125g Tin Box Fish Canned Production Line - Chinese Manufacturer, Factory, Supplier

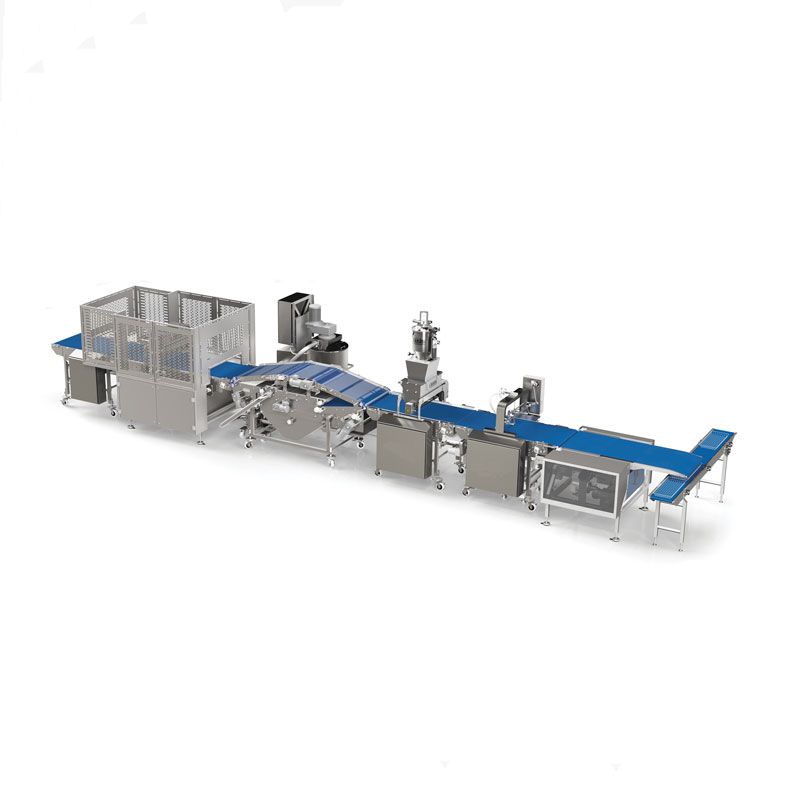

The 125g Tin Box Fish Canned Production Line is a fully automated canning solution specially designed for small-format fish cans widely used in export markets. It is ideal for sardines, mackerel, tuna, and other seafood products packed in 125g rectangular or round tin boxes. The line combines advanced automation with precise control to ensure high productivity, consistent filling accuracy, and excellent food safety throughout the entire process.

Constructed from 304/316 stainless steel, the equipment offers outstanding durability, corrosion resistance, and compliance with HACCP, ISO, and CE standards. The complete line integrates all key stages of fish canning — including raw fish preparation, cooking, cooling, filling, oil or sauce dosing, vacuum sealing, sterilization, cooling, drying, and labeling. Each stage is seamlessly linked via an intelligent conveyor system, minimizing manual handling and maximizing production efficiency.

The automatic filling and sealing unit ensures precise volume control and perfect sealing integrity for every 125g tin can, maintaining product freshness and shelf stability. The retort sterilization system adopts advanced temperature and pressure control to guarantee uniform heat distribution and thorough sterilization, which is essential for long shelf life and export compliance.

This production line can be customized to achieve an output capacity ranging from 1,000 to 15,000 cans per hour, depending on production requirements. Equipped with a PLC-based control system and touchscreen interface, operators can easily monitor performance, adjust parameters, and ensure consistent operation with minimal downtime. Optional systems such as can depalletizers, visual inspection units, automatic labeling, and case packaging equipment can also be integrated for a complete turnkey solution.

As a leading fish canning equipment manufacturer in China, we specialize in providing customized engineering design, installation, commissioning, and operator training for fish processing plants. Our 125g tin box fish canned production line helps seafood processors reduce labor costs, improve yield, and meet international food safety standards, making it a cost-effective and reliable investment for global canned fish manufacturers.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Donut Production Line

Donut Production Line Fish Slicer Machine

Fish Slicer Machine Automatic Can Sealing Machine

Automatic Can Sealing Machine Dairy Processing Lines

Dairy Processing Lines Canned Fish Production Line

Canned Fish Production Line Automatic Fish Filleting Machine

Automatic Fish Filleting Machine Double-Door Steaming Cabinet with Viewing Window

Double-Door Steaming Cabinet with Viewing Window Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven