Product Overview

The Pet Canned Food Production Line is a fully integrated and customizable processing solution designed for manufacturing wet pet food such as dog food, cat food, meat chunks, pâté, jelly-type products, and meat-in-gravy formulations.

This production line supports various container types including tin cans, aluminum cans, glass jars, and retort pouches.

With flexible automation options—from semi-automatic to fully automated turnkey systems—the line is suitable for new pet food factories, large-scale industrial producers, and traditional plants upgrading to automation.

The entire system complies with HACCP, ISO, FDA, and GMP food safety guidelines. All equipment is made from SUS304/316 stainless steel to ensure hygiene, durability, and compliance with global export standards.

Why Wet Pet Food Factories Choose This Production Line

Wet pet food has grown rapidly due to rising global pet ownership and demand for high-protein, premium nutrition. Pet food manufacturers face several challenges:

Buyer Pain Points We Solve

Inconsistent formula texture

Low production efficiency

Manual filling with poor accuracy

Unstable sterilization causing swelling cans

High labor costs & safety risks

Lack of turnkey engineering support for new factories

This production line solves all of these challenges with automation, stable process control, and a fully integrated workflow.

Core Functions & Technical Advantages

1. Automated Meat Preparation & Mixing System

Designed for high-viscosity, high-protein pet food materials:

High-capacity meat grinder and frozen meat breaker

Vacuum mixer for uniform texture

Jacketed cooker for heating, emulsifying, or blending

Optional particle protection system for chunk-in-gravy products

Ensures stable texture and formula consistency.

2. Precise Filling System for Multiple Formulations

Suitable for:

Pâté

Minced meat

Meat shreds

Chunks in jelly

Chunks in gravy

Meat+vegetable blends

Features:

Servo-driven volumetric filling

Paste filling, high-viscosity filling options

Multi-head systems for high-capacity lines

Accurate dosing with ±1% tolerance

3. Vacuum Sealing & Double-Seam Technology

Ensures can integrity and prevents spoilage:

Tin can seaming

Alu-can sealing

Glass jar capping

Retort pouch sealing (optional)

Vacuum and nitrogen flushing options

Stable sealing reduces oxidation and improves shelf life.

4. Continuous Sterilization (Retort) System

For commercial sterility and long shelf stability:

Water spray or steam retort

Rotary retort for viscous foods

Multi-stage sterilization curves

Precise temperature control (121–135°C)

FDA/CE certified models available

This system prevents swelling, contamination, and under-sterilization.

5. Cooling, Drying & Labeling

After sterilization:

Automated cooling tunnel

Air-drying system

Automatic labeling

Inkjet code printing

Carton packing/sealing

This reduces labor and improves overall efficiency.

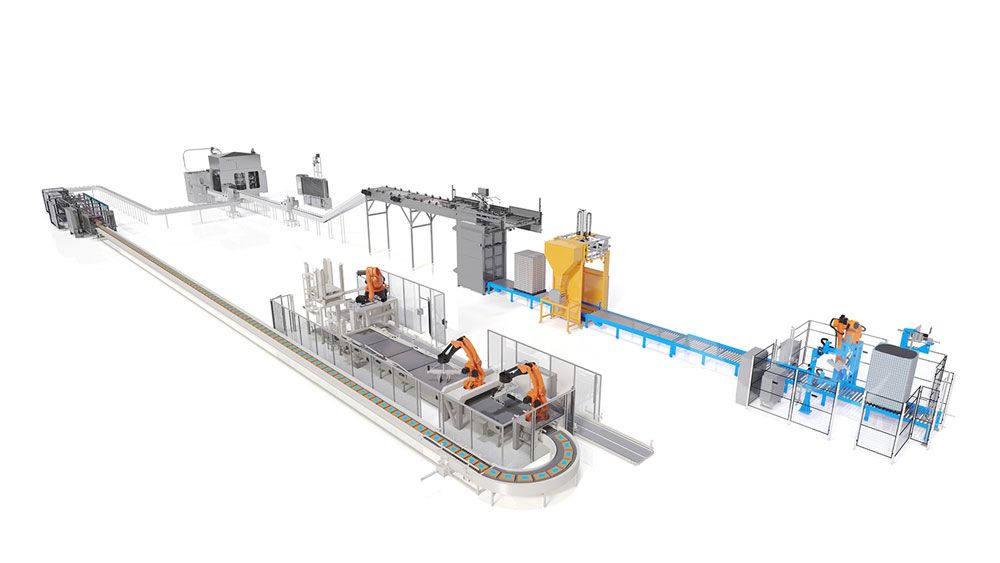

Complete Production Workflow

Below is a standard process flow for cat and dog wet food:

Frozen Meat Breaking → Grinding → Mixing & Blending → Heating/Cooking → Filling → Vacuum Sealing → Sterilization → Cooling → Drying → Labeling → Packing → Warehouse

Each module can be replaced or adjusted depending on the buyer’s recipe and automation level.

Technical Specifications

| Item | Specification |

|---|---|

| Capacity | 500–5000 kg/h |

| Suitable Containers | Tin can, aluminum can, glass jar, retort pouch |

| Filling Accuracy | ±1% |

| Sterilization Temp | 121–135°C |

| Automation Level | Semi-auto / fully automated |

| Power Supply | 220/380V, 50/60Hz |

| Material | SUS304/316 stainless steel |

| Control System | PLC + touchscreen |

Applications

This production line is suitable for manufacturing:

Dog canned food

Cat canned food

Pâté-style wet food

High-moisture soft meat

Meat chunks in gravy

Meat paste with vegetables

High-protein specialty formulations

Applicable for:

Pet food factories

OEM/ODM wet food manufacturers

New plant construction

Traditional processors upgrading automation

Customization Options

We offer full customization for:

Production capacity

Formula type (chunk, paste, mixture, gravy)

Container type & size

Layout design for new factories

Energy type: steam, electricity, or gas

CIP cleaning system

MES/SCADA data monitoring

Integrated packaging line

Engineering team provides detailed 2D/3D layout drawings and turnkey solutions.

Why Choose Us

20+ years of experience in food processing equipment

Exported to more than 40 countries

Turnkey project support

Strong R&D and engineering team

HACCP, ISO, CE compliant machines

On-site installation and training

Lifetime technical support and spare parts

We deliver solutions, not just machines.

FAQ

1. What kind of wet pet food can this line produce?

Pâté, minced meat, chunks in gravy, jelly-style foods, and customized formulas.

2. Can I customize the production capacity?

Yes, from 500–5000 kg/h or more based on your plant size.

3. What containers can the machine work with?

Tin cans, aluminum cans, glass jars, and retort pouches.

4. Do you provide installation and training?

Yes. Our engineers provide global installation, commissioning, and operator training.

5. Is the production line suitable for new factories?

Absolutely. We offer full layout design, equipment integration, and turnkey support.

6. Are spare parts easily available?

All critical components use global brands for easy maintenance and replacement.

Call to Action

Contact us today for a complete turnkey proposal, factory layout, and price quotation.

We help you build a modern, efficient, and profitable pet canned food production plant.

Must-read blogs for bosses