Overview

The Poultry Processing Line is a fully automated solution designed for efficient slaughtering, evisceration, chilling, and packaging of chicken, duck, and other poultry. It provides an integrated workflow from live bird receiving to final product packaging, ensuring hygiene, speed, and consistency in every stage.

Whether you operate a medium-scale poultry plant or an industrial slaughterhouse, this line can be customized to meet your capacity and local food safety standards.

⚙️ Main Features

✅ Complete Processing Solution

Includes all core sections: live bird reception, stunning, scalding, defeathering, evisceration, washing, chilling, cutting, deboning, weighing, and packing.

Each module can operate independently or in a fully linked system.

✅ Hygienic Stainless-Steel Construction

All equipment is made of SUS304 or SUS316 stainless steel, ensuring corrosion resistance, long service life, and compliance with HACCP, ISO22000, and CE standards.

✅ High Automation & Efficiency

The line integrates PLC control, servo systems, and automatic synchronization between modules — reducing manual handling and maintaining stable throughput up to 12,000 birds per hour.

✅ Precise Evisceration & Carcass Handling

Specially designed evisceration and giblet processing machines minimize product loss and cross-contamination. Ensures high yield and clean, consistent results.

✅ Cooling & Chilling Options

Available in air chilling or water chilling systems, maintaining product freshness while reducing bacterial growth. Temperature and residence time can be precisely controlled.

✅ Flexible Capacity & Layout

Customizable for 500–12,000 BPH, adaptable to local plant layouts. Turnkey engineering support available for layout design, installation, and commissioning.

🧩 Processing Sections

Live Bird Handling System

Conveyor and stunning machine

Automatic scalding & defeathering

Adjustable scalding temperature and rotation speed

Evisceration System

Vent cutter, opener, and eviscerator units

Giblet harvesting (liver, heart, gizzard)

Internal washing and carcass inspection

Chilling & Drip Line

Water or air chilling tunnels

Automated transfer for equal cooling time

Temperature monitoring and control

Cutting & Deboning Section

Wing, thigh, and breast cutting machines

Precision deboning units for yield optimization

Optional portioning and grading systems

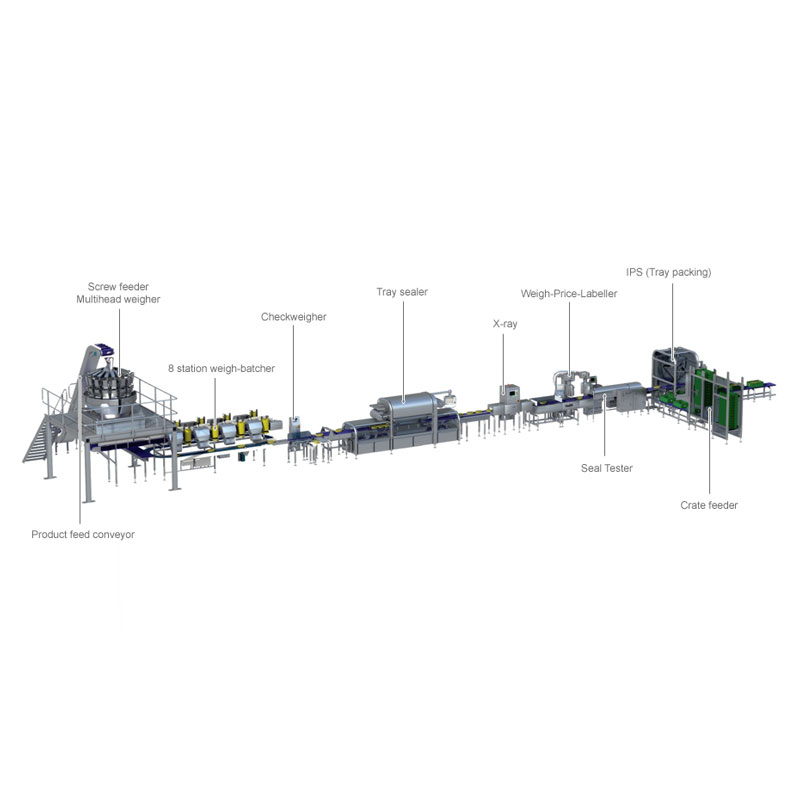

Weighing & Packaging

Automatic weighers, tray sealing, and vacuum packaging machines

Labeling, metal detection, and carton sealing systems

📊 Technical Parameters

| Model | Capacity (Birds/hour) | Main Material | Power | Water Consumption | Dimension (L×W×H) |

|---|---|---|---|---|---|

| PL-500 | 500–1000 | SUS304 | 35 kW | 4–6 m³/h | Customized |

| PL-3000 | 2000–3000 | SUS304 | 65 kW | 8–10 m³/h | Customized |

| PL-6000 | 5000–6000 | SUS304 | 85 kW | 15–18 m³/h | Customized |

| PL-12000 | 8000–12000 | SUS316 | 120 kW | 25–30 m³/h | Customized |

Capacity and dimensions can be customized according to plant requirements.

🔄 Optional Equipment

Automatic giblet processing line

Air or water chilling system

By-product collection system

Portioning and grading machine

Wastewater treatment system

Cold storage integration

🌍 Applications

Chicken processing plants

Duck & goose slaughtering facilities

Integrated poultry meat production factories

Food distribution centers

Export-oriented meat processing enterprises

💡 Advantages

Improve hygiene and reduce contamination risks

Reduce labor intensity and operational cost

Achieve consistent product quality and yield

Support compliance with global standards

Flexible customization for plant size and product type

🧠 Turnkey Support

We provide complete turnkey solutions, including:

Factory layout design and engineering

Installation and operator training

Spare parts and after-sales maintenance

Remote diagnostics and upgrade services

Must-read blogs for bosses