters like temperature, humidity, and conveyor belt speeds. This ensures adherence to stringent regulatory standards, such as USDA and EU directives. Additionally, the use of non-corrosive materials and easy-to-clean surfaces simplifies sanitation protocols, reducing downtime and operational costs.

Scalability and Cost Efficiency

One of the standout advantages of China Yuanlin Factory ’s equipment is its adaptability. The modular design allows processors to expand or reconfigure lines as business needs evolve. For instance, a facility can start with a basic poultry屠宰线 (slaughter line) and later integrate meat grading systems or packaging automation without overhauling the entire setup. This scalability ensures a competitive edge in markets where demand fluctuates seasonally.

Environmental and Ethical Considerations

Sustainability is increasingly critical in food production. China Yuanlin Factory ’s machines emphasize energy efficiency through optimized motor systems and waste-reduction technologies. For example, waste water recycling modules and biodegradable byproduct management systems align with eco-conscious practices. Ethical treatment of poultry is also prioritized, with low-stress handling mechanisms designed to minimize animal distress during processing.

Global Impact and Industry Adoption

The adoption of advanced Chicken Processing Machines has transformed poultry processing into a high-tech industry. China Yuanlin Factory ’s global partnerships highlight its role in empowering farmers and processors across Asia, Africa, and Europe. By reducing labor dependency and enhancing output consistency, these machines are pivotal in meeting the growing demand for affordable, safe poultry products.

In conclusion, the integration of Chicken Processing Machines from manufacturers like China Yuanlin Factory is not merely a technological upgrade—it is a strategic imperative for businesses aiming to dominate the competitive poultry market. Their focus on innovation, compliance, and sustainability ensures that every stage of production is optimized for efficiency, quality, and consumer trust.

Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Automatic Chicken Canned Food Production Line

Automatic Chicken Canned Food Production Line Chicken Production Line

Chicken Production Line Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

Chicken Plucker Machine Chicken Egg Peeling Machine

Chicken Egg Peeling Machine Chicken Feet Peeling Production Line

Chicken Feet Peeling Production Line Small Chicken Feet PeelingMachine

Small Chicken Feet PeelingMachine Big Chicken Feet Peeling Machine

Big Chicken Feet Peeling Machine Chicken Feet Cutting Machine

Chicken Feet Cutting Machine Industrial Microwave Drying Machine

Industrial Microwave Drying Machine Salmon Processing Line

Salmon Processing Line Canned Sardine Production Line Equipment

Canned Sardine Production Line Equipment French Fries Cutting Machine

French Fries Cutting Machine Meat Shredder Machine

Meat Shredder Machine Tomato Juice Processing Production Line

Tomato Juice Processing Production Line Microwave Pigskin Puffing Machine

Microwave Pigskin Puffing Machine Cookie Production Line

Cookie Production Line